At its core, operating a ball mill is a systematic, multi-step process. The procedure involves loading the mill cylinder with the material to be ground, adding the grinding media (such as steel balls), securely closing the chamber, and running the machine at a controlled speed. Once the desired particle size is achieved after a set duration, the machine is stopped, and the finished product is safely discharged.

Effective ball milling is not merely about following mechanical steps; it is about understanding and controlling the physics at play. Mastering the relationship between rotation speed, grinding media, and material charge is what separates inconsistent results from precise, repeatable particle size reduction.

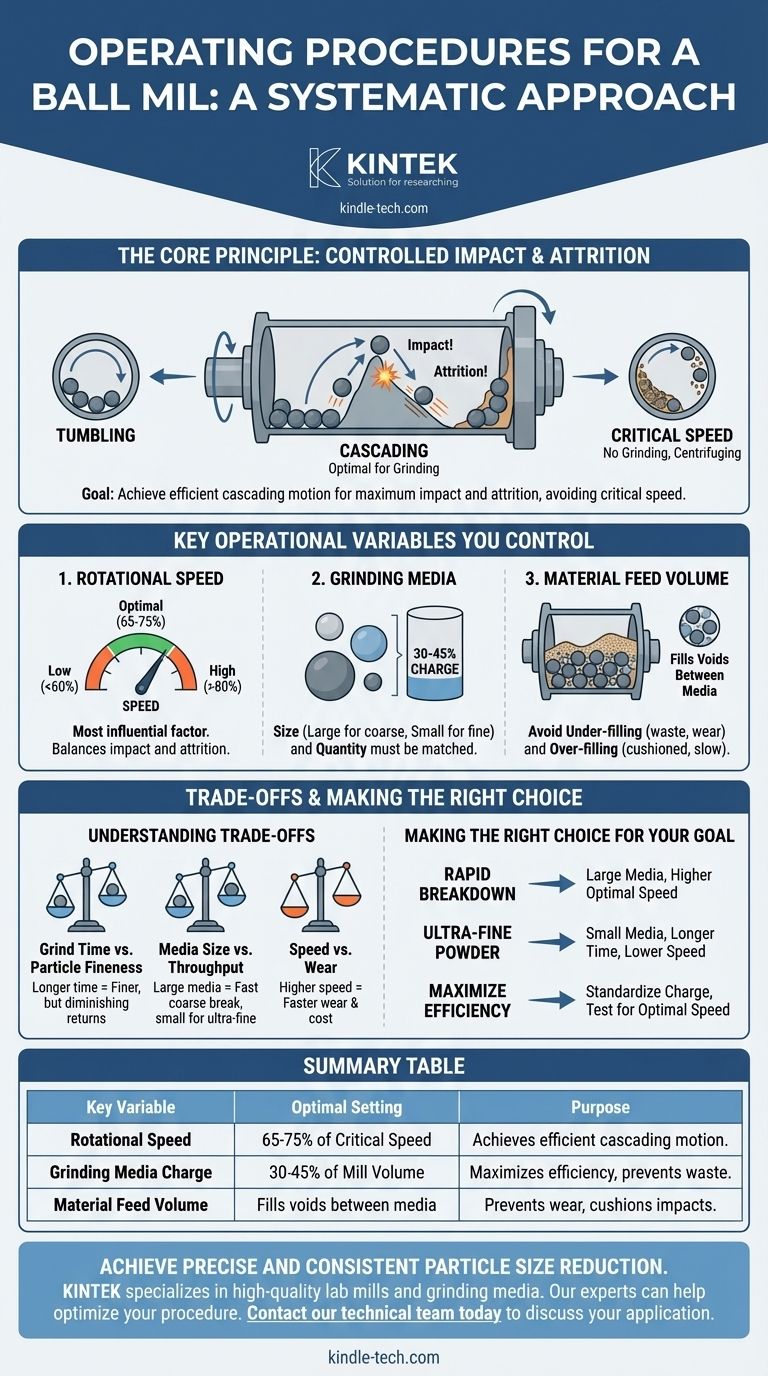

The Core Principle: Controlled Impact and Attrition

To operate a ball mill effectively, you must first understand its grinding mechanism. The goal is not random tumbling but a specific, energy-efficient motion.

From Tumbling to Cascading

As the mill cylinder rotates, it lifts the grinding media and the material. The key is to achieve a cascading motion, where the balls are carried up the side of the cylinder and then tumble and drop down onto the material below. This drop creates high-energy impact forces, which are the primary mechanism for breaking down coarse particles.

The Role of Attrition

As the balls cascade over one another, a secondary grinding action called attrition occurs. This is a shearing and rubbing force that is highly effective at reducing smaller particles into a very fine powder. The combination of impact and attrition ensures efficient grinding across a range of particle sizes.

Critical Speed: The Most Important Concept

If the mill rotates too slowly, the balls will only tumble at the bottom, resulting in inefficient grinding. If it rotates too quickly, it will reach critical speed, where centrifugal force pins the balls and material to the cylinder wall. In this state, no impact occurs, and grinding ceases entirely.

Key Operational Variables You Control

Your ability to produce a consistent product depends on how you manage three critical variables. Each step in the procedure is an opportunity to set these parameters correctly.

1. Rotational Speed

The operating speed is the most influential factor and is typically set as a percentage of the calculated critical speed.

- Low Speed (Below 60% of Critical): Maximizes attrition but minimizes impact. Useful for very fine grinding where breaking large particles is not the priority.

- Optimal Speed (65-75% of Critical): This range provides the best balance of impact and attrition for most applications, creating an efficient cascading motion.

- High Speed (Above 80% of Critical): The machine approaches centrifuging, reducing impact and efficiency while dramatically increasing wear on the mill lining and media.

2. Grinding Media

The balls themselves are a critical tool. Their size, material, and quantity must be matched to the job.

- Media Size: Large balls are used to break down large, coarse feed material. Smaller balls are more efficient at fine grinding because they create more contact points and reduce the empty space (voids) between media.

- Media Charge: This refers to the volume of the mill cylinder filled by the balls, typically around 30-45%. Too low a charge reduces grinding efficiency, while too high a charge can inhibit motion and cushion impacts.

3. Material Feed Volume

The amount of material you load into the mill is also crucial. The material fills the void spaces between the grinding balls.

- Under-filling: Leads to wasted energy as the balls primarily strike each other, causing excessive media and liner wear.

- Over-filling: Cushions the impact of the grinding media, drastically slowing down the particle size reduction process.

Understanding the Trade-offs

Every operational choice involves a trade-off. Recognizing these is key to troubleshooting and process optimization.

Grind Time vs. Particle Fineness

Longer grinding times will produce a finer product, but with diminishing returns. At a certain point, you will expend significant energy for very little change in particle size. Over-grinding can also sometimes lead to particle agglomeration.

Media Size vs. Throughput

Using large media will break down a coarse feed very quickly, but it will be unable to produce an ultra-fine product efficiently. Conversely, using small media from the start on a coarse feed will result in a very slow and inefficient process. For significant size reduction, a two-stage process (coarse then fine media) is often optimal.

Speed vs. Wear

Operating at higher speeds can shorten grinding time but will accelerate the wear and tear on the mill's liner and the grinding balls themselves. This increases maintenance costs and consumable expenses over time.

Making the Right Choice for Your Goal

Your standard operating procedure should be adjusted based on your primary objective.

- If your primary focus is rapid breakdown of coarse material: Use larger grinding media and operate at the higher end of the optimal speed range (around 75% of critical speed).

- If your primary focus is achieving an ultra-fine powder: Use smaller grinding media and a longer grinding time, potentially at a slightly lower speed to favor attrition.

- If your primary focus is maximizing efficiency and consistency: Standardize your media charge and material volume, and run tests to identify the precise optimal speed for your specific material.

By moving beyond a simple checklist and understanding these core principles, you gain precise control over the quality and consistency of your final product.

Summary Table:

| Key Operational Variable | Optimal Setting | Purpose |

|---|---|---|

| Rotational Speed | 65-75% of Critical Speed | Achieves efficient cascading motion for impact & attrition. |

| Grinding Media Charge | 30-45% of Mill Volume | Maximizes grinding efficiency and prevents energy waste. |

| Material Feed Volume | Fills voids between media | Prevents excessive wear and cushions impacts. |

Achieve precise and consistent particle size reduction in your lab.

Operating a ball mill effectively requires the right equipment and expert guidance. KINTEK specializes in high-quality lab mills, grinding media, and consumables, providing the reliable tools you need to master your milling process.

Our experts can help you select the perfect mill and optimize your procedure for your specific material and desired particle size.

Contact our technical team today to discuss your application and ensure your grinding success.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of a ball mill in WCp/Cu FGM preparation? Achieve Uniform Powder Dispersion

- What is the technical significance of adjusting ball mill rotation speeds to low levels? Optimize Composite Cathodes

- What is the function of an agate mortar and pestle? Ensure Purity in Halide Solid-State Electrolyte Synthesis

- What is the primary function of mechanical grinding equipment in the physical modification of lignin?

- What are 5 uses of hammer mill? Unlock Versatile Size Reduction for Your Industry

- What is a colloid mill also known as? Discover the Rotor-Stator Mill for High-Shear Processing

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the difference between a ball mill and a rod mill? Choose the Right Grinding Mill for Your Needs