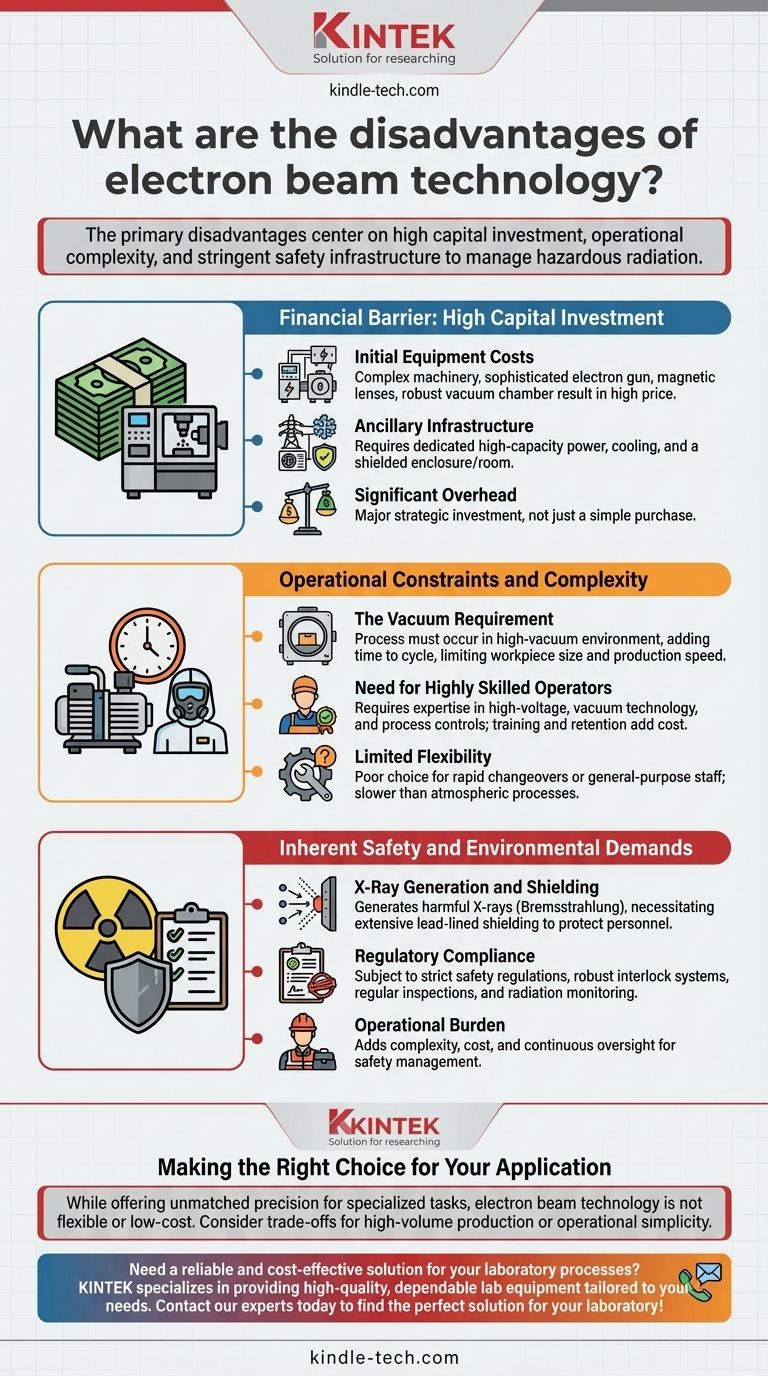

The primary disadvantages of electron beam technology are its significant financial barrier to entry, strict operational requirements, and inherent safety risks. The equipment is exceptionally expensive, requires a vacuum environment that limits workpiece size and production speed, and necessitates highly skilled operators. Furthermore, the process generates harmful X-rays that demand extensive and costly shielding.

While offering unmatched precision and power for specialized tasks, electron beam technology is not a flexible or low-cost solution. Its disadvantages center on high capital investment, operational complexity, and the stringent safety infrastructure required to manage hazardous radiation.

The Financial Barrier: High Capital Investment

Electron beam (EB) systems represent a major strategic investment, not just a simple equipment purchase. The costs extend far beyond the machine itself.

Initial Equipment Costs

An electron beam system is a highly complex piece of machinery. It includes a high-voltage power supply, a sophisticated electron gun, magnetic lenses for focusing, and a robust vacuum chamber. The precision engineering required for these components results in a very high initial purchase price.

Ancillary Infrastructure

Beyond the machine, you must invest in the facility to support it. This often includes dedicated high-capacity power lines, water-cooling systems, and, most critically, a shielded room or enclosure to contain radiation. These infrastructure costs can be as substantial as the equipment itself.

Operational Constraints and Complexity

The day-to-day use of electron beam technology is demanding and imposes significant limitations on workflow and personnel.

The Vacuum Requirement

Electrons are easily scattered by air molecules. To create a focused, high-energy beam, the entire process must occur in a high-vacuum environment. This is the source of several key disadvantages.

First, creating a vacuum takes time, which adds to the total cycle time for each part or batch. This makes EB processes inherently slower than atmospheric processes like laser welding. Second, the workpiece must fit entirely within the vacuum chamber, which imposes strict size limitations.

Need for Highly Skilled Operators

Operating and maintaining an EB system is not a trivial task. It requires personnel with deep expertise in high-voltage systems, vacuum technology, and precise process controls. Finding, training, and retaining these expert operators adds to the ongoing operational cost and complexity.

Inherent Safety and Environmental Demands

The physics behind electron beam technology creates unavoidable safety hazards that must be meticulously managed.

X-Ray Generation and Shielding

When high-energy electrons strike a material, they rapidly decelerate, releasing their energy as X-rays (a phenomenon known as Bremsstrahlung radiation). These X-rays are a serious health hazard.

Consequently, the entire system must be enclosed in a shielded chamber, often lined with lead, to protect personnel. This shielding adds significant weight, cost, and physical size to the installation.

Regulatory Compliance

Due to the generation of ionizing radiation, EB facilities are subject to strict safety regulations and oversight. Compliance requires robust safety interlock systems, regular inspections, and radiation monitoring protocols, adding another layer of operational burden.

Making the Right Choice for Your Application

Choosing to implement electron beam technology requires a clear-eyed assessment of its trade-offs against your specific goals.

- If your primary focus is unparalleled precision or deep penetration: The high costs and complexity are often a necessary trade-off for tasks, like welding thick-section aerospace components or nano-scale lithography, that other technologies cannot perform.

- If your primary focus is high-volume production and low cost-per-part: The batch processing nature and high overhead of EB technology make alternatives like laser processing or conventional manufacturing far more suitable.

- If your primary focus is operational flexibility and simplicity: The need for a vacuum and expert technicians makes EB a poor choice for environments requiring rapid changeovers or operation by general-purpose staff.

Understanding these fundamental constraints is the first step in determining if the power of electron beam technology aligns with your strategic goals.

Summary Table:

| Disadvantage Category | Key Challenges | Impact on Operations |

|---|---|---|

| Financial Barrier | High initial equipment cost, expensive ancillary infrastructure (shielding, power) | Major capital investment, significant overhead |

| Operational Constraints | Requires high-vacuum environment, limited workpiece size, slow cycle times, needs highly skilled operators | Limits production speed and flexibility, increases labor costs |

| Safety & Environmental | Generates hazardous X-rays, requires extensive shielding and strict regulatory compliance | Adds complexity, cost, and operational burden for safety management |

Need a reliable and cost-effective solution for your laboratory processes? While electron beam technology has its place, its high costs and complexity aren't for everyone. KINTEK specializes in providing high-quality, dependable lab equipment and consumables tailored to your specific needs. Whether you're exploring alternatives or need robust support for your existing setup, our expertise ensures you get the right tools for optimal performance and efficiency. Contact our experts today to find the perfect solution for your laboratory!

Visual Guide

Related Products

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Three-dimensional electromagnetic sieving instrument

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What is the fundamental of magnetron sputtering? Master High-Quality Thin Film Deposition

- What is sputtering technology? A Guide to Precision Thin Film Deposition

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What is sputter coating used for? Achieve Superior Thin Films for Electronics, Optics, and Tools

- What is the container that holds the metal source material called in e-beam evaporation? Ensure Purity and Quality in Your Thin-Film Deposition