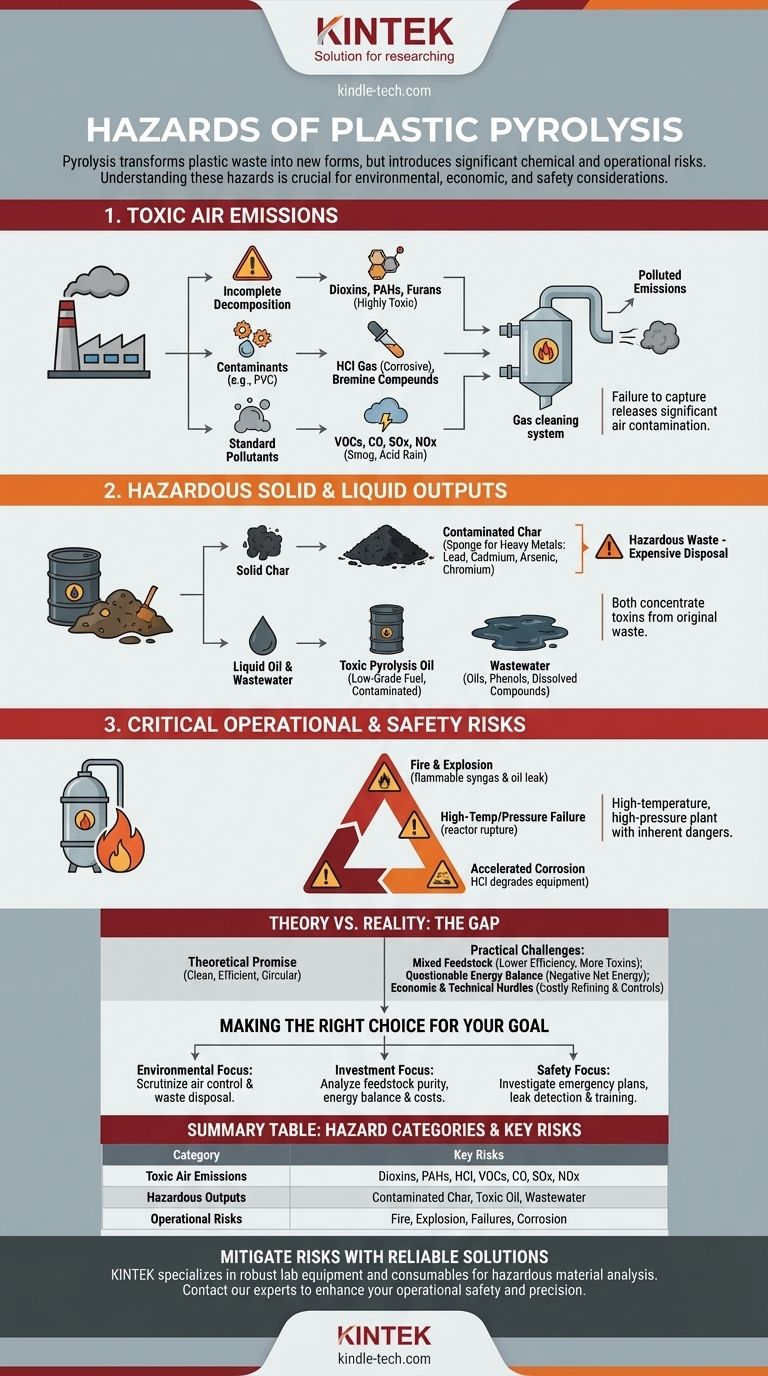

The primary hazards of plastic pyrolysis are the generation of toxic air emissions, the production of contaminated solid and liquid byproducts, and significant operational risks including fire and explosion. These dangers arise from the thermal decomposition of complex, often contaminated plastic waste streams in a low-oxygen environment, creating a new set of environmental and safety challenges that must be rigorously managed.

While often presented as a perfect circular solution for plastic waste, pyrolysis is an industrial chemical process with inherent hazards. The core challenge is that it doesn't eliminate pollutants but transforms them into different forms—air emissions, hazardous char, and contaminated oils—that require sophisticated and costly controls to prevent harm.

The Three Categories of Pyrolysis Hazards

Understanding the risks of pyrolysis requires breaking them down into three distinct areas: what is released into the air, what solid and liquid waste is left behind, and what can go wrong during the industrial process itself.

1. Toxic Air Emissions

The gas stream produced during pyrolysis is complex and requires extensive cleaning before it can be used as fuel or released. Failure to capture these pollutants results in significant air contamination.

Incomplete Decomposition Byproducts

Pyrolysis is decomposition without enough oxygen for full combustion. This process can create highly toxic and carcinogenic compounds, including dioxins, furans, and Polycyclic Aromatic Hydrocarbons (PAHs), which can be released if the gas cleanup systems are inadequate or fail.

Contaminants from Plastic Composition

Plastics are not pure hydrocarbons. Additives and different polymer types introduce other elements that become hazardous when heated. For example, Polyvinyl Chloride (PVC) releases large amounts of highly corrosive hydrochloric acid (HCl) gas, while flame retardants found in electronics can release bromine compounds.

Standard Gaseous Pollutants

Like other thermal processes, pyrolysis can emit Volatile Organic Compounds (VOCs), carbon monoxide (CO), and oxides of sulfur (SOx) and nitrogen (NOx). These are well-known air pollutants that contribute to smog, acid rain, and respiratory problems.

2. Hazardous Solid and Liquid Outputs

Pyrolysis does not make plastic vanish; it converts it into gas, liquid oil, and a solid char. Both the liquid and solid outputs concentrate hazardous substances from the original waste.

Contaminated Pyrolysis Char

The solid, carbon-rich residue left after pyrolysis is called char. This material acts like a sponge for heavy metals (such as lead, cadmium, arsenic, and chromium), which are often present as pigments, stabilizers, or contaminants in the plastic feedstock. This concentrates the toxins, often rendering the char a hazardous waste that requires careful and expensive disposal in specialized landfills.

Toxic Pyrolysis Oil and Wastewater

The liquid oil produced is a low-grade fuel that also contains many of the contaminants from the original plastic. Furthermore, water used to cool or "quench" the process becomes heavily contaminated with oils, phenols, and other dissolved organic compounds, creating a toxic wastewater stream that requires extensive treatment before it can be discharged.

3. Critical Operational and Safety Risks

A pyrolysis facility is a high-temperature, high-pressure chemical plant with inherent industrial dangers.

Fire and Explosion Potential

The primary products of pyrolysis—syngas and pyrolysis oil—are highly flammable. Any leak in the system can create a combustible atmosphere, leading to a high risk of fire or, under the right conditions, a powerful explosion.

High-Temperature and Pressure Failures

Pyrolysis reactors operate at extremely high temperatures (300-900°C). A failure of the reactor vessel, piping, or seals due to thermal stress or pressure buildup can lead to a catastrophic release of hot, flammable, and toxic materials.

Accelerated Corrosion

The presence of hydrochloric acid (from PVC) and other corrosive compounds in the gas stream can rapidly degrade steel reactors and piping. This corrosion weakens the equipment, increasing the likelihood of leaks and system failures over time.

Understanding the Trade-offs: Theory vs. Reality

The theoretical promise of pyrolysis often clashes with the practical realities of processing real-world waste, creating a gap between ideal outcomes and actual performance.

The Problem of Mixed, Contaminated Feedstock

In a laboratory, pyrolysis of pure, clean plastic can be a relatively clean process. However, real-world municipal plastic waste is a messy, commingled mix of different polymer types, labels, food residue, dirt, and non-plastic contaminants. This "dirty" feedstock makes the process far less efficient and generates a much higher load of toxic byproducts.

The Questionable Energy Balance

Pyrolysis is an energy-intensive process that requires significant external power to reach and maintain its high operating temperatures. For many real-world facilities, the energy consumed to run the plant and process the waste can be greater than the energy value of the fuel it produces, resulting in a negative net energy balance.

The Economic and Technical Hurdles

The low quality of the resulting pyrolysis oil means it requires extensive, costly refining before it can be used as a high-value fuel or chemical feedstock. When combined with the high costs of air pollution control, hazardous waste disposal, and facility maintenance (especially due to corrosion), the economic viability of many pyrolysis projects is highly challenging.

Making the Right Choice for Your Goal

Evaluating a pyrolysis project requires a clear-eyed assessment of how these significant hazards are identified, mitigated, and managed. Your focus should shift based on your primary objective.

- If your primary focus is environmental impact: Scrutinize the design of the air pollution control system, the plan for testing and disposing of the char, and the wastewater treatment process.

- If your primary focus is investment or economic viability: Demand a rigorous analysis of the feedstock purity requirements, the net energy balance, and the true operational costs, including hazardous waste disposal and ongoing maintenance.

- If your primary focus is community safety: Investigate the facility’s emergency response plans, process safety management program, leak detection systems, and operator training protocols.

A thorough understanding of these hazards is the essential first step toward making a truly informed decision about the role of pyrolysis in our waste management future.

Summary Table:

| Hazard Category | Key Risks |

|---|---|

| Toxic Air Emissions | Dioxins, PAHs, HCl gas, VOCs, CO, SOx, NOx |

| Hazardous Outputs | Char contaminated with heavy metals, toxic pyrolysis oil, wastewater |

| Operational Risks | Fire, explosion, high-temperature/pressure failures, accelerated corrosion |

Navigating complex chemical processes like pyrolysis requires reliable, high-quality equipment and expert support. KINTEK specializes in providing robust lab equipment and consumables for analyzing and managing hazardous materials. Whether you are testing feedstock, monitoring emissions, or ensuring process safety, our solutions are designed for precision and durability. Let us help you mitigate risks and enhance your operational safety. Contact our experts today to discuss your specific laboratory needs and how we can support your projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- How much CO2 is released from calcination? The Inescapable 44% Mass Loss from Limestone

- What is the microwave pyrolysis process? A Faster, More Efficient Waste-to-Value Solution

- Why are there chains inside a rotary kiln? Boost Efficiency & Control with Internal Heat Exchange

- What does calcination do? Purify and Transform Materials with Controlled Heat

- What are the disadvantages of fluidized beds? Understanding the Trade-offs of High-Performance Reactors

- What is the residence time of pyrolysis? A Key Control Parameter for Bio-oil, Biochar, and Syngas

- What are the principles of a rotary kiln? Master the Mechanics of High-Temperature Processing

- What furnace is used for calcination? A Guide to Muffle, Rotary Kiln, and Shaft Furnaces