The primary disadvantages of thermal evaporation are its high levels of film contamination, the low density of the resulting film, and its incompatibility with high-melting-point materials. These issues stem from the method's inherent simplicity, which involves heating the entire source material and its container (a crucible or boat) to the point of vaporization.

While valued for its simplicity and low cost, thermal evaporation offers limited control over the deposition process. This lack of control is the direct cause of its main drawbacks: higher impurity levels and weaker film quality compared to more advanced techniques.

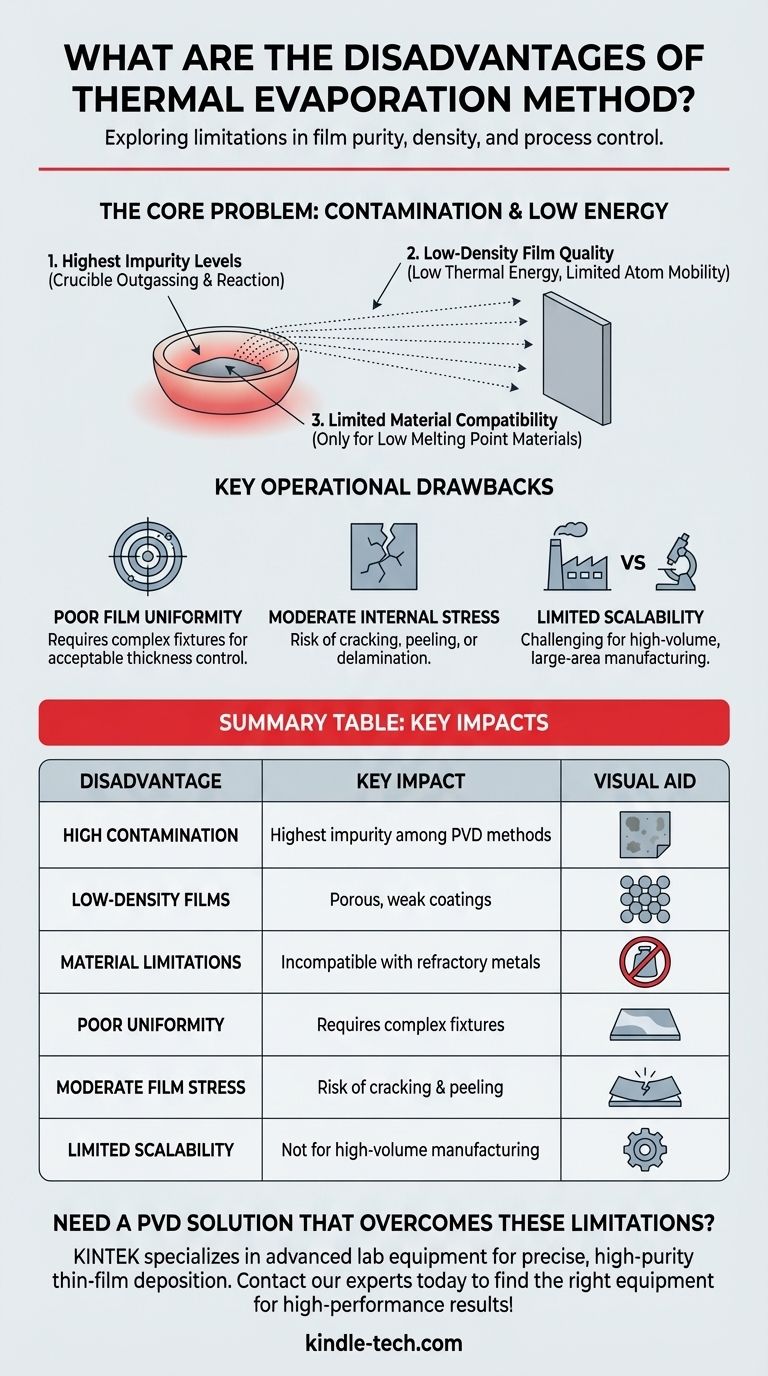

The Core Problem: Contamination and Low Energy

The fundamental limitations of thermal evaporation are a direct result of how it generates vapor. By heating the entire source container, the process introduces variables that are difficult to control, impacting the final film's quality.

The Highest Impurity Levels

Thermal evaporation is known for having the highest impurity levels among all Physical Vapor Deposition (PVD) methods. Because the crucible or boat holding the source material is also heated to extreme temperatures, the container material itself can outgas or react with the evaporant, contaminating the vapor stream and embedding impurities into the deposited film.

Low-Density Film Quality

The atoms that evaporate from the source do so with relatively low thermal energy. When they land on the substrate, they have limited mobility to arrange themselves into a dense, tightly packed structure. This results in films that are more porous and have lower density, which can compromise their mechanical and optical properties. This can be partially improved with techniques like ion-assist, but the base quality remains lower than other methods.

Limited Material Compatibility

This method is only suitable for materials with relatively low melting points, such as aluminum or silver. Materials that require very high temperatures to evaporate, like refractory metals (e.g., tungsten, molybdenum), are not compatible. Attempting to heat these materials would often damage the heating element or crucible before significant evaporation occurs.

Key Operational Drawbacks

Beyond the quality of the film itself, the process has several practical limitations that affect its use in manufacturing environments.

Poor Film Uniformity

Without additional hardware, thermal evaporation produces films with poor thickness uniformity. The vapor naturally follows a line-of-sight path from the source to the substrate, creating a thicker deposit directly above the source and thinner deposits toward the edges. Achieving acceptable uniformity requires complex and costly additions like planetary substrate fixtures and uniformity masks.

Moderate Internal Stress

The films deposited via thermal evaporation often exhibit moderate internal stress. This built-in tension or compression can cause the film to crack, peel, or delaminate from the substrate over time, especially when subjected to thermal cycling.

Limited Scalability

While excellent for lab-scale research and small batch production, the method faces challenges with scalability. Maintaining uniform heating and deposition over very large areas is difficult, making it less suitable for high-volume manufacturing compared to other techniques.

Making the Right Choice for Your Goal

Understanding these disadvantages is critical for selecting the right deposition technique. The choice depends entirely on balancing the need for film quality against budget and material constraints.

- If your primary focus is low-cost deposition of simple metals: Thermal evaporation is an excellent choice for applications like basic electrical contacts or decorative coatings where pristine purity is not the main concern.

- If your primary focus is high-purity, dense films for advanced devices: The inherent contamination and low density make other PVD methods like sputtering or e-beam evaporation a much safer and more reliable option.

- If your primary focus is depositing high-melting-point or refractory materials: This method is fundamentally unsuitable, and you must use a higher-energy process like e-beam evaporation or sputtering.

By aligning the method's capabilities with your project's specific performance requirements, you can avoid costly failures and ensure a successful outcome.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Contamination | Highest impurity levels among PVD methods due to crucible outgassing. |

| Low-Density Films | Porous, weak coatings due to low-energy atom deposition. |

| Material Limitations | Incompatible with high-melting-point materials like refractory metals. |

| Poor Uniformity | Requires complex fixtures for acceptable thickness control. |

| Moderate Film Stress | Risk of cracking, peeling, or delamination over time. |

| Limited Scalability | Challenging for high-volume, large-area manufacturing. |

Need a PVD solution that overcomes the limitations of thermal evaporation?

KINTEK specializes in advanced lab equipment and consumables for precise, high-purity thin-film deposition. Whether you require higher-density coatings, compatibility with refractory materials, or scalable manufacturing solutions, our expertise in sputtering and e-beam evaporation systems can ensure your project's success.

Contact our experts today to discuss your specific application and find the right equipment for high-performance results!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Tungsten Evaporation Boat for Thin Film Deposition

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab