The primary parameters of ball mill design are the mill's physical diameter, its rotational speed, the size and type of grinding media used, the volume of material being processed (solids loading), and the duration of grinding (residence time). These five variables are the fundamental levers you can adjust to control the final particle size and overall efficiency of the milling process.

The core challenge in ball mill design is not merely knowing these parameters, but understanding how they interact. Effective milling is a balancing act between impact forces (for breaking large particles) and abrasion forces (for grinding fine powders), and every parameter adjustment shifts this balance.

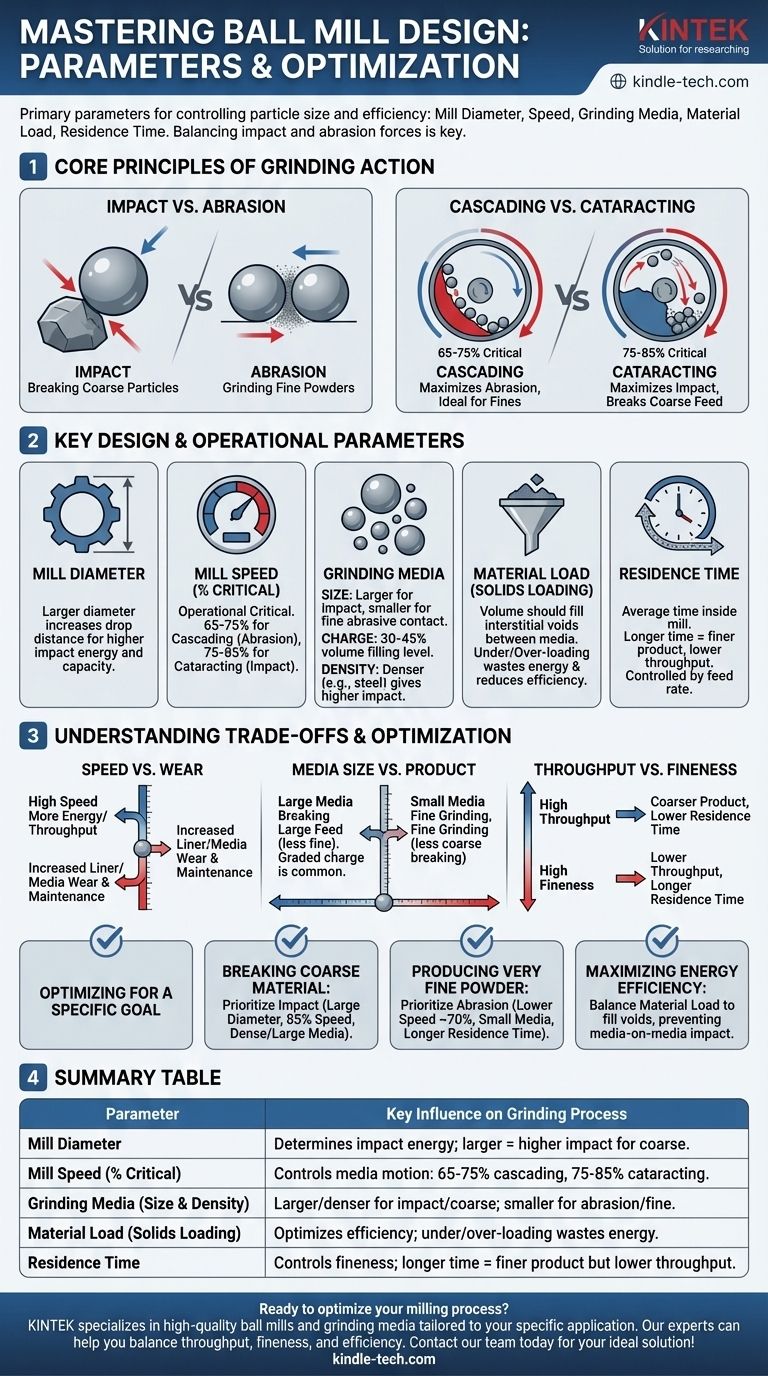

The Core Principles of Grinding Action

To effectively control a ball mill, you must first understand the two primary mechanisms of size reduction happening inside the chamber. Every design parameter is simply a way to influence these forces.

Impact vs. Abrasion

Impact is the forceful collision of the grinding media (the balls) with the material, acting like thousands of tiny hammer blows. This action is most effective for breaking down larger, coarse particles.

Abrasion (or attrition) is the shearing and rubbing action that occurs as balls slide and tumble past each other with the material trapped between them. This is the dominant force for grinding particles into very fine powders.

Cascading vs. Cataracting

The behavior of the media, dictated by the mill's speed, determines which grinding force dominates.

Cascading occurs at lower speeds, where the balls tumble down the face of the media charge. This maximizes abrasion and is ideal for producing a fine final product.

Cataracting occurs at higher speeds, where the balls are thrown into the air before crashing down onto the material. This maximizes impact and is used for breaking down coarse feed material quickly.

Key Design & Operational Parameters

Each of the following parameters must be considered in relation to the others to achieve a specific grinding objective.

Mill Diameter

The diameter of the mill shell is a primary design choice. A larger diameter increases the drop distance for cataracting media, which generates significantly higher impact energy and allows for the processing of larger feed sizes. It is a fundamental factor in the mill's power draw and overall capacity.

Mill Speed (Critical Speed)

This is the most critical operational parameter. It's defined as a percentage of critical speed—the theoretical speed at which the media would be pinned to the mill shell by centrifugal force.

Operating at 65-75% of critical speed typically results in a cascading action, favoring abrasion. Pushing the speed to 75-85% of critical speed induces a cataracting motion, favoring impact.

Grinding Media (The "Balls")

The media is the heart of the process, and its properties are crucial.

Media Size

The size of the grinding media dictates the type of grinding. Larger media creates higher impact forces for breaking coarse particles, while smaller media creates more surface area and contact points for the abrasive grinding of fine powders.

Media Charge (Filling Level)

This is the volume of the mill occupied by the grinding media, typically ranging from 30% to 45%. Too low a charge wastes energy, while too high a charge can inhibit the free motion of the media, reducing efficiency.

Media Density

Media can be made from steel, ceramic, or other materials. Denser media, like steel, delivers much higher impact energy per collision than lighter ceramic media, making it more suitable for coarse grinding applications.

Material Load (Solids Loading)

The volume of material to be ground should be sufficient to fill the empty spaces (interstitial voids) between the grinding media.

Under-loading the mill causes the media to strike itself, leading to wasted energy and accelerated wear on both the media and the mill liner. Over-loading cushions the media impacts, drastically reducing grinding efficiency.

Residence Time

For mills operating in a continuous feed mode, residence time is the average time the material spends inside the mill. It is controlled by the feed rate. A longer residence time results in a finer final product but lowers the overall throughput of the machine.

Understanding the Trade-offs

Optimizing a ball mill is always a matter of balancing competing factors. There is no single "best" setting.

Speed vs. Wear

Increasing mill speed provides more grinding energy and can increase throughput, but it comes at a significant cost. Higher speeds dramatically accelerate the wear and tear on the mill's internal liner and the grinding media itself, leading to higher maintenance costs and downtime.

Media Size vs. Final Product

While large media is essential for breaking large feed, it is inefficient at producing ultra-fine powders because it has fewer contact points. Conversely, small media is perfect for fine grinding but is incapable of breaking large, hard particles. This is why many operations use a graded charge with a mix of media sizes.

Throughput vs. Fineness

There is a direct and unavoidable trade-off between how much material you can process (throughput) and how fine you can make it. Achieving a very fine particle size requires a longer residence time, which means reducing the feed rate and lowering overall throughput.

Optimizing Your Mill for a Specific Goal

Your design and operational parameters should be dictated by your end goal.

- If your primary focus is breaking down large, coarse material: Prioritize impact forces by using a larger mill diameter, operating closer to 85% of critical speed (cataracting), and using large, high-density grinding media like steel.

- If your primary focus is producing very fine powder: Prioritize abrasion by operating at lower speeds around 70% of critical speed (cascading), using smaller media to maximize surface area contact, and ensuring sufficient residence time.

- If your primary focus is maximizing energy efficiency: Carefully balance the material load to just fill the media voids, preventing both media-on-media impact and over-cushioning, as this is where most energy is wasted.

Mastering these interconnected parameters transforms ball milling from a brute-force process into a precisely controlled engineering discipline.

Summary Table:

| Parameter | Key Influence on Grinding Process |

|---|---|

| Mill Diameter | Determines impact energy; larger diameter = higher impact for coarse grinding. |

| Mill Speed (% Critical) | Controls media motion: 65-75% = cascading/abrasion; 75-85% = cataracting/impact. |

| Grinding Media (Size & Density) | Larger/denser media for impact/coarse grinding; smaller media for abrasion/fine powder. |

| Material Load (Solids Loading) | Optimizes efficiency; under/over-loading wastes energy and accelerates wear. |

| Residence Time | Controls fineness; longer time = finer product but lower throughput. |

Ready to optimize your milling process? The right lab equipment is critical for achieving precise particle size and efficient operation. KINTEK specializes in high-quality ball mills and grinding media tailored to your specific application—whether you need high-impact force for coarse materials or fine abrasion for ultra-fine powders. Our experts can help you select the perfect configuration to balance throughput, fineness, and energy efficiency. Contact our team today to discuss your grinding challenges and find your ideal solution!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- Why is low-energy ball milling preferred during the preparation of LiPO2F2-modified sulfide solid electrolytes?

- What is the role of a ball milling system in the physical synthesis of wüstite nanoparticles? Key Mechanisms Explained

- Why are zirconia milling balls preferred for P2-type layered oxides? Ensure High Purity and Grinding Efficiency

- What dual processes can jet milling accomplish? Master Micronization and Classification in One Step

- What is the use of a micro pulverizer? Achieve Fine Grinding for Food, Pharma & Chemicals

- What is the critical role of high-energy ball mills in UHTC powders? Enhancing Sintering Efficiency and Reactivity

- How does a ball mill machine work? Master Impact and Attrition for Precise Grinding

- What is the function of a Wiley grinding mill in the processing of elephant grass? Optimize Your Chemical Analysis