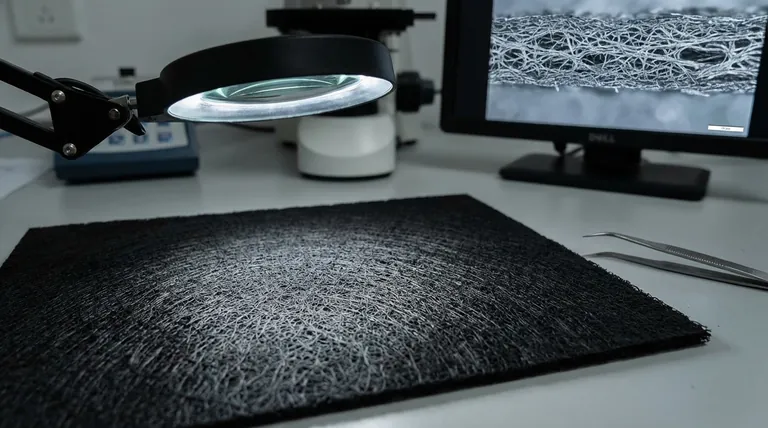

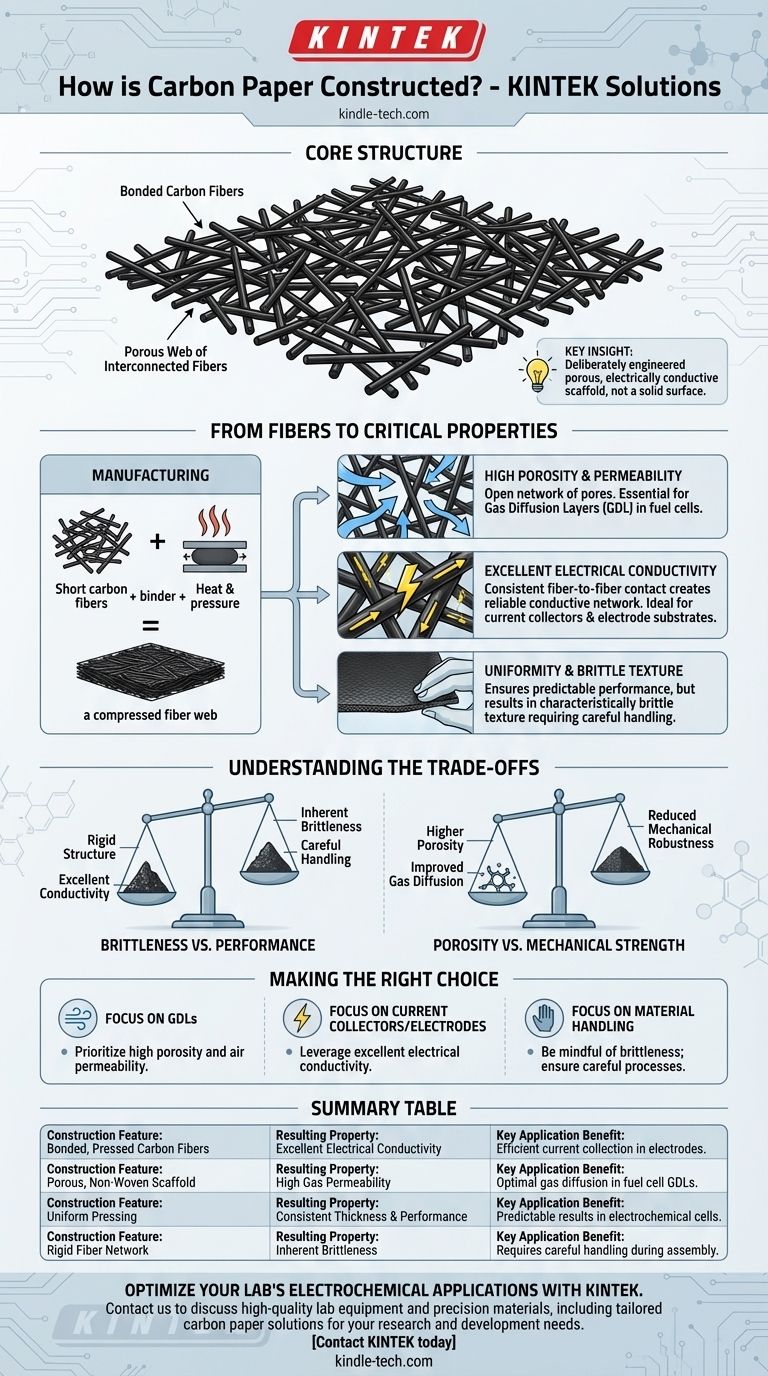

At its core, carbon paper is a non-woven material constructed from short carbon fibers that are bonded and pressed together to form a thin, sheet-like structure. This process is specifically designed to create a material that is not a solid surface, but rather a porous, electrically conductive scaffold.

The key insight is that carbon paper's construction is deliberately engineered to create a porous web of interconnected fibers. This unique structure is directly responsible for its high electrical conductivity and gas permeability, which are the very properties that make it invaluable in advanced technical applications.

How Construction Dictates Critical Properties

The manufacturing method directly gives rise to the material's defining characteristics. Understanding this link is crucial for its effective application.

The Foundation: Bonded Carbon Fibers

The process begins with short, chopped carbon fibers. These fibers are formed into a web, mixed with a binder, and then subjected to heat and pressure.

This compression forces the fibers into close contact, creating a continuous electrical pathway throughout the sheet while preserving a porous internal structure.

Result 1: High Porosity and Permeability

The gaps between the randomly oriented, bonded fibers create an open network of pores.

This high porosity allows gases and liquids to flow through the material with minimal resistance, a property essential for its role as a Gas Diffusion Layer (GDL) in fuel cells.

Result 2: Excellent Electrical Conductivity

Carbon itself is a conductive material. By pressing the fibers together, the manufacturing process ensures consistent fiber-to-fiber contact.

This creates a reliable conductive network across the entire sheet, making it an ideal material for current collectors and electrode substrates.

Result 3: Uniformity and Texture

The pressing stage ensures a highly uniform thickness across the sheet, which is critical for consistent and predictable performance in electrochemical cells.

However, the rigid nature of the bonded carbon fibers also results in a characteristically brittle texture, requiring careful handling.

Understanding the Trade-offs

No material is perfect. The very process that gives carbon paper its advantages also introduces practical limitations.

Brittleness vs. Performance

The rigid, bonded fiber structure that provides excellent conductivity and dimensional stability also makes the material inherently brittle.

This requires careful handling during assembly and can be a limiting factor in applications that involve flexing or high vibration.

Porosity vs. Mechanical Strength

There is a direct trade-off between porosity and strength. A higher degree of porosity, which improves gas diffusion, often comes at the cost of reduced mechanical robustness.

Manufacturers must carefully balance these parameters to meet the specifications for a given application.

Making the Right Choice for Your Application

Knowing how carbon paper is constructed allows you to leverage its properties effectively.

- If your primary focus is on Gas Diffusion Layers (GDLs): Prioritize the material's high porosity and air permeability, which are direct results of its engineered non-woven structure.

- If your primary focus is on Current Collectors or Electrodes: Leverage the excellent electrical conductivity created by the network of pressed, interconnected carbon fibers.

- If your primary focus is on material handling and assembly: Be mindful of its inherent brittleness and ensure your processes are designed to manage fragile sheets without causing fractures.

Understanding that carbon paper is an engineered porous scaffold, not just a simple sheet, is the key to unlocking its full potential in your work.

Summary Table:

| Construction Feature | Resulting Property | Key Application Benefit |

|---|---|---|

| Bonded, Pressed Carbon Fibers | Excellent Electrical Conductivity | Efficient current collection in electrodes |

| Porous, Non-Woven Scaffold | High Gas Permeability | Optimal gas diffusion in fuel cell GDLs |

| Uniform Pressing | Consistent Thickness & Performance | Predictable results in electrochemical cells |

| Rigid Fiber Network | Inherent Brittleness | Requires careful handling during assembly |

Optimize your lab's electrochemical applications with the right materials.

The construction of carbon paper is critical for performance in fuel cells, electrolyzers, and other advanced systems. KINTEK specializes in providing high-quality lab equipment and consumables, including precision materials like carbon paper, tailored to your laboratory's specific research and development needs.

Let our expertise enhance your efficiency and results. Contact KINTEK today to discuss how our solutions can support your projects with reliable performance and expert guidance.

Visual Guide

Related Products

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Electrolytic Electrochemical Cell for Coating Evaluation

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

People Also Ask

- What is an RVC glassy carbon sheet? A High-Performance Material for Demanding Applications

- How should carbon cloth and carbon paper be cleaned after use? Preserve Material Integrity with Proper Care

- What are the major components of biomass? Unlocking the Building Blocks of Renewable Energy

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- How is carbon paper treated for use in fuel cells? The Critical PTFE Coating for Peak Performance