At a glance, the primary disadvantages of Diamond-Like Carbon (DLC) coatings are their low thermal stability, their inherent thinness which makes them dependent on the substrate's hardness, and their brittleness, which leads to a low tolerance for impact or surface deformation. While exceptionally hard and slick, DLC is not a universally indestructible armor; it is a specialized surface treatment with clear operational boundaries.

The core limitation to understand is that DLC is a thin-film coating, not a bulk material. Its performance is therefore a function of the entire system: the coating, the substrate it's applied to, and the specific operational environment it faces.

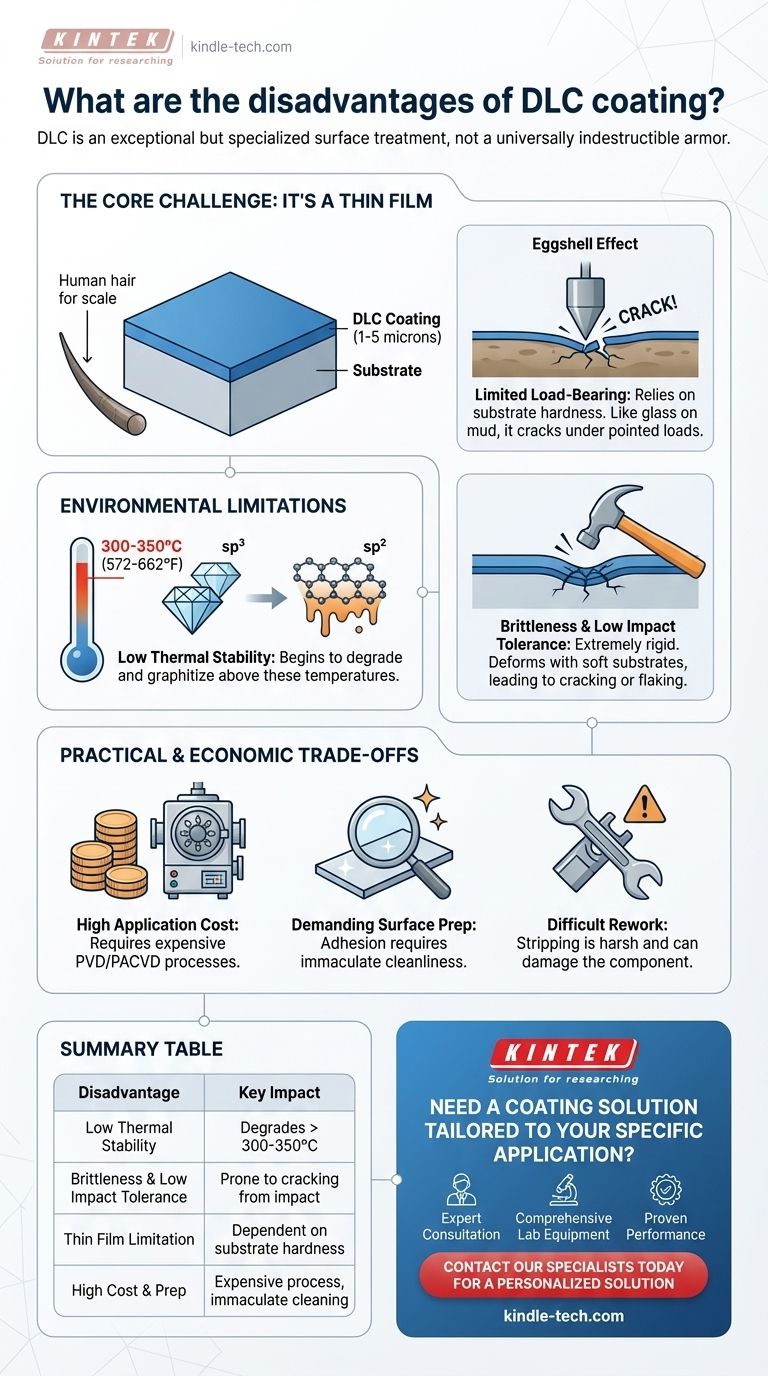

The Core Challenge: It's a Thin Film

DLC coatings are typically only 1 to 5 microns thick—thinner than a human hair. This fundamental characteristic is the source of its most significant limitations.

Limited Load-Bearing Capacity

Because the coating is so thin, it cannot support heavy loads on its own. It relies entirely on the hardness of the material underneath it, known as the substrate.

Applying DLC to a soft substrate (like aluminum or mild steel) is like laying a thin sheet of glass on top of mud. The glass is very hard, but a pointed load will simply push it into the soft base, causing it to crack and fail.

The "Eggshell Effect"

This leads to a high sensitivity to impact. A sharp knock or dent on a DLC-coated part will deform the softer substrate material underneath. Since the DLC film is extremely rigid and not ductile, it cannot stretch with the dent and will crack or flake off around the impact site.

Inability to Mask Imperfections

The thin nature of DLC means it perfectly conforms to the surface it is applied to, including any existing scratches or defects. It cannot be applied in thick layers to fill in gaps or smooth out a rough surface, as high internal stresses would cause a thick layer to delaminate and peel away.

Environmental and Application Limitations

A coating's success depends on its interaction with its environment. DLC performs exceptionally well in some conditions but can be unsuitable in others.

Temperature Sensitivity

Most commercially available DLC coatings begin to break down and lose their hardness at relatively low temperatures, typically around 300-350°C (572-662°F).

At these temperatures, the diamond-like (sp³) carbon bonds begin converting into softer, graphite-like (sp²) bonds. This process, called graphitization, permanently degrades the coating's performance.

While specialized, hydrogen-free, or silicon-doped DLC variants can push this limit higher, temperature remains a primary constraint compared to ceramic coatings like TiN or TiAlN.

Abrasiveness to Softer Materials

In a tribological system (two surfaces rubbing together), a very hard surface running against a very soft one can cause problems. If DLC is paired against a soft counter-face like an aluminum alloy, any microscopic debris can embed into the soft material and then act to abrade the DLC coating, or the hard DLC itself can cause accelerated wear on the softer part.

Understanding the Trade-offs

Beyond its physical limitations, DLC carries practical and economic trade-offs that must be considered during material selection.

Higher Cost

The application of DLC requires a complex vacuum deposition process (PVD or PACVD). This involves expensive equipment, clean-room conditions, and batch processing, making it significantly more expensive than traditional surface treatments like nitriding, phosphating, or hard chrome plating.

Demanding Surface Preparation

Adhesion is everything. For DLC to bond properly, the substrate surface must be immaculately clean and have a specific finish. Any contamination from oils, oxides, or even dust can create a point of failure, causing the coating to flake off in service.

Difficulty of Stripping and Rework

Once applied, DLC is very difficult to remove without damaging the underlying component. The chemical and mechanical stripping processes required are harsh and can alter the part's dimensions or surface finish, making rework a challenging and costly proposition.

Making the Right Choice for Your Application

Choosing a coating requires matching its properties to your primary engineering goal. DLC is an exceptional solution but only for the right problems.

- If your primary focus is reducing friction and sliding wear on a hard, dimensionally stable part: DLC is an elite choice, provided the application temperature remains below 300°C.

- If your application involves shock, high impact, or a soft base material: You must either harden the substrate first (e.g., through nitriding) or select a tougher, more ductile coating.

- If your component operates in a high-temperature environment (above 350°C): Standard DLC is unsuitable, and you should evaluate ceramic coatings (like TiAlN) or specialized high-temperature DLC variants.

- If cost is the primary driver and performance requirements are moderate: More traditional and economical surface engineering processes will likely provide a better return on investment.

Understanding these disadvantages is the key to successfully leveraging DLC's remarkable properties where they can have the most impact.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Low Thermal Stability | Degrades above 300-350°C (572-662°F) |

| Brittleness & Low Impact Tolerance | Prone to cracking or flaking from sharp impacts |

| Thin Film Limitation | Performance is highly dependent on substrate hardness |

| High Application Cost | Requires expensive vacuum deposition (PVD/PACVD) processes |

| Demanding Surface Preparation | Requires immaculate cleanliness for proper adhesion |

Need a Coating Solution Tailored to Your Specific Application?

Understanding the limitations of DLC coating is the first step to selecting the right surface treatment for your components. The experts at KINTEK specialize in helping laboratories and manufacturers navigate these complex material science decisions.

We provide:

- Expert Consultation: Our team will analyze your application's requirements—including temperature, load, and substrate material—to recommend the optimal coating solution.

- Comprehensive Lab Equipment & Consumables: From advanced coating systems to the substrates themselves, KINTEK supplies the high-quality materials and equipment you need for successful surface engineering.

- Proven Performance: Ensure your components meet their performance goals while avoiding costly failures by leveraging our deep industry knowledge.

Don't let coating limitations compromise your project. Contact our specialists today for a personalized solution that maximizes performance and durability.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- Is diamond coating worth it? Maximize Component Life and Performance

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application