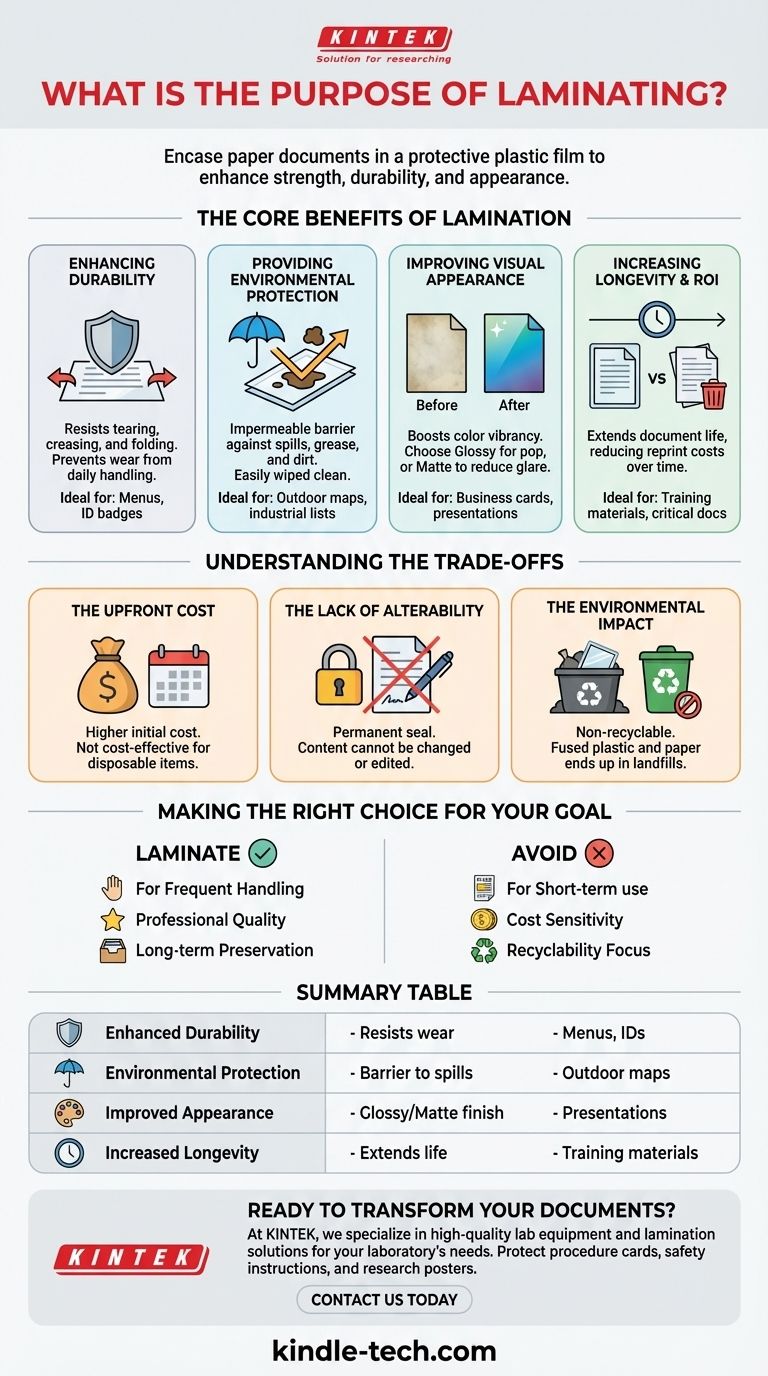

In essence, the purpose of lamination is to encase a paper document within a protective plastic film. This process fundamentally enhances the document's strength, durability, and appearance, safeguarding it from the rigors of frequent use and environmental damage.

Lamination is more than just a protective layer; it's a strategic decision to increase a document's lifespan and professional quality. Understanding its specific benefits and trade-offs is the key to determining if it’s a worthwhile investment for your materials.

The Core Benefits of Lamination

Laminating a document offers several distinct advantages that go beyond simple protection. These benefits address issues of durability, appearance, and long-term value.

Enhancing Durability and Strength

The plastic coating provides a rigid structure that makes paper highly resistant to tearing, creasing, and folding. It acts as a durable shield against the stress of daily handling.

This is why lamination is essential for items like restaurant menus or workshop instruction cards, which are handled by many people throughout the day.

Providing Environmental Protection

Lamination creates an impermeable barrier against spills, grease, fingerprints, and smudges. Most laminated documents can be easily wiped clean without damaging the paper inside.

This makes it ideal for maps used outdoors, price lists in industrial environments, or any document exposed to moisture or dirt.

Improving Visual Appearance

The lamination process can significantly improve a document's aesthetic quality. A glossy finish makes colors appear more vibrant and gives the item a striking, professional look.

Alternatively, a matte finish can reduce glare from lighting, which is useful for presentations or materials read under bright lights, while still providing a premium, tactile feel.

Increasing Longevity and ROI

While lamination adds an upfront cost, it drastically extends the life of a printed item. This reduces the need for constant reprints, offering a better return on investment over time.

A single set of laminated training materials can last for years, proving far more cost-effective than reprinting paper versions after every few sessions.

Understanding the Trade-offs

Lamination is a powerful tool, but it is not always the right solution. Objectively weighing its downsides is critical for making an informed choice.

The Upfront Cost

Lamination adds to the per-item production cost. For documents that are disposable or have a very short lifespan, this additional expense may not be justifiable.

The Lack of Alterability

Once a document is laminated, it cannot be changed. You cannot write on it (with standard pens), sign it, or alter the printed content in any way. This permanence is a significant drawback for documents requiring updates.

The Environmental Impact

Traditional plastic lamination makes paper non-recyclable. The fused plastic and paper are difficult to separate, meaning the final product will almost certainly end up in a landfill. For sustainability-focused projects, this is a major consideration.

Making the Right Choice for Your Goal

Deciding whether to laminate depends entirely on the intended use and desired outcome for your document.

- If your primary focus is frequent handling: Laminate to protect against wear, tear, and spills, making it perfect for menus, ID badges, or reusable checklists.

- If your primary focus is professional quality: Use lamination to give business cards, report covers, or sales presentations a premium finish that stands out.

- If your primary focus is long-term preservation: Laminate critical documents, maps, or educational materials that must withstand environmental factors and the test of time.

- If your primary focus is cost or recyclability: Avoid lamination for short-term flyers, temporary notices, or any document where the added expense and environmental impact are not justified.

Ultimately, lamination transforms a disposable document into a durable and reusable asset.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Enhanced Durability | Resists tearing, creasing, and folding | Menus, ID badges, workshop cards |

| Environmental Protection | Barrier against spills, moisture, and dirt | Outdoor maps, price lists, industrial documents |

| Improved Appearance | Glossy or matte finish for a professional look | Business cards, report covers, presentations |

| Increased Longevity | Extends document life, reducing reprint costs | Training materials, critical documents, educational resources |

Ready to transform your documents into durable, professional assets?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including reliable lamination solutions tailored to your laboratory's specific needs. Whether you need to protect important procedure cards, safety instructions, or research posters, our products ensure your materials withstand daily handling and environmental challenges.

Contact us today to discuss how our lamination supplies can enhance the durability and professionalism of your laboratory documents!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Lithium Battery Tab Tape for Battery Lab Applications

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- Nickel Aluminum Tabs for Soft Pack Lithium Batteries

- Aluminum Foil Current Collector for Lithium Battery

People Also Ask

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process