From a physical standpoint, synthetic diamonds possess characteristics that are virtually identical to those of natural, mined diamonds. They are made of the same element—carbon—arranged in the same crystal lattice structure, giving them the same supreme hardness and optical brilliance. The crucial differences are not visible to the naked eye but exist as microscopic "fingerprints" left by their different formation processes.

A synthetic diamond is not a "fake" diamond; it is a real diamond created in a laboratory. Its physical, chemical, and optical properties are the same as a natural diamond, with the only true distinctions being microscopic traces of their origin, detectable only with sophisticated scientific instruments.

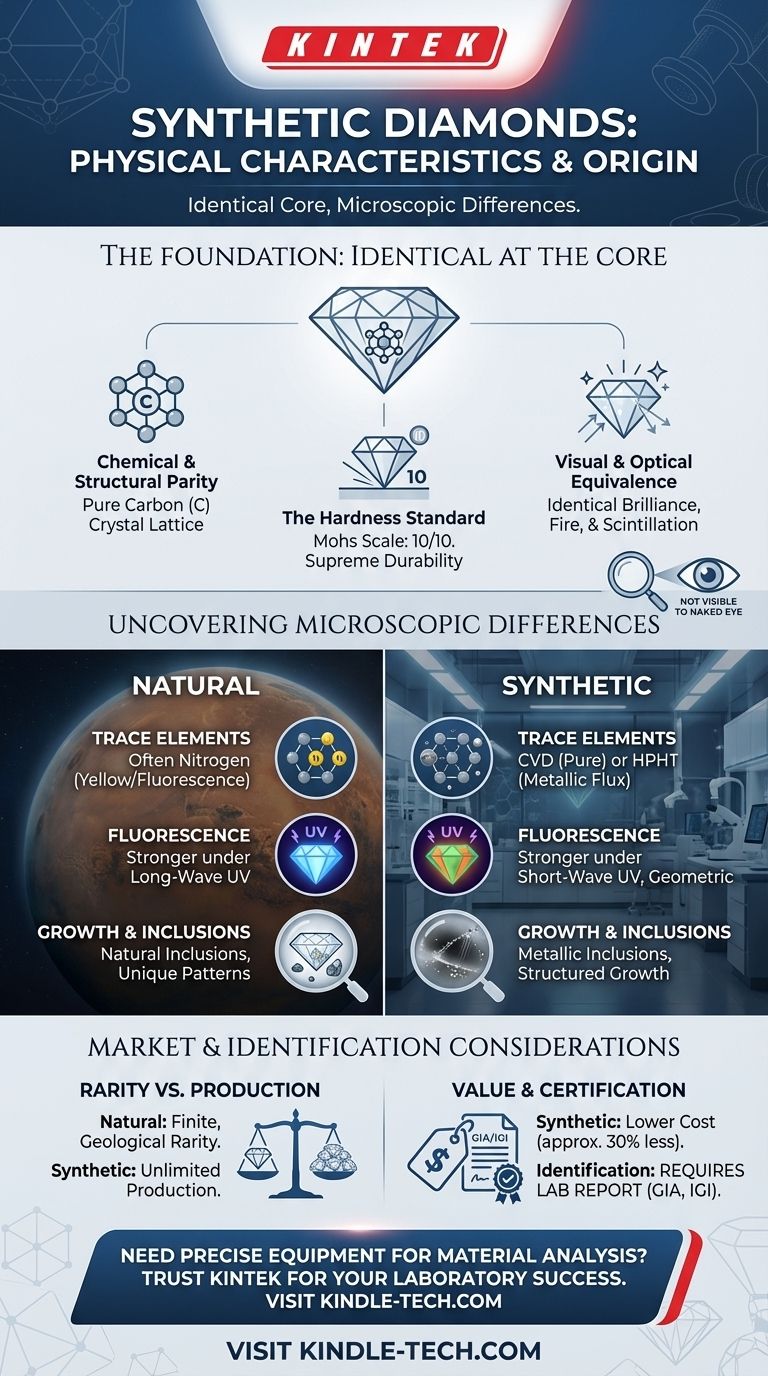

The Foundation: Identical at the Core

To understand synthetic diamonds, it's essential to first recognize that they are not simulants like cubic zirconia or moissanite. They are chemically and structurally diamonds.

Chemical and Structural Parity

A natural diamond is a crystal of carbon. A synthetic diamond, whether made through High Pressure/High Temperature (HPHT) or Chemical Vapor Deposition (CVD), is also a crystal of carbon.

Their internal atomic structure is identical. This shared structure is what grants them their defining physical properties.

The Hardness Standard

Both natural and synthetic diamonds register a 10 on the Mohs scale of hardness, the highest possible rating. This means a lab-created diamond is just as durable and resistant to scratching as its mined counterpart, making it equally suitable for daily wear in jewelry.

Visual and Optical Equivalence

A diamond's famous sparkle comes from its high refractive index and dispersion. Because synthetic diamonds have the same optical properties, they exhibit the same intense brilliance, fire, and scintillation as natural diamonds.

Without advanced testing, even a trained gemologist cannot visually distinguish a high-quality lab-grown diamond from a natural one.

Uncovering the Microscopic Differences

The distinction between natural and synthetic diamonds lies in the subtle evidence of their growth environments—the chaotic, high-pressure mantle of the Earth versus a controlled laboratory setting.

The Role of Trace Elements

Natural diamonds form over billions of years and almost always contain trace amounts of nitrogen, which can affect their color and fluorescence.

Synthetic diamonds have different impurities related to their manufacturing process. For example, HPHT diamonds may contain traces of metallic flux (like nickel), while CVD diamonds are exceptionally pure (Type IIa), a category that is very rare in natural diamonds.

Fluorescence as a Key Indicator

Fluorescence, a glow under ultraviolet (UV) light, is a primary method for differentiation. While both types can fluoresce, their behavior often differs.

Many synthetic diamonds exhibit stronger fluorescence under short-wave UV light, whereas fluorescing natural diamonds typically react more strongly to long-wave UV light. Furthermore, the pattern of fluorescence in a synthetic diamond can appear in a distinctive, unnatural geometric shape corresponding to its crystal growth structure.

Growth Structure and Inclusions

The growth patterns of lab-created diamonds are different from natural ones. These can be seen under magnification and are a definitive marker of a diamond's origin.

Similarly, the inclusions—tiny imperfections within the diamond—tell a story. Natural diamonds have natural inclusions like tiny crystals of other minerals. Synthetic diamonds may have tiny metallic inclusions left over from the growth process.

Understanding the Trade-offs

The physical similarities mask critical differences in market perception and value. Recognizing these is key to making an informed decision.

The Distinction Challenge

The single greatest challenge is that you, the end user, cannot verify a diamond's origin. You must place your trust in the gemological laboratories that issue grading reports.

This makes third-party certification from a reputable institution (like GIA or IGI) non-negotiable, as it is the only guarantee of whether you are purchasing a natural or lab-created stone.

Rarity vs. Production

The market value of natural diamonds is heavily tied to their finite supply and geological rarity. They are a limited resource.

Synthetic diamonds can be produced in potentially unlimited quantities. This fundamental difference in supply is why lab-created diamonds cost significantly less—often around 30% less for a stone of comparable size and quality.

Making the Right Choice for Your Goal

Your decision should be guided by your priorities, as both natural and synthetic diamonds are physically exceptional materials.

- If your primary focus is maximum visual impact for your budget: A synthetic diamond offers identical optical performance and durability at a significantly lower price point.

- If your primary focus is long-term value retention or the tradition of rarity: A natural diamond, with its geological origin and finite supply, remains the established choice.

- If your primary focus is absolute certainty and transparency: Insist on a grading report from a major gemological lab, which scientifically validates a diamond's characteristics and confirms its origin.

Ultimately, understanding these core physical truths empowers you to choose the diamond that aligns perfectly with your personal and financial priorities.

Summary Table:

| Characteristic | Natural Diamond | Synthetic Diamond |

|---|---|---|

| Chemical Composition | Carbon (C) | Carbon (C) |

| Crystal Structure | Diamond Cubic Lattice | Diamond Cubic Lattice |

| Hardness (Mohs Scale) | 10 | 10 |

| Optical Brilliance | Identical | Identical |

| Primary Distinction | Geological Origin & Trace Elements (e.g., Nitrogen) | Growth Method & Trace Elements (e.g., Metallic Flux in HPHT) |

| Key Identification Method | Grading Report (GIA, IGI) | Grading Report (GIA, IGI) |

Need precise, reliable equipment to analyze materials like diamonds?

At KINTEK, we specialize in high-performance lab equipment and consumables. Whether you're in gemology, materials science, or research, our tools provide the accuracy and reliability you need for critical analysis.

Let KINTEK empower your laboratory's success. Contact our experts today to find the perfect solution for your needs!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the best color for a lab created diamond? Maximize Value with a Smarter Choice

- Is synthetic the same as lab grown? Yes, and here's why it matters for your diamond choice.

- How long does it take to make a diamond in a machine? From Weeks to Billions of Years

- How long do lab-grown diamonds take to make? A 6-8 Week Journey from Seed to Gem

- Are CVD diamonds worth it? Unlock Brilliant Value & Ethical Clarity

- How much cheaper are CVD diamonds? Save 20-30% on a Genuine Diamond

- How does Microwave Plasma Chemical Vapour Deposition (MPCVD) work? Your Guide to High-Purity Diamond Film Growth

- What is the process of MPCVD? Grow High-Purity Diamond & Advanced Films