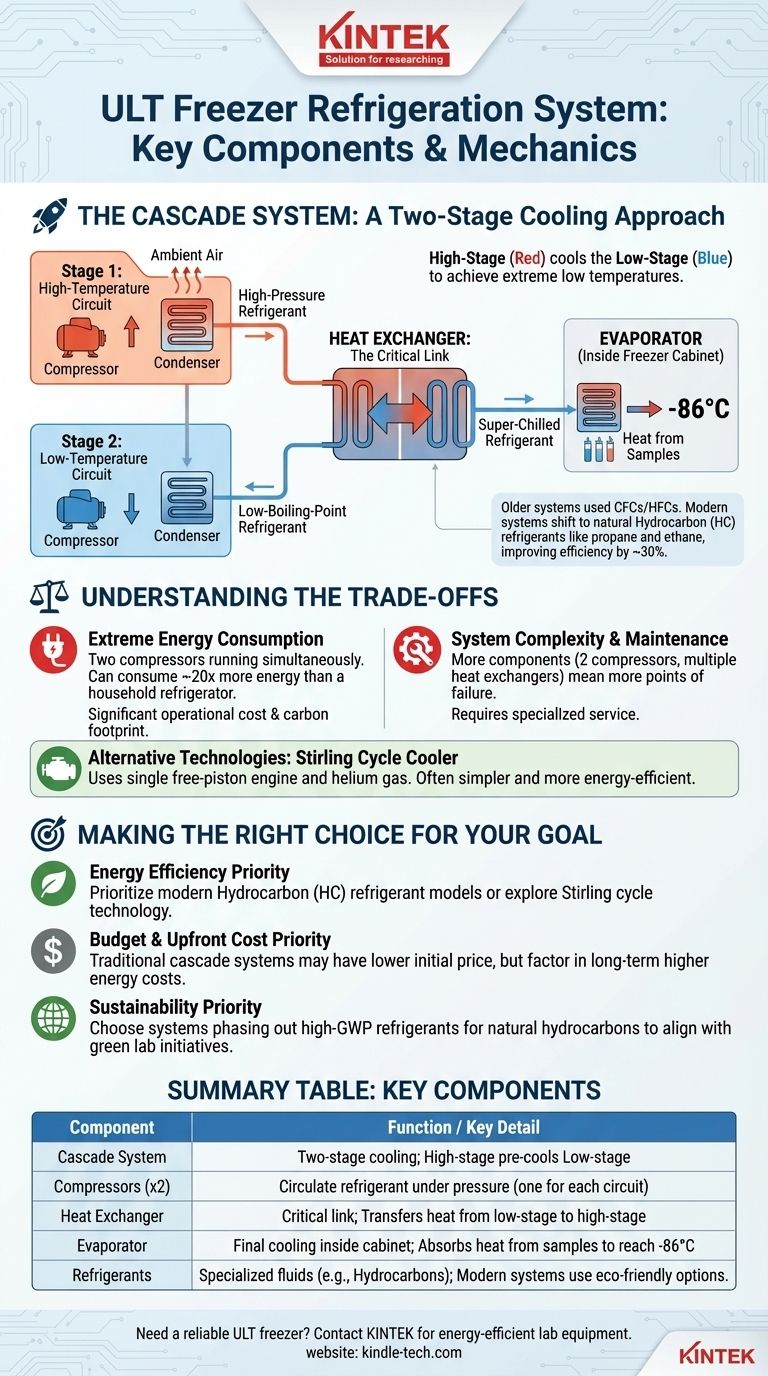

At its core, a modern Ultra-Low Temperature (ULT) freezer uses a sophisticated, multi-stage refrigeration system to achieve temperatures as low as -86°C. The key components that enable this are compressors, condensers, heat exchangers, evaporators, and specialized refrigerants working in a configuration known as a cascade system. This design is far more complex and powerful than that of a standard household refrigerator.

A ULT freezer's refrigeration system is best understood not as a single unit, but as two interconnected cooling circuits working in sequence. The first circuit cools the second, allowing the second circuit to reach the extreme temperatures required for long-term sample preservation.

The Cascade System: A Two-Stage Approach

Most ULT freezers operate on a cascade refrigeration system. Think of it as a two-stage rocket; the first stage lifts the second one high enough so it can reach its final destination. In a freezer, the first refrigeration circuit's only job is to get cold enough to cool down the second circuit.

The High-Temperature Circuit (Stage 1)

The high-temperature (or "high-stage") circuit functions much like a standard freezer. A compressor circulates a high-pressure refrigerant, which releases heat to the ambient air as it passes through a condenser. This cooled liquid refrigerant then absorbs heat from the second stage, pre-cooling it for its own cycle.

The Low-Temperature Circuit (Stage 2)

This is where the ultra-low temperatures are generated. The low-temperature circuit uses its own compressor and a special low-boiling-point refrigerant. Its "condenser" doesn't release heat into the room; instead, it releases heat into the evaporator of the first circuit. This super-chilled refrigerant then flows to the final evaporator inside the freezer cabinet, absorbing heat from your samples and pulling the chamber down to -86°C.

Heat Exchangers: The Critical Link

A heat exchanger is the physical component where the two circuits meet. It is where the evaporator of the high-stage circuit makes contact with the condenser of the low-stage circuit. Efficient heat transfer at this point is absolutely critical for the entire system to function and reach its target temperature.

Refrigerants: The Shift to Efficiency

The fluids circulating within these circuits are specialized refrigerants. Older systems relied on chlorofluorocarbons (CFCs) or hydrofluorocarbons (HFCs), which have a high global warming potential. Modern ULT freezers have largely shifted to natural hydrocarbon (HC) refrigerants, such as propane and ethane. These HC systems can improve energy efficiency by up to 30% and have a significantly lower environmental impact.

Understanding the Trade-offs

The cascade design is incredibly effective at producing cold, but this performance comes with clear trade-offs that every lab manager should understand.

Extreme Energy Consumption

The primary drawback is energy usage. Running two independent compressor systems simultaneously is highly energy-intensive. A cascade ULT freezer can consume nearly 20 times more energy than a typical household refrigerator, making it a significant contributor to a lab's operational costs and carbon footprint.

System Complexity and Maintenance

With two compressors, two sets of refrigerants, and multiple heat exchangers, a cascade system is inherently more complex than a single-compressor design. This complexity can lead to more potential points of failure and may require more specialized service and maintenance over the freezer's lifespan.

The Rise of Alternative Technologies

To address the energy and complexity issues, some manufacturers offer alternative cooling technologies. The most prominent is the Stirling cycle cooler, which uses a single free-piston engine and helium gas as a refrigerant. These systems are often simpler and more energy-efficient, representing a different approach to the same engineering challenge.

Making the Right Choice for Your Goal

Understanding these components helps you move beyond marketing and select a freezer based on your lab's specific priorities.

- If your primary focus is energy efficiency: Prioritize models that use modern hydrocarbon (HC) refrigerants or investigate alternative technologies like Stirling cycle freezers.

- If your primary focus is budget and upfront cost: A traditional cascade system may have a lower initial purchase price, but be sure to factor in its higher long-term energy costs.

- If your primary focus is sustainability: Choose systems that have phased out high-GWP refrigerants in favor of natural hydrocarbons to align with institutional green lab initiatives.

By understanding the technology inside the box, you can make a more informed and strategic decision for your lab's critical samples.

Summary Table:

| Component | Function | Key Detail |

|---|---|---|

| Cascade System | Two-stage cooling process | High-stage circuit pre-cools the low-stage circuit |

| Compressors (x2) | Circulate refrigerant under pressure | One for each independent circuit |

| Heat Exchanger | Critical link between the two circuits | Transfers heat from the low-stage to the high-stage |

| Evaporator | Final cooling component inside the cabinet | Absorbs heat from samples to reach -86°C |

| Refrigerants | Specialized fluids (e.g., Hydrocarbons) | Modern systems use eco-friendly, efficient options like propane/ethane |

Need a reliable Ultra-Low Temperature freezer for your lab's most critical samples?

Choosing the right ULT freezer is a major decision that impacts your sample integrity, operational costs, and sustainability goals. At KINTEK, we specialize in providing high-performance lab equipment, including energy-efficient ULT freezers that leverage modern hydrocarbon refrigerants and advanced cooling technologies.

Our experts can help you select the perfect model to meet your specific needs for temperature stability, energy savings, and long-term reliability.

Contact our lab equipment specialists today for a personalized consultation and discover how KINTEK can support your laboratory's success.

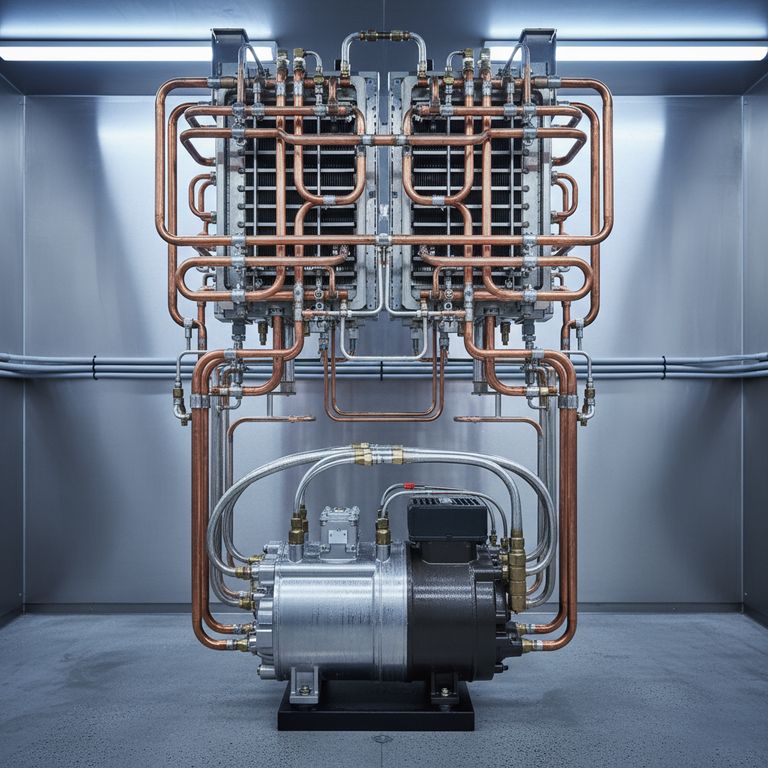

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples