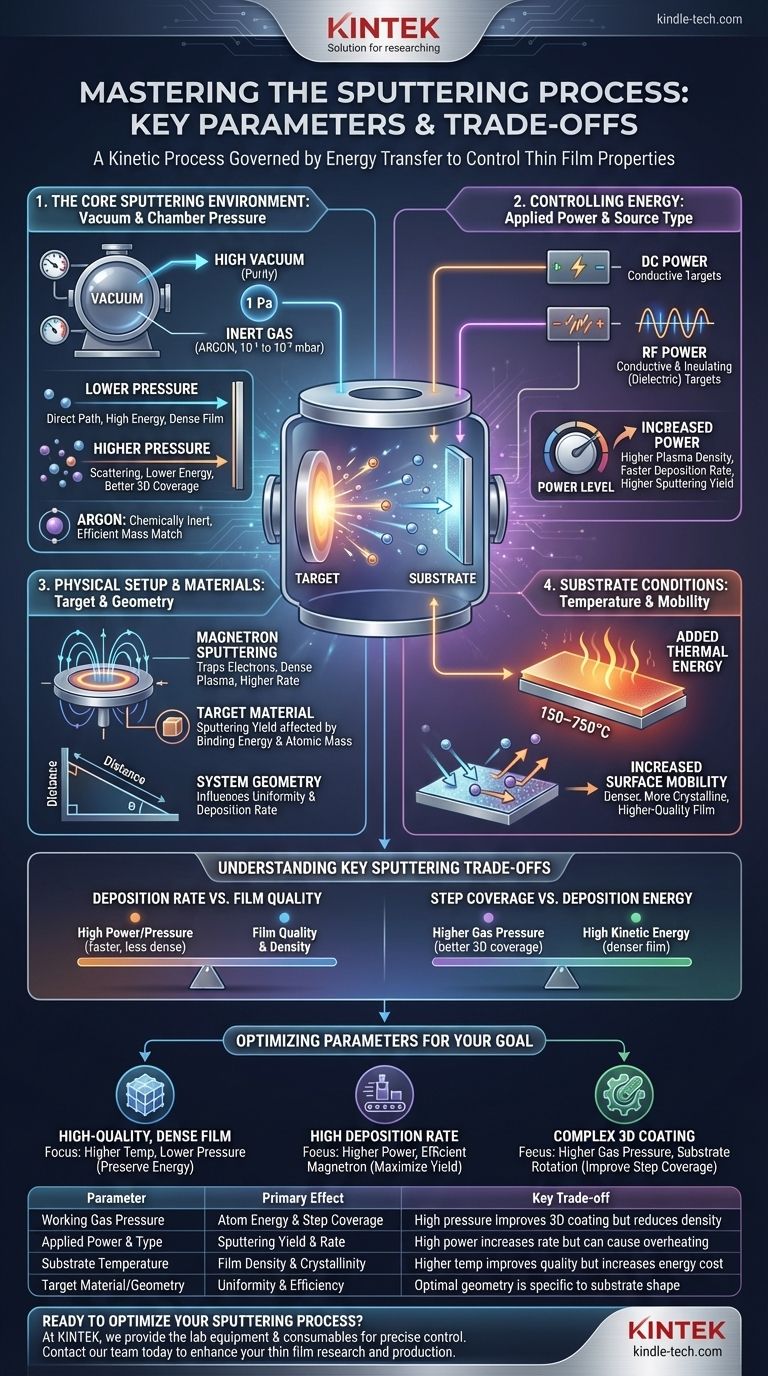

To control the sputtering process, you must manage four primary parameters: the working gas pressure within the vacuum chamber, the type and magnitude of the power applied to the target, the temperature of the substrate, and the physical characteristics of the system, such as the target material and its geometry relative to the substrate. These factors are not independent; they work together to define the energy of the sputtering ions and the journey of the sputtered atoms, ultimately determining the final properties of the deposited thin film.

Sputtering is a kinetic process governed by energy transfer. The core challenge is not just choosing the right parameters, but understanding how they interact to control the energy of particles at two key stages: the energy used to eject atoms from the target and the energy those atoms have when they arrive at the substrate.

The Core Sputtering Environment

The quality of any sputtered film begins with the environment in which it is created. The vacuum chamber and the gas within it are the foundational elements you must control.

The Role of Vacuum and Chamber Pressure

The process starts by pumping the chamber down to a high vacuum (e.g., around 1 Pa or lower) to remove contaminants like water vapor and residual air. This ensures the purity of the final film.

An inert working gas, typically Argon, is then introduced at a controlled low pressure (e.g., 10⁻¹ to 10⁻³ mbar). This pressure is a critical lever.

- Lower pressure results in fewer collisions between sputtered atoms and gas atoms. This creates a more direct, line-of-sight path to the substrate, preserving the high kinetic energy of the sputtered atoms, which can lead to a denser film.

- Higher pressure increases the number of collisions. This scattering effect can improve the film's coverage over complex, non-flat substrate topographies but reduces the energy of the atoms arriving at the substrate.

Choosing the Working Gas

Argon is the most common choice because it is chemically inert and has a suitable atomic mass for efficiently sputtering most materials.

The mass of the gas ion relative to the target atom influences the sputtering yield—the number of target atoms ejected per incoming ion. A better mass match can improve the efficiency of this energy transfer.

Controlling the Energy of the System

The energy applied to the system dictates both the speed of the process and the quality of the resulting film.

Applied Power and Source Type

Power is applied to ionize the working gas and create the plasma. The two main types are Direct Current (DC) and Radio Frequency (RF).

- DC Sputtering is highly effective for conductive target materials.

- RF Sputtering is more versatile, as it can be used for both conductive and electrically insulating (dielectric) materials. It works by alternating the electric field, preventing charge from building up on the insulator's surface, which would otherwise halt the process.

Increasing the power generally increases the plasma density and ion energy, leading to a higher sputtering yield and a faster deposition rate.

The Impact of Substrate Temperature

Heating the substrate, often to temperatures between 150–750°C, is another way to inject energy into the process.

This added thermal energy gives the newly deposited atoms more surface mobility. It allows them to move around on the substrate surface to find more stable, lower-energy positions within the film's crystal lattice, resulting in a denser, more crystalline, and higher-quality film structure.

The Physical Setup and Materials

The fixed components of your sputtering system also act as critical process parameters.

Target Material and System Geometry

The sputtering yield is directly affected by the binding energy and atomic mass of the target material. Heavier atoms with weaker bonds are generally easier to sputter.

The distance and angle between the target and the substrate also play a significant role. This geometry determines the uniformity of the film across the substrate and influences the deposition rate at any given point.

The Function of Magnetic Fields

Modern systems almost always use magnetron sputtering. A magnetic field is applied near the target to trap free electrons in its vicinity.

This confinement dramatically increases the probability that electrons will collide with and ionize the argon gas atoms. The result is a much denser plasma concentrated near the target, leading to a significantly higher sputtering rate at lower gas pressures.

Understanding Key Sputtering Trade-offs

Optimizing the sputtering process is a balancing act. Improving one characteristic often comes at the expense of another.

Deposition Rate vs. Film Quality

Pushing for a high deposition rate by increasing power or pressure can be counterproductive. High power can generate excessive heat, while high pressure can lead to more gas incorporation and a more porous film structure, reducing overall quality and density.

Step Coverage vs. Deposition Energy

If you need to coat a complex 3D surface, a higher working gas pressure is beneficial because it scatters the sputtered atoms, allowing them to coat sidewalls. However, this same scattering effect reduces the kinetic energy of the atoms as they land, which can result in a less dense film.

Process Time vs. System Cost

The total cycle time is heavily influenced by the chamber size and the capability of its vacuum pumping system. A larger chamber can process more substrates at once but takes longer to pump down to the required vacuum, creating a trade-off between throughput and initial setup time.

Optimizing Parameters for Your Goal

Your choice of parameters should be driven by the desired outcome for your thin film.

- If your primary focus is a high-quality, dense film: Prioritize parameters that increase atom mobility on the substrate, such as a higher substrate temperature and a lower working gas pressure to preserve kinetic energy.

- If your primary focus is a high deposition rate: Use higher power settings and ensure your magnetron design is efficiently confining the plasma to maximize the sputtering yield.

- If your primary focus is coating a complex 3D shape: Utilize a higher working gas pressure to encourage atomic scattering and improve step coverage, potentially combined with substrate rotation.

Mastering the sputtering process is about understanding how these interconnected variables control the flow of energy and matter from the target to the substrate.

Summary Table:

| Parameter | Primary Effect on Process | Key Trade-off |

|---|---|---|

| Working Gas Pressure | Controls atom energy & step coverage | High pressure improves 3D coating but reduces film density |

| Applied Power & Type | Determines sputtering yield & rate | High power increases rate but can cause overheating |

| Substrate Temperature | Influences film density & crystallinity | Higher temp improves quality but increases energy cost |

| Target Material/Geometry | Affects deposition uniformity & efficiency | Optimal geometry is specific to the substrate shape |

Ready to optimize your sputtering process for superior thin films?

At KINTEK, we specialize in providing the lab equipment and consumables you need to precisely control these critical parameters. Whether your goal is maximum film density, high deposition rates, or perfect coverage on complex 3D structures, our experts can help you select the right sputtering solutions for your laboratory's unique challenges.

Contact our team today to discuss how we can enhance your thin film research and production.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods