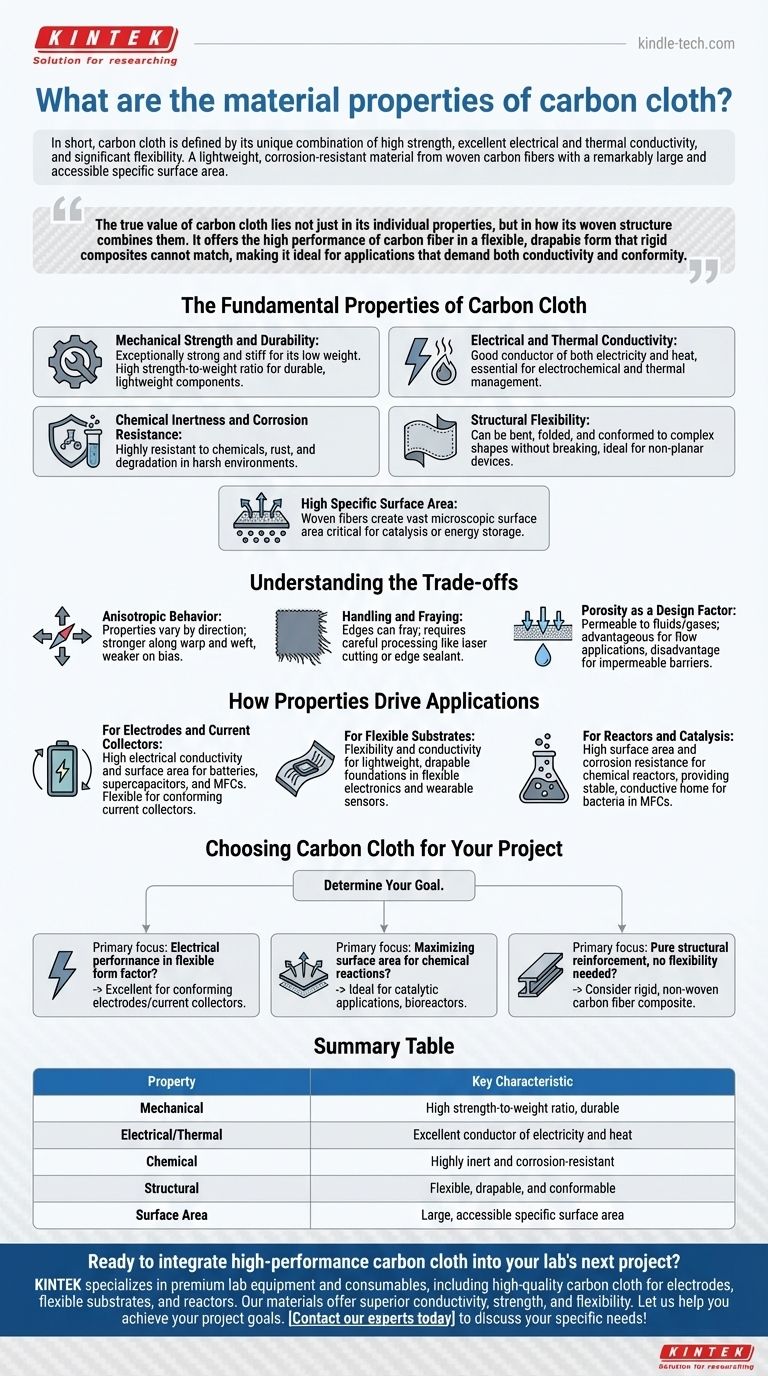

In short, carbon cloth is defined by its unique combination of high strength, excellent electrical and thermal conductivity, and significant flexibility. It is a lightweight, corrosion-resistant material manufactured by weaving carbon fibers together, a process that gives the cloth a remarkably large and accessible specific surface area.

The true value of carbon cloth lies not just in its individual properties, but in how its woven structure combines them. It offers the high performance of carbon fiber in a flexible, drapable form that rigid composites cannot match, making it ideal for applications that demand both conductivity and conformity.

The Fundamental Properties of Carbon Cloth

Carbon cloth inherits the core characteristics of the carbon fibers from which it is made, but its woven textile form introduces new, critical advantages.

Mechanical Strength and Durability

Carbon cloth is exceptionally strong and stiff for its low weight. This high strength-to-weight ratio makes it a valuable material for creating durable, lightweight components that can withstand significant physical stress.

Electrical and Thermal Conductivity

As a material made from pure carbon, the cloth is a good conductor of both electricity and heat. This property is essential for its use in electrochemical applications where it must efficiently transfer electrical charge or dissipate thermal energy.

Chemical Inertness and Corrosion Resistance

Carbon cloth is highly resistant to corrosion and degradation from a wide range of chemicals. It does not rust or react in many harsh environments, ensuring long-term stability and performance, particularly in fuel cells or battery systems.

Structural Flexibility

This is a key differentiator. Unlike rigid carbon fiber plates or composites, the woven nature of carbon cloth allows it to be bent, folded, and conformed to complex shapes without breaking. This makes it an ideal substrate for non-planar devices.

High Specific Surface Area

The weave of individual carbon fibers creates a vast microscopic surface area relative to the material's overall volume and weight. This is critical for applications where surface reactions are paramount, as it provides more active sites for catalysis or energy storage.

Understanding the Trade-offs

No material is perfect. Acknowledging the inherent trade-offs of carbon cloth is essential for successful implementation.

Anisotropic Behavior

Because it is a woven material, its properties are anisotropic, meaning they are not the same in every direction. The cloth will typically be much stronger along the direction of the fibers (the warp and weft) than it is on the bias (at a 45-degree angle).

Handling and Fraying

Like any textile, the edges of carbon cloth can fray when cut or handled. This requires careful processing techniques, such as laser cutting or applying an edge sealant, to maintain its structural integrity during manufacturing.

Porosity as a Design Factor

The space between the woven fibers makes the cloth porous. While this is an advantage for applications needing fluid or gas flow (like in a fuel cell reactor), it is a disadvantage if you require a solid, impermeable barrier.

How Properties Drive Applications

The unique blend of properties in carbon cloth makes it the material of choice for several advanced technical applications.

For Electrodes and Current Collectors

The combination of high electrical conductivity and large surface area makes carbon cloth an excellent material for electrodes in batteries, supercapacitors, and microbial fuel cells (MFCs). Its flexibility also allows it to serve as a conforming current collector.

For Flexible Substrates

Its flexibility and conductivity allow it to act as a lightweight and drapable foundation for flexible electronics or wearable sensors, where rigid circuit boards are not feasible.

For Reactors and Catalysis

The high surface area and corrosion resistance are ideal for use in chemical reactors. In MFCs, for example, it provides a large, stable, and conductive home for bacteria to colonize and generate electricity.

Choosing Carbon Cloth for Your Project

Use this guide to determine if carbon cloth is the right fit for your specific goal.

- If your primary focus is electrical performance in a flexible form factor: Carbon cloth is an excellent choice for electrodes or current collectors that need to conform to a specific shape.

- If your primary focus is maximizing surface area for chemical reactions: Its woven structure makes it ideal for catalytic applications or as a substrate in microbial fuel cells and other bioreactors.

- If your primary focus is pure structural reinforcement without a need for flexibility: A rigid, non-woven carbon fiber composite might be a more suitable and cost-effective choice for your application.

Understanding these distinct properties is the first step toward leveraging carbon cloth effectively in your design.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Mechanical | High strength-to-weight ratio, durable |

| Electrical/Thermal | Excellent conductor of electricity and heat |

| Chemical | Highly inert and corrosion-resistant |

| Structural | Flexible, drapable, and conformable |

| Surface Area | Large, accessible specific surface area |

Ready to integrate high-performance carbon cloth into your lab's next project?

KINTEK specializes in providing premium lab equipment and consumables, including high-quality carbon cloth ideal for electrodes, flexible substrates, and reactor applications. Our materials offer the superior conductivity, strength, and flexibility your research demands.

Let us help you achieve your project goals. Contact our experts today to discuss your specific needs!

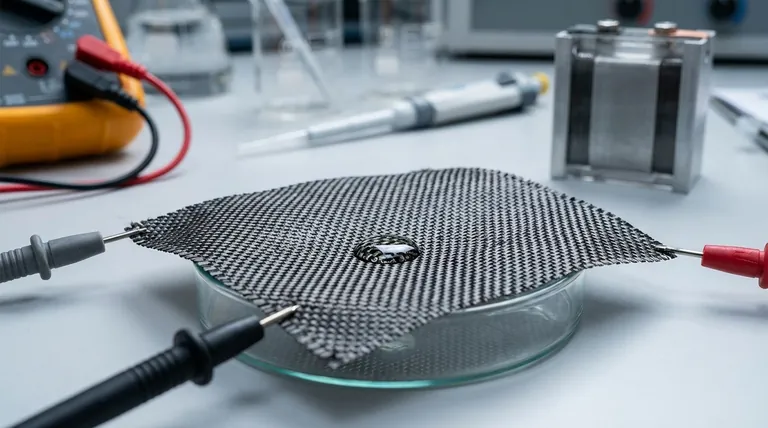

Visual Guide

Related Products

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

People Also Ask

- What are the requirements for heating equipment in large-scale Oxide Solid Electrolyte production? Scaling with Precision

- What is the function of a precision manual crimper? Ensure Perfect Seals for CR2032 Coin-Cell Assembly

- Why is a battery test fixture with pressure control functionality necessary for all-solid-state battery testing?

- What is the function of a vacuum drying oven in cathode film casting? Optimize Li-S Battery Manufacturing

- How to tell if a lithium-ion battery is bad? Spot the critical signs of failure before it's too late.

- Why is a laboratory hydraulic press essential for sulfide solid electrolyte layers? Optimize Your Battery Research

- What is the primary function of a vacuum drying oven in the pretreatment of PEO electrolytes? Achieve Battery Stability

- Why use zirconia grinding balls for sulfide electrolytes? Achieve High Purity in Solid-State Battery Research