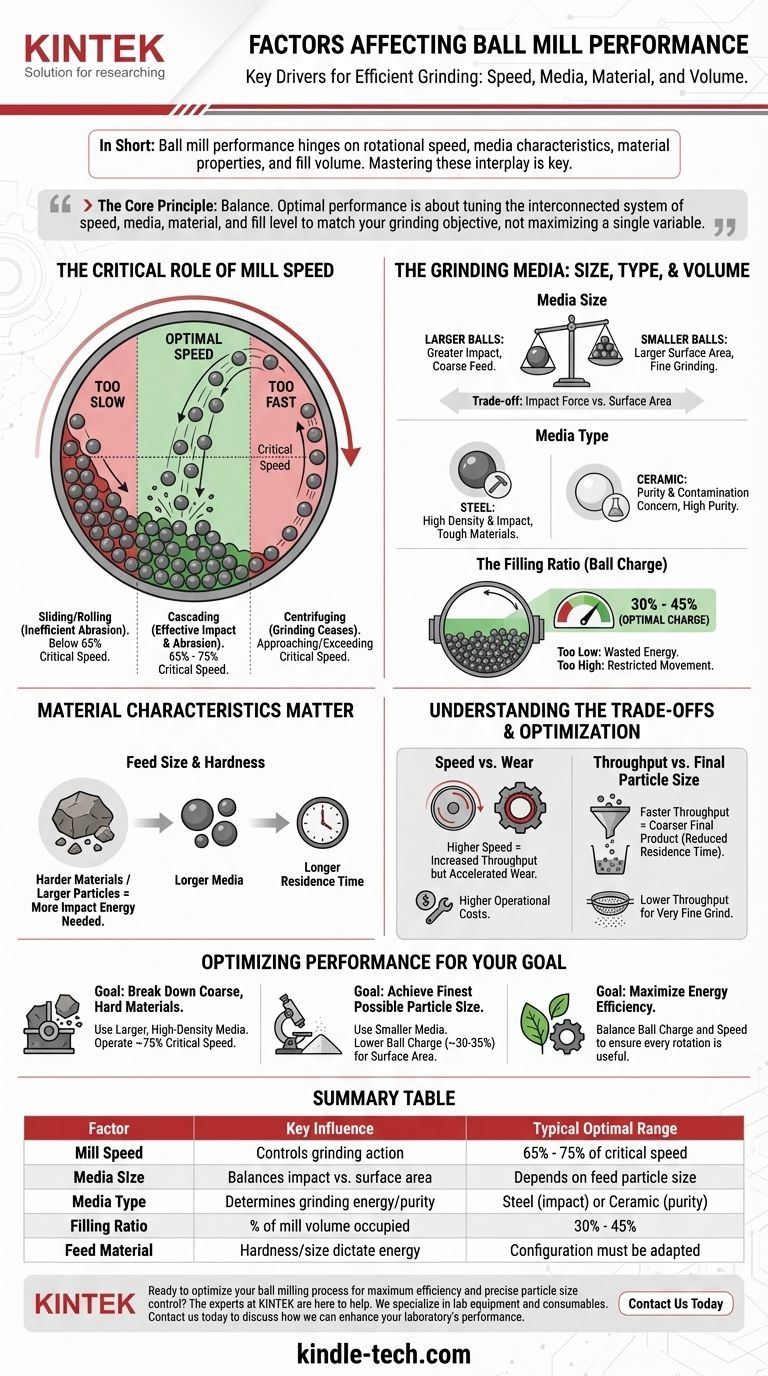

In short, the performance of a ball mill is determined by four primary factors: the rotational speed of the mill, the characteristics of the grinding media (balls), the properties of the material being ground, and the volume of media filling the mill. Mastering the interplay between these elements is the key to achieving efficient and predictable results.

The core principle is one of balance. Optimal ball mill performance is not achieved by maximizing any single variable, but by carefully tuning the interconnected system of speed, media, material, and fill level to match your specific grinding objective.

The Critical Role of Mill Speed

The speed at which the mill rotates directly controls the grinding action. This is arguably the most influential variable and is typically discussed in relation to its "critical speed"—the theoretical speed at which the grinding media would simply stick to the mill's inner wall due to centrifugal force.

Finding the Optimal Speed

Effective grinding occurs when the media are lifted high enough to tumble and cascade down, creating the impact and abrasion needed to break particles. This is usually achieved at 65% to 75% of the critical speed.

The Impact of Too Slow a Speed

If the mill rotates too slowly, the media will simply slide or roll down the side of the mill. This results in an inefficient grinding action dominated by abrasion, significantly increasing the time required to achieve the desired particle size.

The Impact of Too Fast a Speed

Conversely, if the speed approaches or exceeds the critical speed, the media are pinned against the shell by centrifugal force. This condition, known as "centrifuging," prevents the media from tumbling, and grinding action ceases almost entirely.

The Grinding Media: Size, Type, and Volume

The grinding media—the balls themselves—are the instruments of particle size reduction. Their properties are just as crucial as the mill's operating speed.

Media Size: Impact vs. Surface Area

There is a direct trade-off between impact force and surface area. Larger balls provide greater impact, which is necessary for breaking down large, coarse feed particles. Smaller balls create a much larger total surface area, which is more efficient for the fine grinding of smaller particles.

Media Type: Density and Wear Resistance

The material of the media matters significantly. Steel balls are dense and provide high-impact force, ideal for tough materials. Ceramic balls are used when product contamination from steel is a concern. The choice depends on the required grinding energy and purity standards.

The Filling Ratio (Ball Charge)

The filling ratio, or ball charge, is the percentage of the mill's internal volume occupied by the media. A typical charge is between 30% and 45%. Too low a charge results in wasted energy and inefficient grinding, while too high a charge can restrict the movement of both the media and the material being ground.

Material Characteristics Matter

The final set of variables relates to the material you are processing. The mill's configuration must be adapted to the specific properties of the feed material.

Feed Size and Hardness

Harder materials or larger feed particles require more impact energy to break. This may necessitate the use of larger, denser grinding media, a higher ball charge, or a longer residence time within the mill to achieve the target particle size.

Understanding the Trade-offs

Optimizing a ball mill is a process of managing competing factors. Improving one metric can often come at the expense of another, and understanding these trade-offs is essential for effective operation.

Speed vs. Wear

Operating at higher speeds (within the optimal range) can increase throughput, but it also accelerates the wear rate of both the grinding media and the mill's internal lining. This increases operational costs and maintenance frequency.

Throughput vs. Final Particle Size

Pushing material through the mill faster will increase your output tonnage, but it reduces the residence time. This typically results in a coarser final product. Achieving a very fine grind almost always requires a lower throughput rate.

Optimizing Performance for Your Goal

Your ideal setup depends entirely on what you are trying to achieve. There is no single "best" configuration; there is only the best configuration for your specific application.

- If your primary focus is breaking down coarse, hard materials: Use larger, high-density media (like steel) and operate toward the higher end of the optimal speed range (around 75% of critical speed).

- If your primary focus is achieving the finest possible particle size: Use smaller grinding media to maximize surface area and consider a slightly lower ball charge (around 30-35%) to promote fine grinding over high impact.

- If your primary focus is maximizing energy efficiency: Carefully balance the ball charge and mill speed to ensure every rotation is performing useful work, avoiding the inefficient conditions of sliding or centrifuging.

Mastering these variables transforms ball milling from a simple crushing process into a precise and controllable engineering discipline.

Summary Table:

| Factor | Key Influence | Typical Optimal Range |

|---|---|---|

| Mill Speed | Controls grinding action (cascading vs. centrifuging) | 65% - 75% of critical speed |

| Media Size | Balances impact force (large balls) vs. surface area (small balls) | Depends on feed particle size |

| Media Type | Determines grinding energy and product contamination risk | Steel (high impact) or Ceramic (high purity) |

| Filling Ratio | Percentage of mill volume occupied by grinding media | 30% - 45% |

| Feed Material | Hardness and initial size dictate required energy and residence time | Configuration must be adapted |

Ready to optimize your ball milling process for maximum efficiency and precise particle size control?

The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing tailored solutions for your specific grinding challenges. Contact us today to discuss how we can enhance your laboratory's performance and achieve your processing goals.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity