While often presented as a perfect green solution, biomass conversion faces significant disadvantages, particularly with biochemical methods. These processes can be cost-intensive, slow, and struggle with certain types of organic matter like lignin-rich biomass, often resulting in a product that is heavily diluted with water.

The core disadvantages of biomass conversion are not found in the concept, but in the execution. The process is challenged by high costs, the logistical complexity of a bulky and distributed fuel source, and conversion inefficiencies that can undermine its economic and environmental viability at a large scale.

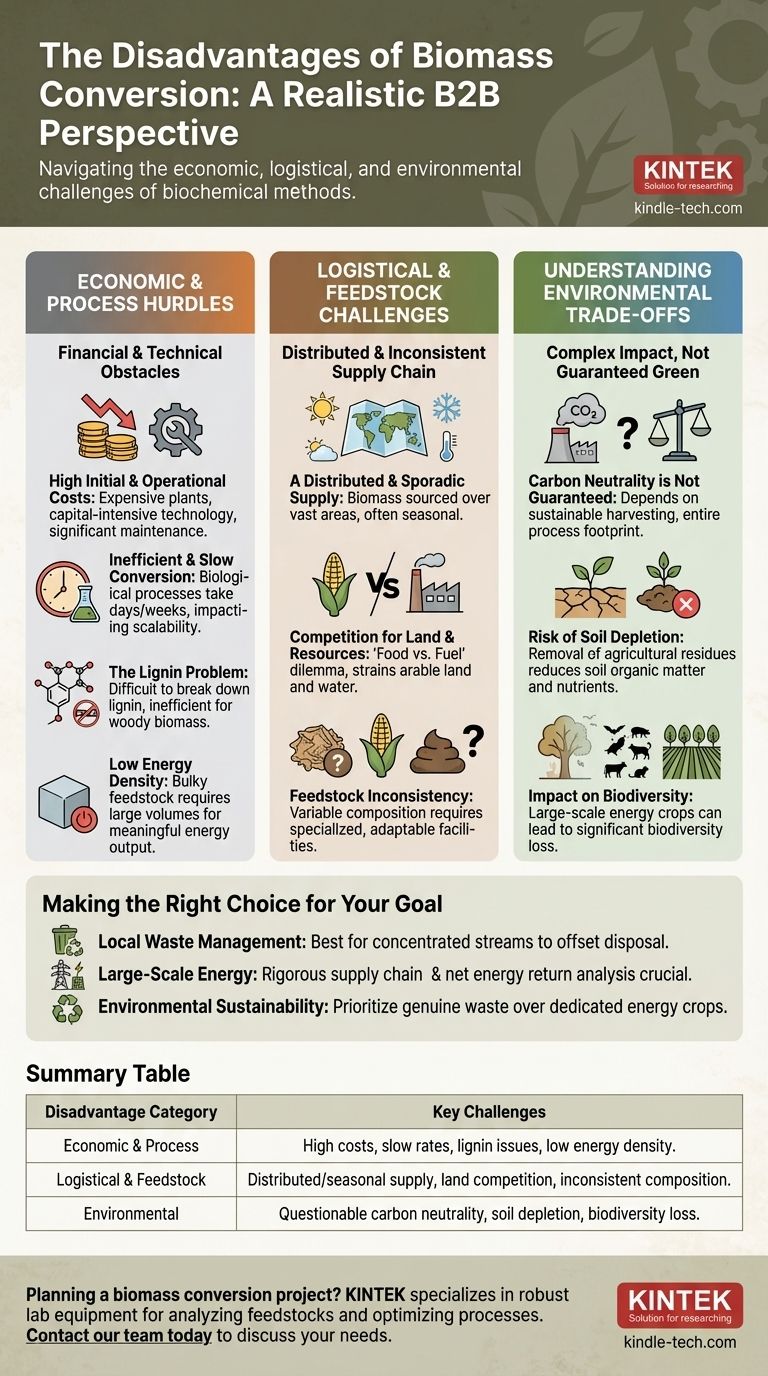

The Economic and Process Hurdles

Biomass appears simple—turning organic matter into energy. However, the financial and technical realities of the conversion process itself present major obstacles that are often underestimated.

High Initial and Operational Costs

Biochemical conversion plants, in particular, are expensive to build and operate. The technologies required for processes like anaerobic digestion or fermentation are capital-intensive, and the ongoing costs for maintenance and operation can be substantial.

Inefficient and Slow Conversion

Many biomass conversion methods are relatively slow. Biological processes can take days or weeks to yield a final product, which impacts throughput and scalability. This contrasts sharply with the on-demand nature of fossil fuels.

The Lignin Problem

A significant portion of plant biomass is lignin, a complex organic polymer that provides structural rigidity. Lignin is notoriously difficult to break down, making many biochemical conversion methods inefficient for woody plants or certain agricultural residues.

Low Energy Density

Biomass is bulky and has a lower energy density compared to fossil fuels. This means large volumes must be collected, transported, and processed to produce a meaningful amount of energy, which adds to the cost and complexity of the entire supply chain.

Logistical and Feedstock Challenges

Unlike coal or natural gas, which can be sourced from a single large mine or well, biomass is inherently distributed and inconsistent. This creates a unique and difficult set of logistical problems.

A Distributed and Sporadic Supply

Biomass sources like agricultural waste are spread over vast geographic areas and are often only available seasonally. Establishing a consistent, year-round supply chain is a major logistical challenge that requires significant infrastructure for collection, storage, and transportation.

Competition for Land and Resources

When biomass demand leads to the cultivation of "energy crops," it can create direct competition with food production for arable land and water. This "food vs. fuel" dilemma is a major ethical and economic concern, potentially driving up food prices and straining resources.

Feedstock Inconsistency

The composition of biomass can vary dramatically depending on the source (e.g., wood chips, corn stover, manure). This inconsistency requires conversion facilities to be highly adaptable or specialized, which can increase complexity and cost.

Understanding the Environmental Trade-offs

The popular image of biomass as purely "green" or "carbon neutral" oversimplifies a complex reality. The true environmental impact depends heavily on how the biomass is sourced and processed.

Carbon Neutrality is Not Guaranteed

While plants absorb CO2 as they grow, burning biomass releases it back into the atmosphere immediately. The claim of carbon neutrality relies on the assumption that the harvested biomass will be replaced by new growth at an equivalent rate. This cycle can be disrupted by unsustainable harvesting, and the entire process—including transportation and processing—generates its own carbon footprint.

Risk of Soil Depletion

Using agricultural residues like corn stalks or wheat straw for biomass means those materials are not returned to the soil. Over time, this can lead to soil nutrient depletion and a decline in organic matter, potentially requiring the increased use of chemical fertilizers.

Impact on Biodiversity

If the demand for biomass drives the creation of large-scale monoculture energy crops, it can lead to a significant loss of biodiversity compared to natural forests or diverse agricultural landscapes.

Making the Right Choice for Your Goal

To properly evaluate a biomass project, you must weigh these disadvantages against its potential benefits for a specific application.

- If your primary focus is local waste management: Biomass can be an excellent solution for converting concentrated waste streams (e.g., from food processing plants or wastewater treatment) into localized energy, directly offsetting disposal costs.

- If your primary focus is large-scale, grid-level energy: You must rigorously analyze the supply chain logistics and net energy return, as these factors are the most common and significant points of failure for large projects.

- If your primary focus is environmental sustainability: Prioritize projects that use genuine waste materials that would otherwise be landfilled, rather than those relying on dedicated energy crops that compete for land.

Ultimately, the viability of biomass conversion depends entirely on matching the right technology to the right feedstock at the right scale.

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Economic & Process | High capital/operational costs, slow conversion rates, inefficiency with lignin-rich biomass, low energy density. |

| Logistical & Feedstock | Distributed & seasonal supply, competition for land (food vs. fuel), inconsistent feedstock composition. |

| Environmental | Questionable carbon neutrality, risk of soil depletion, potential loss of biodiversity. |

Planning a biomass conversion project? Navigating the technical and logistical challenges requires expert knowledge and the right equipment. KINTEK specializes in providing robust lab equipment and consumables for analyzing biomass feedstocks and optimizing conversion processes. Let our expertise help you accurately assess viability and improve efficiency. Contact our team today to discuss your specific needs and find the right solution for your laboratory.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time