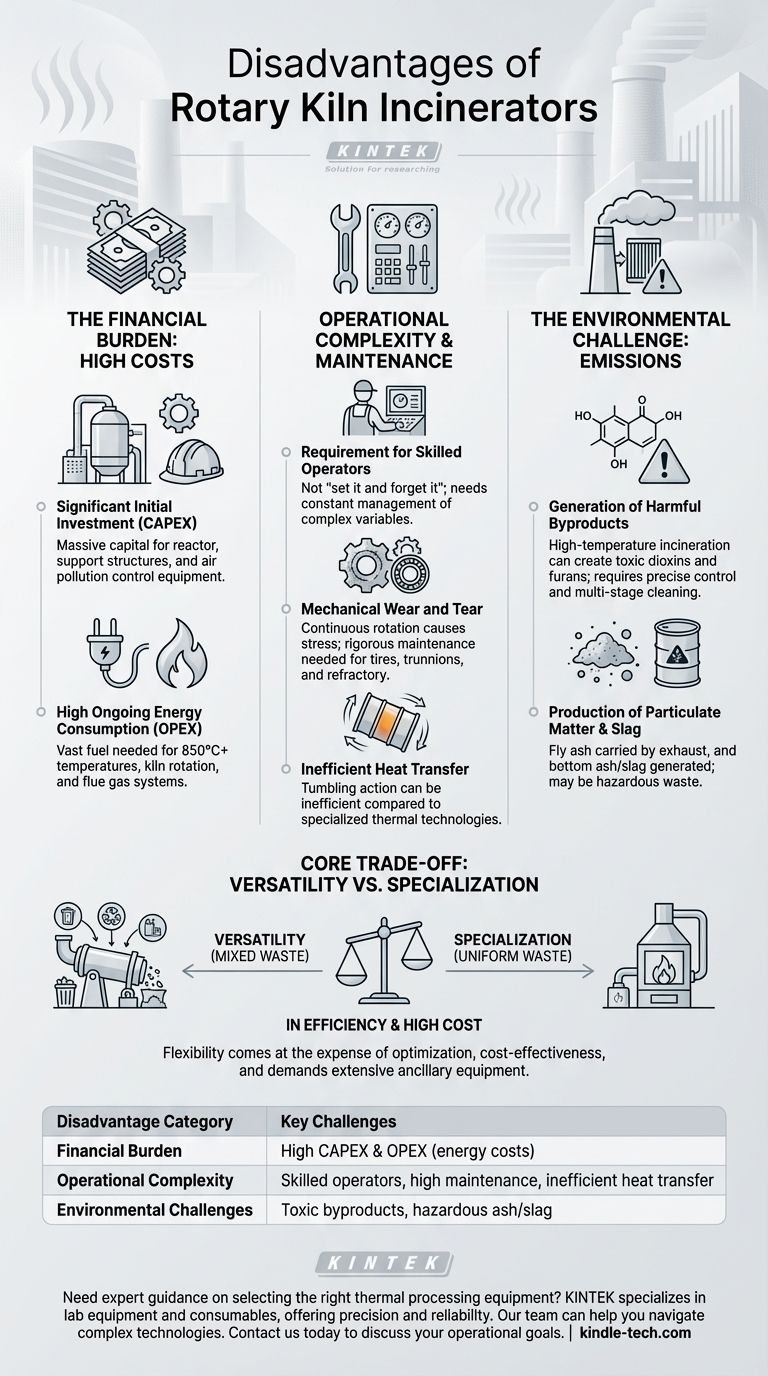

While incredibly versatile, the primary disadvantages of rotary kiln incinerators are their substantial financial cost, high operational complexity, and the significant environmental challenges they present. These systems demand major capital investment for the kiln and its essential ancillary equipment, consume large amounts of energy, and require sophisticated air pollution control systems to manage hazardous emissions.

The core trade-off of a rotary kiln is its versatility versus its complexity. Its unmatched ability to process a wide variety of waste types is balanced by extremely high capital and operational costs, demanding maintenance schedules, and a non-negotiable requirement for extensive downstream environmental controls.

The Financial Burden: High Capital and Operational Costs

Choosing a rotary kiln incinerator is a major financial commitment that extends far beyond the initial purchase. The lifetime cost of the system is a critical factor in any evaluation.

Significant Initial Investment (CAPEX)

A rotary kiln is a massive piece of heavy industrial equipment. The cost of the reactor itself, along with the necessary support structures, feed systems, and extensive air pollution control equipment, results in a very high initial capital expenditure.

High Ongoing Energy Consumption (OPEX)

Reaching and maintaining the high temperatures required for effective incineration (often over 850°C) consumes a vast amount of fuel. This, combined with the energy needed to rotate the heavy drum and power the extensive flue gas treatment systems, leads to significant and continuous operational costs.

Operational Complexity and Maintenance Demands

The robust nature of a rotary kiln belies its operational sensitivity. Effective and safe operation is not a simple task and requires constant oversight.

Requirement for Skilled Operators

These are not "set it and forget it" systems. Proper operation requires a team of highly trained technicians who can manage complex variables like temperature profiles, kiln rotation speed, and waste feed rates to ensure complete combustion and minimize harmful emissions.

Mechanical Wear and Tear

The constant rotation of a massive, heated steel tube creates immense mechanical stress. Key components like the support tires, trunnion wheels, and refractory lining are subject to continuous wear and require a rigorous preventative maintenance schedule to avoid costly, unplanned downtime.

Inefficient Heat Transfer

While the tumbling action is excellent for mixing solids, it can be a relatively inefficient method of heat transfer. This can lead to higher energy consumption compared to other, more specialized thermal treatment technologies designed for uniform waste streams.

The Environmental Challenge: Managing Emissions

By their very nature, incinerators pose environmental risks. The mixed, often hazardous nature of the waste processed by rotary kilns makes managing these risks the single most critical challenge.

Generation of Harmful Byproducts

The high-temperature incineration of varied materials, especially those containing chlorine, can create highly toxic byproducts like dioxins and furans. Preventing their formation and capturing them requires precise combustion control and sophisticated, multi-stage gas cleaning systems.

Production of Particulate Matter and Slag

The combustion process generates fly ash (particulate matter) that is carried out with the exhaust gas and must be captured by filters. It also produces a bottom ash or slag, both of which may be classified as hazardous waste and require specialized, costly disposal.

Understanding the Trade-offs: Versatility vs. Specialization

The decision to use a rotary kiln hinges on understanding its core compromise. You gain flexibility at the expense of optimization and cost-effectiveness.

The "Jack of All Trades" Problem

A rotary kiln's greatest strength—its ability to handle liquids, solids, sludges, and hazardous materials simultaneously—is also a source of its inefficiency. For a single, uniform waste stream, a more specialized and less complex furnace would almost certainly be more efficient and cost-effective.

The Burden of Ancillary Equipment

The kiln itself is just the heart of the system. A fully functional and compliant facility requires a vast array of supporting equipment, including waste preparation and feeding systems, afterburners (secondary combustion chambers), heat recovery boilers, and extensive air pollution control units. These systems add immense cost, complexity, and maintenance load.

Making the Right Choice for Your Goal

Evaluating a rotary kiln requires aligning its inherent drawbacks with the specific nature of your waste management needs.

- If your primary focus is processing a diverse, complex, or hazardous waste stream: The rotary kiln's versatility is likely necessary, and its high costs and complexity are a justifiable trade-off for its capabilities.

- If your primary focus is cost-efficiency for a uniform waste stream: A more specialized technology, such as a fixed hearth or fluidized bed incinerator, will likely offer a lower total cost of ownership.

- If your primary focus is minimizing environmental risk: Be prepared for a massive investment in state-of-the-art flue gas treatment technology, as this is non-negotiable for responsible kiln operation.

Understanding these disadvantages is the first step toward implementing this powerful technology responsibly and effectively.

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Financial Burden | High capital investment (CAPEX), significant ongoing energy costs (OPEX) |

| Operational Complexity | Requires skilled operators, high maintenance due to mechanical wear, inefficient heat transfer |

| Environmental Challenges | Generation of toxic byproducts (dioxins, furans), production of hazardous ash/slag |

| Core Trade-off | Versatility for mixed waste vs. inefficiency and high cost for uniform streams |

Need expert guidance on selecting the right thermal processing equipment for your lab or facility? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and reliability. Our team can help you navigate the complexities of waste treatment technologies to find a solution that balances performance, cost, and compliance. Contact us today to discuss your specific requirements and discover how we can support your operational goals.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker