When selecting an Ultra-Low Temperature (ULT) freezer, the most efficient and environmentally friendly options utilize natural hydrocarbon refrigerants. Specifically, modern systems often use a combination of R290 (Propane) and R170 (Ethane). These gases offer superior thermodynamic properties and have a negligible impact on global warming compared to the synthetic refrigerants they are replacing.

The core decision is no longer just about reaching a target temperature. It is a strategic choice to balance operational efficiency, long-term running costs, and environmental responsibility by opting for natural refrigerants with near-zero Global Warming Potential.

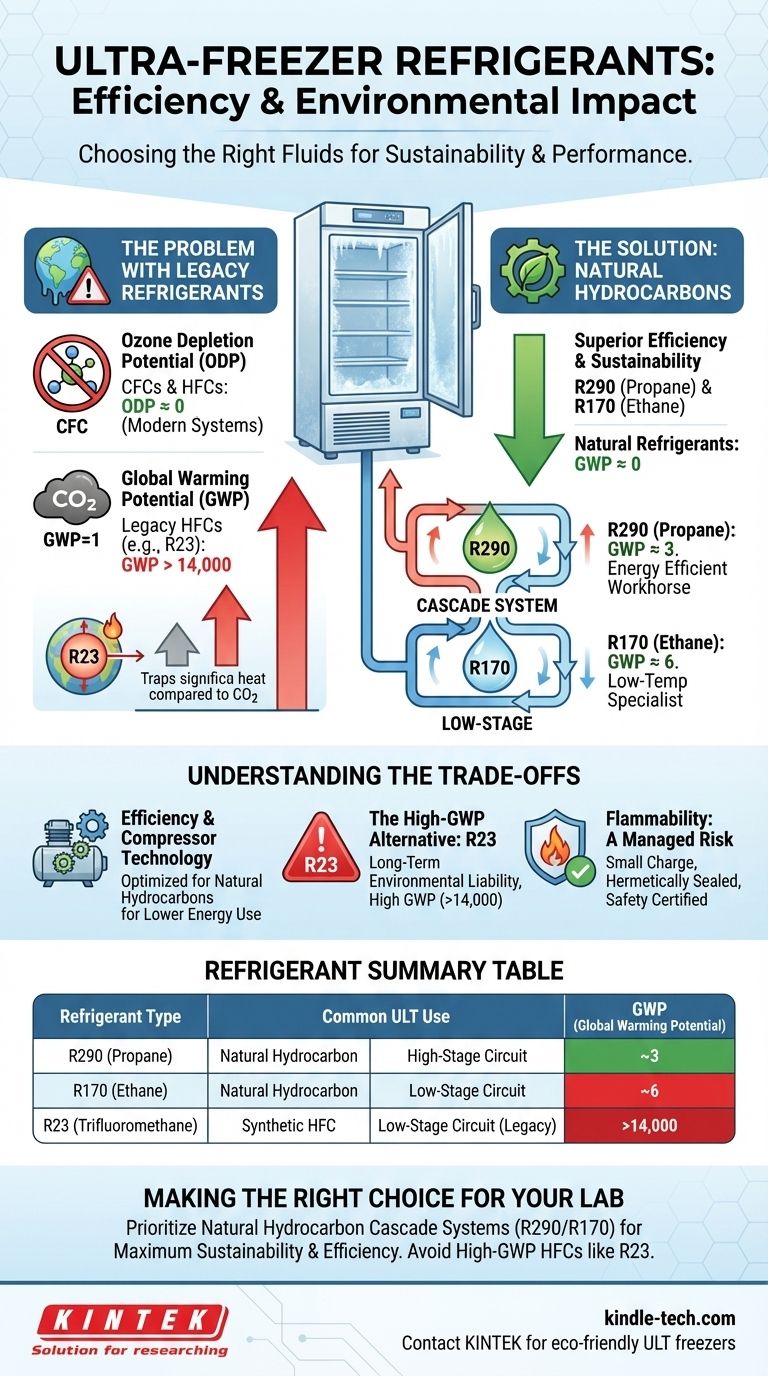

The Problem with Legacy Refrigerants

To understand the shift to natural refrigerants, it's essential to understand the issues with older chemical compounds used in refrigeration. The environmental impact of a refrigerant is measured by two key metrics.

Ozone Depletion Potential (ODP)

Older refrigerants like chlorofluorocarbons (CFCs) were found to damage the Earth's ozone layer. As a result, they were phased out under international agreements like the Montreal Protocol.

Modern refrigerants, including both synthetics (HFCs) and natural hydrocarbons, have an ODP of zero.

Global Warming Potential (GWP)

GWP measures a gas's ability to trap heat in the atmosphere compared to carbon dioxide (CO2), which has a GWP of 1.

Many first-generation CFC replacements, known as hydrofluorocarbons (HFCs), have an extremely high GWP. For example, R23, a common ULT refrigerant, has a GWP of over 14,000, meaning it traps 14,000 times more heat than CO2 over 100 years.

The Superiority of Natural Refrigerants

Modern ULT freezers achieve their low temperatures using a "cascade system," which is essentially two refrigeration systems working in tandem. This allows for the use of specialized refrigerants optimized for different temperature ranges.

R290 (Propane): The High-Stage Workhorse

In a cascade system, R290 is typically used in the first, or "high-stage," circuit to cool the second circuit.

It is exceptionally energy-efficient and has a GWP of only 3. This makes it a vastly more responsible choice than the HFCs it replaces.

R170 (Ethane): The Low-Stage Specialist

The second, "low-stage," circuit is responsible for the final pull-down to ultra-low temperatures (-80°C). R170 is ideal for this role.

Like R290, Ethane is a highly efficient natural hydrocarbon with a GWP of approximately 6. Using R170 in the low-stage circuit avoids the need for high-GWP synthetic gases.

Understanding the Trade-offs

While natural refrigerants are the clear choice for sustainability and efficiency, it's important to understand the full context of their use.

Efficiency and Compressor Technology

The efficiency of a freezer is not determined by the refrigerant alone. The fluid must work in harmony with the compressor.

Ongoing advancements in compressor technology are specifically designed to optimize performance with natural hydrocarbons, leading to lower energy consumption and reduced operating costs.

The High-GWP Alternative: R23

Some ULT freezers still use R23 (Trifluoromethane) in the low-temperature stage. While it is an effective refrigerant, it is an HFC with a GWP of over 14,000.

Choosing a freezer with R23 means accepting a significant, long-term environmental liability. As regulations on high-GWP gases tighten, these systems may also become more difficult or expensive to service.

Flammability: A Managed Risk

Natural hydrocarbons like propane and ethane are flammable. However, this risk is effectively managed in modern ULT freezer designs.

The amount of refrigerant used (the "charge") is extremely small, and the systems are hermetically sealed and built with robust safety features. These freezers are certified by safety agencies like UL for safe operation in a laboratory environment.

Making the Right Choice for Your Lab

When selecting a ULT freezer, use the refrigerant type as a key indicator of the unit's technological generation and environmental impact.

- If your primary focus is maximum sustainability and efficiency: Choose a freezer that uses a fully natural hydrocarbon cascade system, such as R290 in the high stage and R170 in the low stage.

- If you are evaluating an older or alternative model: Be critical of any system that uses R23 or other HFCs. You must weigh its performance against its extremely high Global Warming Potential.

- When comparing any freezers: Always look at the specification sheet for the exact refrigerants used and confirm their GWP is low. This metric is the most direct measure of the freezer's environmental impact.

By prioritizing systems with natural refrigerants, you are investing in a technology that is not only more efficient but also environmentally responsible.

Summary Table:

| Refrigerant | Type | Common Use in ULT Freezers | GWP (Global Warming Potential) |

|---|---|---|---|

| R290 (Propane) | Natural Hydrocarbon | High-Stage Circuit | ~3 |

| R170 (Ethane) | Natural Hydrocarbon | Low-Stage Circuit | ~6 |

| R23 (Trifluoromethane) | Synthetic HFC | Low-Stage Circuit (Legacy) | >14,000 |

Upgrade your lab's sustainability and efficiency with KINTEK.

Choosing the right Ultra-Low Temperature freezer is a critical decision for your laboratory's performance and environmental impact. KINTEK specializes in providing advanced lab equipment, including ULT freezers that utilize the latest natural refrigerant technology (like R290 and R170) for superior energy efficiency and a minimal carbon footprint.

Our experts can help you select the ideal equipment to meet your specific needs, ensuring you benefit from lower operating costs and enhanced environmental responsibility.

Contact KINTEK today to find the perfect, eco-friendly ULT freezer for your lab.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

People Also Ask

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- What is the fundamental of magnetron sputtering? Master High-Quality Thin Film Deposition

- What is sputtering technology? A Guide to Precision Thin Film Deposition

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems

- What are the disadvantages of DC magnetron sputtering? Key Limitations for Your Lab