While rotary kilns are the workhorses of high-temperature material processing, they are not without significant disadvantages. Their immense scale and demanding operational environment introduce substantial challenges related to cost, maintenance, and efficiency that must be carefully considered before any investment is made.

A rotary kiln provides unparalleled capability for high-volume, continuous processing at extreme temperatures. However, this power comes with a steep price in the form of high capital and operational costs, intensive maintenance demands, and a large physical footprint.

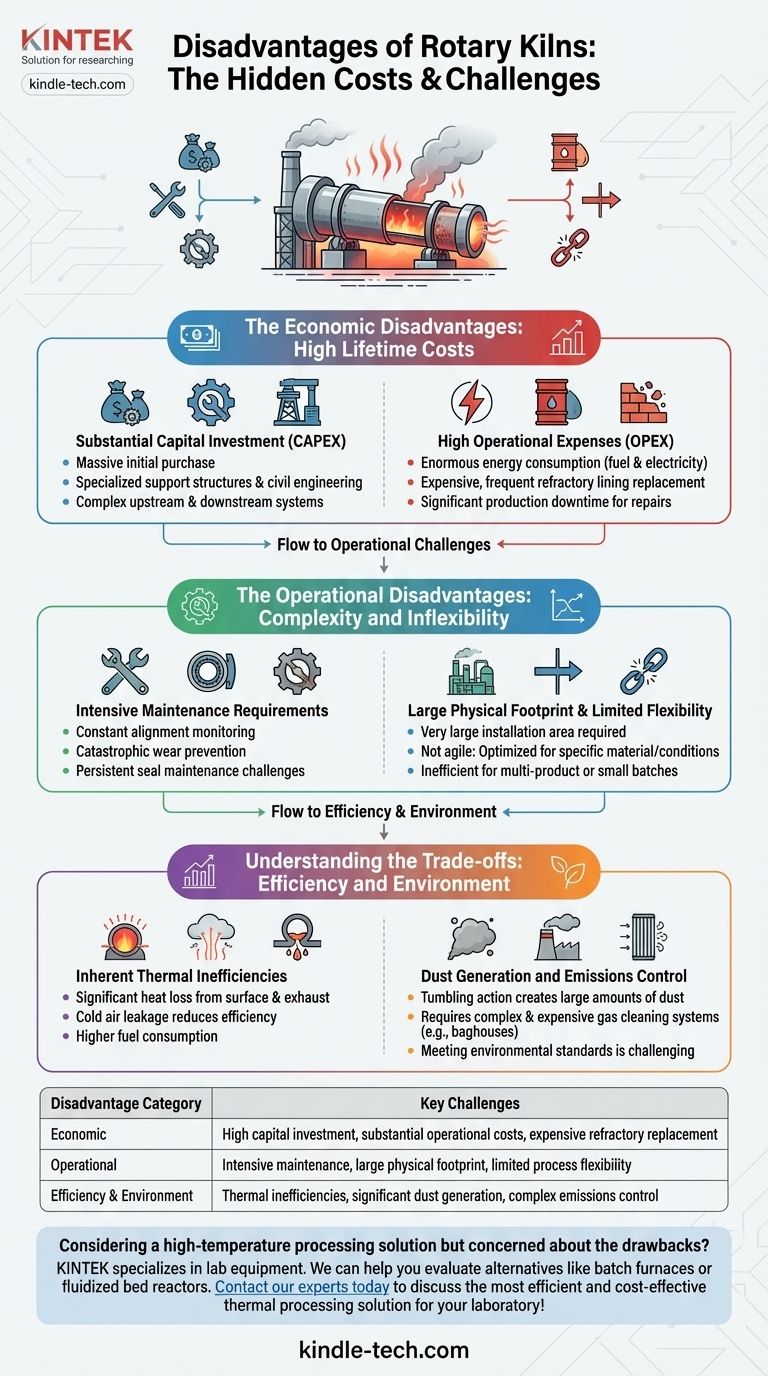

The Economic Disadvantages: High Lifetime Costs

The financial commitment for a rotary kiln extends far beyond the initial purchase. Its entire lifecycle is characterized by significant, recurring expenses.

Substantial Capital Investment (CAPEX)

A rotary kiln is a massive piece of heavy industrial equipment. The initial outlay includes the cost of the large steel shell, specialized support structures (tyres and rollers), the powerful drive system, and extensive civil engineering for the foundation.

Furthermore, the kiln itself is only one part of the system. You must also budget for complex upstream feeding equipment and extensive downstream systems for product cooling and exhaust gas treatment.

High Operational Expenses (OPEX)

The primary operational cost is energy. Bringing large volumes of material to very high temperatures requires a tremendous amount of fuel, and rotating the massive, heavy cylinder consumes significant electrical power.

The refractory lining, which protects the steel shell from extreme heat, is a consumable item. It wears down over time and requires periodic replacement, a process that is both expensive and results in significant production downtime.

The Operational Disadvantages: Complexity and Inflexibility

The day-to-day reality of running a rotary kiln involves constant monitoring and a rigid operational structure.

Intensive Maintenance Requirements

The mechanical integrity of a rotary kiln is critical. The precise alignment of the shell, support rollers, and thrust rollers must be constantly monitored to prevent catastrophic wear and failure.

Seals at the feed and discharge ends are essential for efficiency and safety, yet they are a persistent maintenance challenge. They operate in a harsh environment of high heat, abrasive dust, and constant movement, leading to frequent wear and tear.

Large Physical Footprint

By their nature, rotary kilns are long, horizontal cylinders that demand a very large installation area. The space required for the kiln itself, along with its associated feed, discharge, and gas handling systems, can be a major constraint for any facility.

Limited Process Flexibility

Rotary kilns are typically designed and optimized for a specific material and a narrow range of operating conditions. They are not agile systems.

Changing the feedstock or desired chemical reaction often proves highly inefficient or may require significant and costly re-engineering, making them unsuitable for multi-product or small-batch operations.

Understanding the Trade-offs: Efficiency and Environment

While designed for heat transfer, rotary kilns inherently struggle with efficiency and environmental containment, creating critical trade-offs.

Inherent Thermal Inefficiencies

Despite design features like internal heat exchangers, a significant amount of energy is lost. Heat radiates from the large surface area of the kiln shell to the surrounding environment.

Additionally, a large volume of hot exhaust gas leaves the system, carrying away valuable thermal energy. Imperfect seals that allow cold air to leak into the kiln further reduce its thermal efficiency and increase fuel consumption.

Dust Generation and Emissions Control

The tumbling action inside the kiln, which is essential for good heat transfer, inevitably creates a large amount of dust, especially when processing fine materials.

This dust becomes entrained in the high-velocity exhaust gas, requiring complex and expensive gas cleaning systems (such as cyclones and baghouse filters) to meet environmental emissions standards.

Making the Right Choice for Your Process

A rotary kiln is a specialized tool. The decision to use one must be weighed against its significant long-term commitments.

- If your primary focus is high-volume processing of a consistent feedstock at extreme temperatures: A rotary kiln may be the best or only option, but you must budget for its high lifetime cost and maintenance burden.

- If your primary focus is process flexibility or handling smaller, varied batches: The inflexibility and high cost of a rotary kiln make it a poor choice; alternative technologies like fluidized bed reactors or batch furnaces should be investigated.

- If your primary focus is minimizing operational costs and environmental impact: The kiln's inherent thermal inefficiencies and dust generation must be a central part of your analysis, as they will require major, continuous investment to manage.

Ultimately, choosing a rotary kiln means committing to a system that is powerful but demanding, requiring a deep understanding of its total cost of ownership.

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Economic | High capital investment (CAPEX), substantial operational costs (OPEX), expensive refractory lining replacement |

| Operational | Intensive maintenance, large physical footprint, limited process flexibility |

| Efficiency & Environment | Thermal inefficiencies, significant dust generation, complex emissions control requirements |

Considering a high-temperature processing solution but concerned about the drawbacks of a rotary kiln? KINTEK specializes in lab equipment and consumables, serving diverse laboratory needs. We can help you evaluate alternatives like batch furnaces or fluidized bed reactors that might offer greater flexibility, lower operational costs, and a smaller footprint for your specific application. Contact our experts today to discuss the most efficient and cost-effective thermal processing solution for your laboratory!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product