At its core, a residential furnace is a system of coordinated parts designed to safely generate and distribute heat. The primary components of a typical modern gas furnace include a thermostat, control board, ignitor, gas valve, burners, heat exchanger, and blower motor. Older systems may use a pilot light and thermocouple instead of an electronic ignitor.

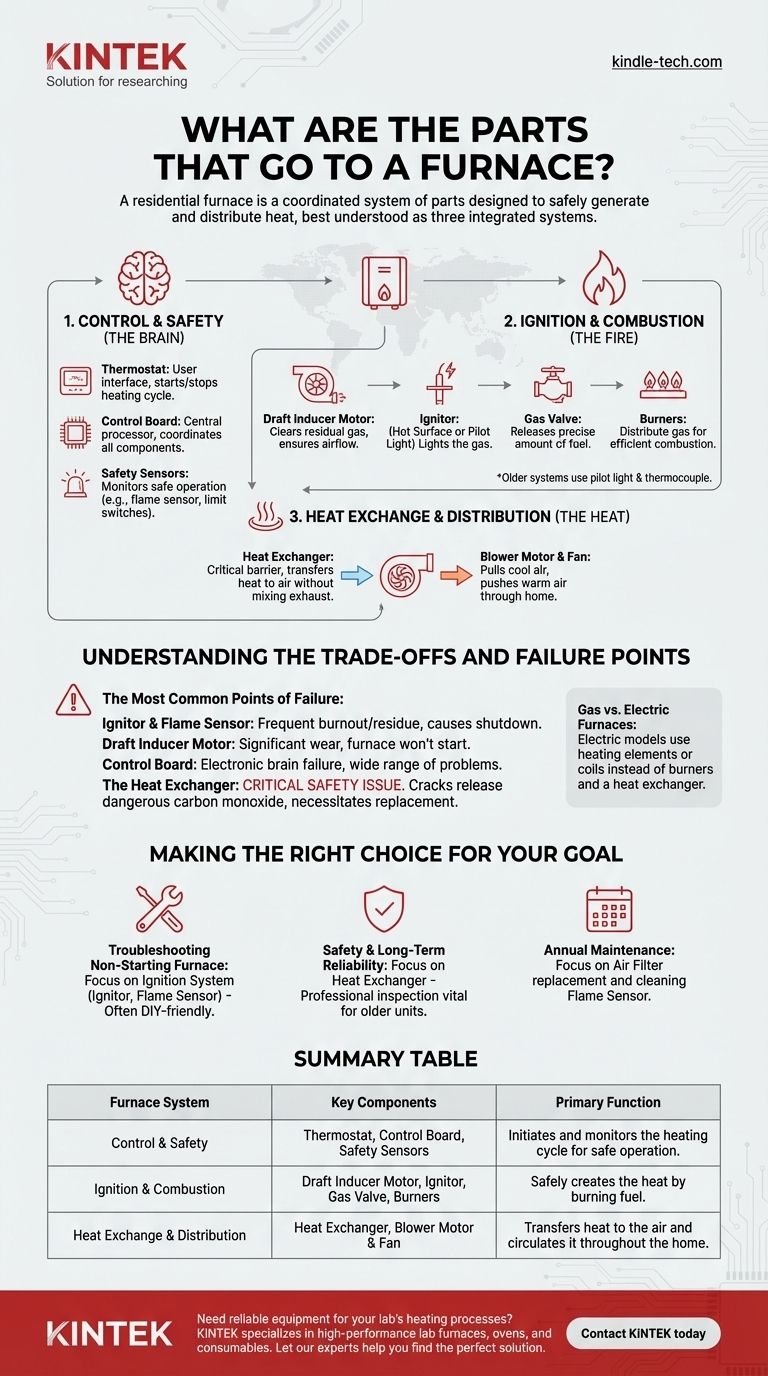

A furnace is best understood not as a single object, but as a sequence of three integrated systems: a Control & Safety system that calls for heat, an Ignition & Combustion system that creates the heat, and a Heat Exchange & Distribution system that delivers it to your home.

The Core Systems of a Gas Furnace

To truly understand your furnace, think of it as a logical process. The call for heat triggers a chain of events, with each component playing a specific role.

The Control System (The Brain)

This system initiates and monitors the entire heating cycle. It's the central nervous system of your furnace.

- Thermostat: The user interface for the entire HVAC system. While not physically inside the furnace cabinet, it sends the initial signal to start or stop the heating process.

- Control Board: This is the furnace's central processor. It receives the signal from the thermostat and coordinates the actions of all other components, from the ignitor to the blower.

- Safety Sensors: Crucial devices that monitor for safe operation. This includes the flame sensor, which confirms the burners have lit, and limit switches, which prevent the furnace from overheating.

The Ignition & Combustion System (The Fire)

Once the control board confirms it's safe to proceed, this system creates the heat.

- Draft Inducer Motor: This small fan runs first. It clears out any residual unburnt gas from the previous cycle and ensures a proper flow of air for combustion and exhaust.

- Ignitor: Modern furnaces use a hot surface ignitor, which is a small element that glows red-hot to light the gas. Older furnaces use a constantly burning pilot light for this purpose.

- Gas Valve: After the ignitor is hot, the control board signals the gas valve to open, releasing a precise amount of natural gas or propane to the burners.

- Burners: These are tubes that distribute the gas, allowing it to mix with air and combust cleanly and efficiently when ignited.

The Heat Exchange & Distribution System (The Heat)

This system’s job is to transfer the heat from combustion into the air and move that warm air through your home.

- Heat Exchanger: This is the critical barrier between the combustion gases and your breathable air. It's a sealed metal chamber that gets extremely hot from the burners. Air from your home blows over the outside of the heat exchanger, absorbing the heat without ever touching the toxic exhaust fumes.

- Blower Motor and Fan: This is the powerful fan that pulls cool air from your home's return ducts, pushes it across the hot heat exchanger, and then sends the newly warmed air into your supply ducts to heat your living spaces.

Understanding the Trade-offs and Failure Points

Knowing the parts is useful, but knowing what commonly fails is essential for troubleshooting.

The Most Common Points of Failure

- Ignitor & Flame Sensor: These are the most frequent failure points. The hot surface ignitor is fragile and burns out over time. The flame sensor can become coated with residue and fail to detect the flame, causing the furnace to shut down as a safety precaution.

- Draft Inducer Motor: Because this motor must start before every heating cycle, it undergoes significant wear and is a common point of failure, leading to a furnace that won't start.

- Control Board: As the electronic brain, a failure in the control board can cause a wide range of problems, from a completely dead furnace to erratic behavior.

- The Heat Exchanger: A failure here is the most serious. A crack in the heat exchanger can allow dangerous carbon monoxide to mix with your home's air. This is a critical safety issue and almost always necessitates a full furnace replacement.

Gas vs. Electric Furnaces

While most furnaces use gas, electric models exist. Their primary difference is the combustion system. Instead of burners and a heat exchanger, they use large heating elements or coils, similar to a giant toaster, to heat the air directly as the blower pushes it past.

Making the Right Choice for Your Goal

Your reason for learning about furnace parts dictates where you should focus your attention.

- If your primary focus is troubleshooting a non-starting furnace: Investigate the ignition system first. Check if the hot surface ignitor is glowing or if the flame sensor needs cleaning, as these are the most common and often DIY-friendly fixes.

- If your primary focus is safety and long-term reliability: Pay close attention to the heat exchanger. A professional inspection for cracks is vital on older units, as this represents the single biggest safety risk.

- If your primary focus is performing annual maintenance: Your key tasks are replacing the system's air filter (critical for airflow) and cleaning the flame sensor to ensure reliable operation.

By understanding how these components work together as a system, you can better diagnose problems, communicate with technicians, and maintain the safety of your home.

Summary Table:

| Furnace System | Key Components | Primary Function |

|---|---|---|

| Control & Safety | Thermostat, Control Board, Safety Sensors | Initiates and monitors the heating cycle for safe operation. |

| Ignition & Combustion | Draft Inducer Motor, Ignitor, Gas Valve, Burners | Safely creates the heat by burning fuel. |

| Heat Exchange & Distribution | Heat Exchanger, Blower Motor & Fan | Transfers heat to the air and circulates it throughout the home. |

Need reliable equipment for your lab's heating processes? KINTEK specializes in high-performance lab furnaces, ovens, and consumables, delivering the precision and safety your laboratory demands. Let our experts help you find the perfect solution for your application. Contact KINTEK today to discuss your needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What is the structure of a vacuum furnace? A Guide to Its Core Components & Functions