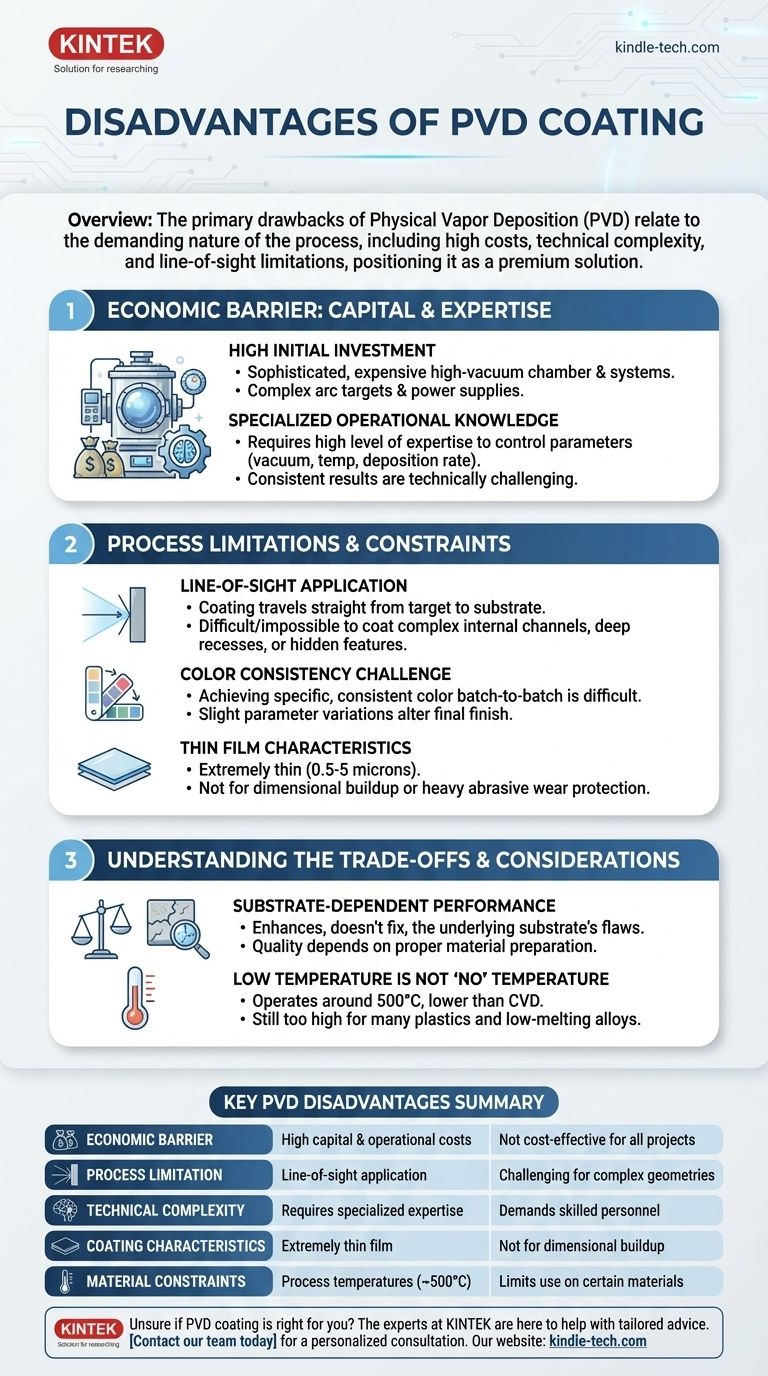

At its core, the disadvantages of Physical Vapor Deposition (PVD) are not related to the quality or performance of the final coating, but to the demanding nature of the process itself. The primary drawbacks are its high capital and operational costs, its technical complexity, and its limitations as a line-of-sight process, which makes coating intricate shapes challenging. These factors position PVD as a premium finishing solution, not a universally applicable one.

While PVD coatings offer superior hardness and corrosion resistance, their disadvantages are practical and economic. The process demands significant investment in specialized equipment and expertise, and its physical constraints mean it is not suitable for all component geometries or budget-sensitive projects.

The Economic Barrier: Capital and Expertise

PVD is a high-vacuum process that requires a significant upfront and ongoing investment, creating a high barrier to entry for in-house application.

High Initial Investment

The machinery for PVD coating is sophisticated and expensive. It requires a large, high-vacuum chamber, powerful pumping systems, and specialized power supplies to vaporize the target material.

As noted in descriptions of advanced PVD machines, these systems are complex, involving multiple arc targets and pulsed bias systems to ensure adhesion and uniformity. This capital expenditure is a primary disadvantage.

Specialized Operational Knowledge

Beyond the equipment, the PVD process demands a high level of expertise to operate and maintain.

Controlling parameters like vacuum level, temperature, and deposition rate to achieve consistent results—especially for specific colors or properties—is a highly technical skill. This adds significant operational cost and complexity.

Process Limitations and Constraints

The physical nature of the PVD process imposes several key limitations that affect its suitability for certain applications.

Line-of-Sight Application

PVD is fundamentally a line-of-sight process. The vaporized coating material travels in a straight line from the source (the target) to the substrate (the part being coated).

This means surfaces that are not directly exposed to the target will receive little to no coating. Coating complex internal channels, deep recesses, or hidden features is often impossible without complex and costly part rotation mechanisms.

The Challenge of Color Consistency

While PVD can produce a variety of decorative colors, achieving a specific, consistent color from batch to batch can be a significant challenge.

Slight variations in process parameters can alter the final finish. This can lead to material wastage and increased costs as operators work to dial in the exact aesthetic required, particularly when using less advanced equipment.

Thin Film Characteristics

PVD coatings are extremely thin, typically between 0.5 and 5 microns. While this is an advantage for preserving the sharpness of cutting tools or maintaining tight tolerances, it is a disadvantage for applications requiring significant dimensional buildup or protection against heavy, abrasive wear.

Understanding the Trade-offs

The disadvantages of PVD are best understood as trade-offs. The same characteristic that is a benefit in one context can be a limitation in another.

Substrate-Dependent Performance

The final properties of a PVD-coated part are directly tied to the quality of the underlying substrate. The coating adheres to and enhances the base material; it does not fix its flaws.

Coating a soft, poorly prepared, or dimensionally unstable material will not yield a durable, high-performance part. The investment in PVD is only realized when applied to a properly engineered and prepared substrate.

Low Temperature Is Not "No" Temperature

PVD is considered a "low-temperature" process, typically operating around 500°C. This is a clear advantage over Chemical Vapor Deposition (CVD), which can exceed 1000°C.

However, this temperature is still too high for many plastics, polymers, and low-melting-point metal alloys, limiting the range of materials that can be coated without risking thermal damage.

Choosing PVD for the Right Reasons

A clear understanding of PVD's limitations is crucial for making an informed decision. Evaluate your project goals against these practical constraints.

- If your primary focus is cost-sensitive mass production: PVD's high initial and operational costs may make it less suitable than other finishing methods like electroplating or painting.

- If your primary focus is coating complex, internal geometries: The line-of-sight nature of PVD presents a significant challenge; consider alternative methods like CVD or electroless nickel plating.

- If your primary focus is restoring worn dimensions: PVD's thin-film nature is not suitable for this task; look to processes like thermal spray or laser cladding instead.

- If your primary focus is ultimate performance on a well-prepared part: PVD is an excellent choice, as its limitations are primarily economic and geometric, not performance-related.

Understanding these inherent process limitations is the key to leveraging PVD's remarkable advantages effectively.

Summary Table:

| Disadvantage Category | Key Limitation | Impact on Application |

|---|---|---|

| Economic Barrier | High capital investment & operational costs | High barrier to entry; not cost-effective for all projects |

| Process Limitation | Line-of-sight application | Challenging for coating complex internal geometries or recesses |

| Technical Complexity | Requires specialized expertise for operation | Adds to operational costs and demands skilled personnel |

| Coating Characteristics | Extremely thin film (0.5-5 microns) | Not suitable for dimensional buildup or heavy abrasive wear |

| Material Constraints | Process temperatures (~500°C) | Limits use on plastics and low-melting-point alloys |

Unsure if PVD coating is the right solution for your specific laboratory or manufacturing needs? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing tailored advice to ensure you select the most effective and efficient coating technology for your application.

Contact our team today for a personalized consultation and discover how KINTEK can support your project's success with the right equipment and expertise.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition