In short, carbon felt is primarily defined by its high porosity, large specific surface area, stable thermal and electrical conductivity, and low density. These characteristics stem from its unique internal construction, which is a three-dimensional, felt-like network of irregularly interwoven carbon fibers.

The true value of carbon felt isn't any single property, but the synergy of its features. Its porous, high-surface-area structure combined with its inherent conductivity makes it a uniquely effective material for facilitating reactions and managing heat in demanding applications.

The Foundational Properties of Carbon Felt

Carbon felt's utility is rooted in a few key physical and chemical characteristics. Understanding how these properties interact is crucial for its proper application.

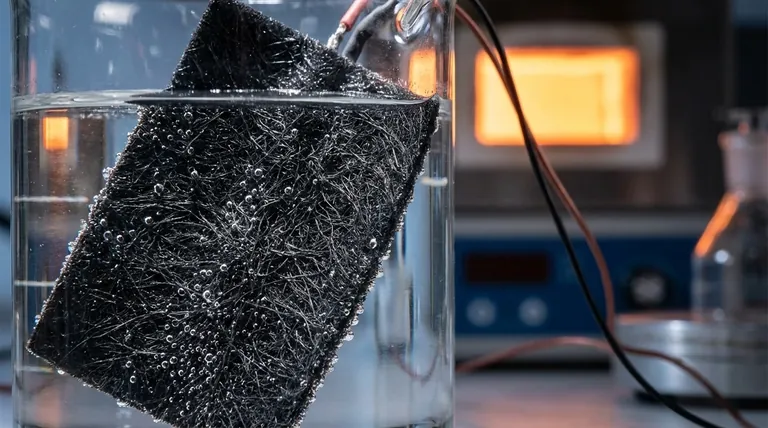

A Porous, 3D Structure

The material is not a solid block but a web of carbon fibers. This creates a highly porous, three-dimensional structure.

This porosity is essential as it allows liquids and gases, such as electrolytes or reactants, to flow through the material with minimal resistance.

High Specific Surface Area

A direct consequence of its porous, fibrous nature is an exceptionally high specific surface area.

This means there is a vast amount of exposed carbon surface within a small volume. This is critical for applications where surface reactions are important, as it provides more sites for chemical or electrochemical processes to occur.

Stable Electrical & Thermal Conductivity

Being made of carbon, the felt is a good conductor of both electricity and heat.

Crucially, this conductivity is stable even at high temperatures, making it a reliable material for furnace insulation or as an electrode in high-power systems.

Lightweight Nature

Carbon is an inherently low-density element. The porous structure of the felt further reduces its overall weight.

This makes it an excellent choice for applications where minimizing mass is a design goal, such as in aerospace components or portable energy devices.

Understanding the Practical Considerations

While powerful, carbon felt is not a universally perfect material. Its unique structure introduces specific challenges and limitations that you must manage for successful implementation.

The Challenge of Wetting

A common issue, particularly in electrochemical systems, is ensuring the felt is completely saturated with its liquid electrolyte. The material can trap air bubbles within its fibrous network.

These trapped bubbles are "dead zones" that are not electrochemically active, which significantly reduces the material's effective surface area and overall reaction efficiency.

Mechanical Integrity

The felt-like structure, while excellent for surface area and flow, is not designed for high mechanical stress.

Carbon felt can be compressed, and the individual fibers can be brittle. It should be used in applications where it is supported and not subjected to significant tensile or shear forces.

Making the Right Choice for Your Application

To apply this knowledge, match the material's dominant properties to your primary goal.

- If your primary focus is electrochemical performance (e.g., flow batteries, sensors): Prioritize its high surface area and porous structure to maximize reaction efficiency and ensure complete wetting.

- If your primary focus is high-temperature thermal management (e.g., furnace insulation): Leverage its stable thermal conductivity and low density for efficient and lightweight heat containment.

Understanding these core properties and their practical implications is the key to successfully leveraging carbon felt in your project.

Summary Table:

| Key Property | Description | Primary Benefit |

|---|---|---|

| High Porosity & 3D Structure | A web of interwoven carbon fibers creating open channels. | Allows easy flow of gases/liquids for efficient reactions. |

| Large Specific Surface Area | Vast amount of exposed carbon surface per unit volume. | Maximizes sites for chemical/electrochemical processes. |

| Stable Thermal & Electrical Conductivity | Maintains conductive properties even at high temperatures. | Reliable performance in furnaces and high-power systems. |

| Low Density & Lightweight | Inherently light carbon element with a porous structure. | Ideal for weight-sensitive applications like aerospace. |

Ready to leverage the unique properties of carbon felt in your lab?

KINTEK specializes in high-performance lab equipment and consumables. Whether you are developing advanced flow batteries, designing high-temperature furnaces, or creating sensitive sensors, our carbon felt products are engineered to deliver the porosity, surface area, and stable conductivity your application demands.

Let our experts help you select the right material to enhance your project's efficiency and reliability. Contact KINTEK today for a consultation and discover the difference quality materials make.

Visual Guide

Related Products

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Electrolytic Electrochemical Cell for Coating Evaluation

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- How should carbon cloth and carbon paper be cleaned after use? Preserve Material Integrity with Proper Care

- What is an RVC glassy carbon sheet? A High-Performance Material for Demanding Applications

- How is carbon paper constructed? The Engineered Porous Scaffold for High-Performance Applications

- What role does hydrophilic carbon fiber paper play as an electrode material? Enhancing Flow Cell Efficiency