At its core, a ball mill's primary components are the rotating cylindrical shell, the inner lining that protects it, the grinding media that performs the size reduction, and the drive system that powers the entire operation. These parts work in concert with the feed and discharge mechanisms to create a robust system for pulverizing materials.

A ball mill is more than a collection of parts; it is an engineered system where each component is precisely selected to control the forces of impact and attrition. Understanding how the shell, liners, media, and drive system interact is the key to achieving a specific particle size and operational efficiency.

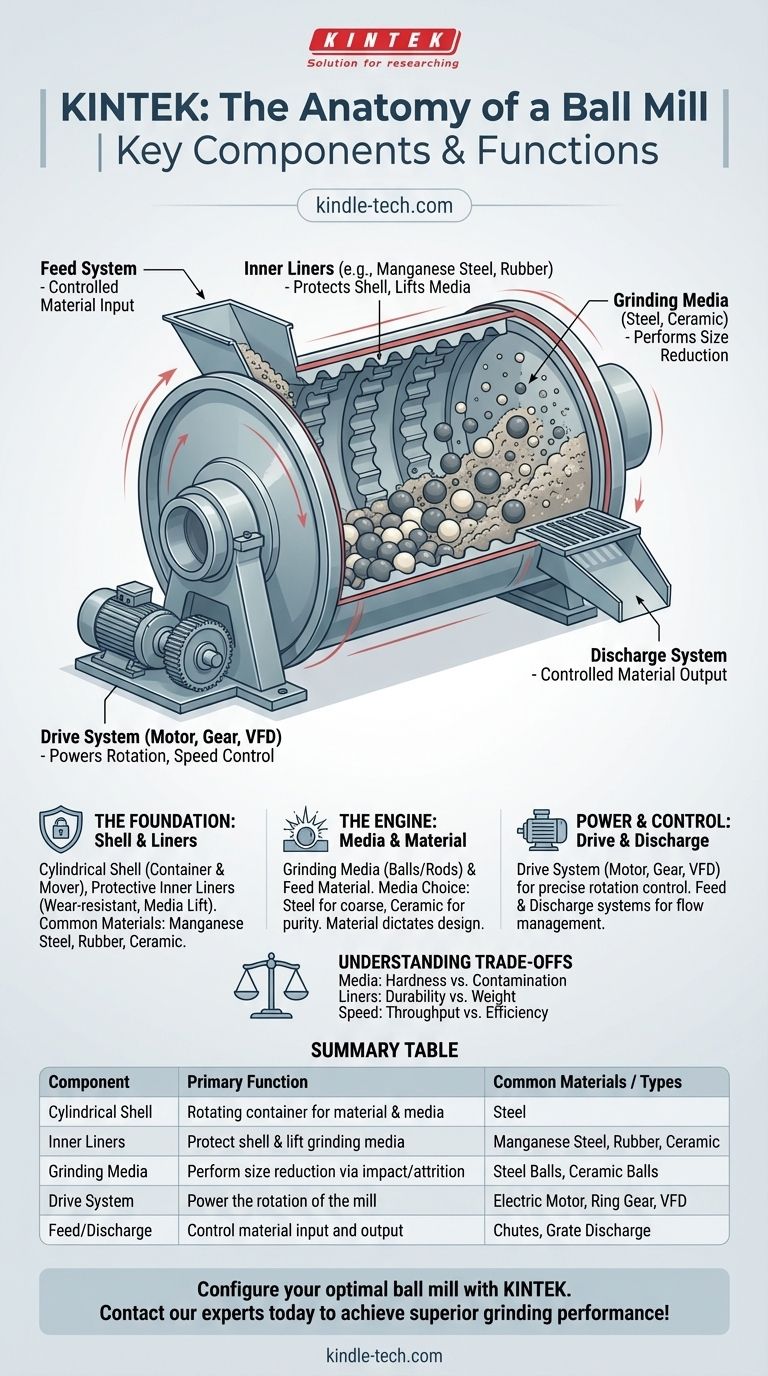

The Foundation: Shell and Liners

A ball mill's structure is its most visible feature, but its design is critical for durability and grinding performance. It serves as both the container and the primary mover of the grinding media.

The Cylindrical Shell

The shell is a hollow cylinder, typically made of steel, that rotates on its horizontal axis. It acts as the container for both the material being ground (the "charge") and the grinding media. Its structural integrity is paramount to the mill's safety and longevity.

The Protective Inner Liners

The inner surface of the shell is fitted with liners. These are sacrificial plates made from highly wear-resistant materials.

Liners serve two essential functions. First, they protect the shell from the intense abrasion and impact caused by the tumbling media and charge. Second, their shape (e.g., wave, step) helps lift the media as the mill rotates, which is crucial for creating the cascading, grinding action. Common materials include manganese steel for high-impact durability or rubber for specific applications.

The Engine of Grinding: Media and Material

The actual work of particle size reduction happens through the interaction between the grinding media and the material being processed.

The Grinding Media

This is the "engine" of the mill. It consists of balls (or sometimes rods or cylinders) that are free to move inside the shell. As the mill rotates, the media is lifted and then tumbles or cascades down, crushing and grinding the material through impact and attrition.

Media is chosen based on the application. Steel balls are dense and effective for coarse, hard materials. Ceramic balls are used when product purity is critical, as they prevent metallic contamination.

The Feed Material

While not a component of the mill itself, the material being fed into it dictates every other design choice. The material's hardness, initial particle size, and abrasiveness will determine the optimal type of liners, media, and rotational speed.

The Power and Control: Drive and Discharge Systems

A ball mill is an inert cylinder without the systems that power its rotation and manage the flow of material.

The Drive System

The drive system provides the rotational force. It typically consists of a powerful electric motor connected to a gear system (often a large ring gear on the shell itself) that turns the cylinder.

Modern drive systems often include a Variable Frequency Drive (VFD). This allows for precise control over the mill's rotational speed, which is a critical parameter for optimizing grinding efficiency.

The Feed and Discharge Systems

Material must be able to enter and exit the mill in a controlled manner. The feed system is an opening or chute, often at the center of one end of the mill, where raw material is introduced.

The discharge system allows the ground material to exit. In many designs, this is a grate at the opposite end that allows particles below a certain size to pass through while retaining the larger grinding media.

Understanding the Trade-offs

Selecting the right components involves balancing performance, cost, and operational goals. There is no single "best" configuration.

Media Selection: Hardness vs. Contamination

Hard, dense steel media provides the most powerful grinding action but can chip and introduce iron contamination into the final product. Softer, less-dense ceramic media avoids this but may not be effective on very hard materials and can be more costly.

Liner Choice: Durability vs. Weight

Manganese steel liners are exceptionally durable against both impact and abrasion, but they are heavy, which increases the energy required to rotate the mill. Rubber liners are lighter and can reduce noise but may wear faster with sharp, abrasive materials.

Speed Control: Throughput vs. Efficiency

Running a mill at a higher speed can increase throughput, but only up to a point. If the speed is too high (approaching "critical speed"), the media will be held against the shell by centrifugal force, and no grinding will occur. Finding the optimal speed is a key trade-off between production rate and energy consumption.

Making the Right Choice for Your Goal

The ideal component setup depends entirely on what you need to achieve.

- If your primary focus is maximizing throughput for coarse materials: Opt for large-diameter, high-density steel media and durable manganese steel liners designed for maximum lift.

- If your primary focus is producing a fine powder with zero contamination: Use high-alumina ceramic media and consider rubber or ceramic liners to ensure product purity.

- If your primary focus is energy efficiency and process control: Invest in a system with a Variable Frequency Drive (VFD) to precisely tune the rotational speed for different materials and desired outcomes.

By understanding how each component contributes to the whole, you can configure a ball mill not just to run, but to perform precisely as your process requires.

Summary Table:

| Component | Primary Function | Common Materials / Types |

|---|---|---|

| Cylindrical Shell | Rotating container for material and media | Steel |

| Inner Liners | Protect shell & lift grinding media | Manganese Steel, Rubber, Ceramic |

| Grinding Media | Perform size reduction via impact/attrition | Steel Balls, Ceramic Balls |

| Drive System | Power the rotation of the mill | Electric Motor, Ring Gear, VFD |

| Feed/Discharge | Control material input and output | Chutes, Grate Discharge |

Ready to configure a ball mill that perfectly matches your material and output goals?

KINTEK specializes in laboratory equipment and consumables, providing expert guidance and robust ball mill solutions for your specific grinding needs. Whether you require high throughput, fine powder purity, or energy-efficient operation, our team can help you select the optimal components.

Contact our experts today to discuss your application and achieve superior grinding performance!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- Why are Zirconia (ZrO2) grinding balls used for Al2O3/ZrO2 powders? Ensure High Purity and Milling Efficiency

- Why is the material of the mortar critical for Yttria-stabilized Ceria powder? Ensure Purity with Agate or Zirconia

- Why is a laboratory ball mill required for ultra-fine fly ash? Unlock Nano-Scale Adsorption Power

- What is the effect of speed of rotation on size reduction mechanism involved in ball mill? Optimize Your Grinding Efficiency

- What types of gases, other than standard compressed air, can be used in jet milling? Enhance Precision and Safety

- What function does a laboratory vibratory mill serve? Achieve 1–5 µm Precision for Cs-Aluminosilicate Powder

- Why are zirconia grinding beads utilized for LLZTO solid-state electrolytes? Ensuring Purity & High Ionic Conductivity

- What are the different types of pellet mills? Choose the Right Mill for Your Production Scale