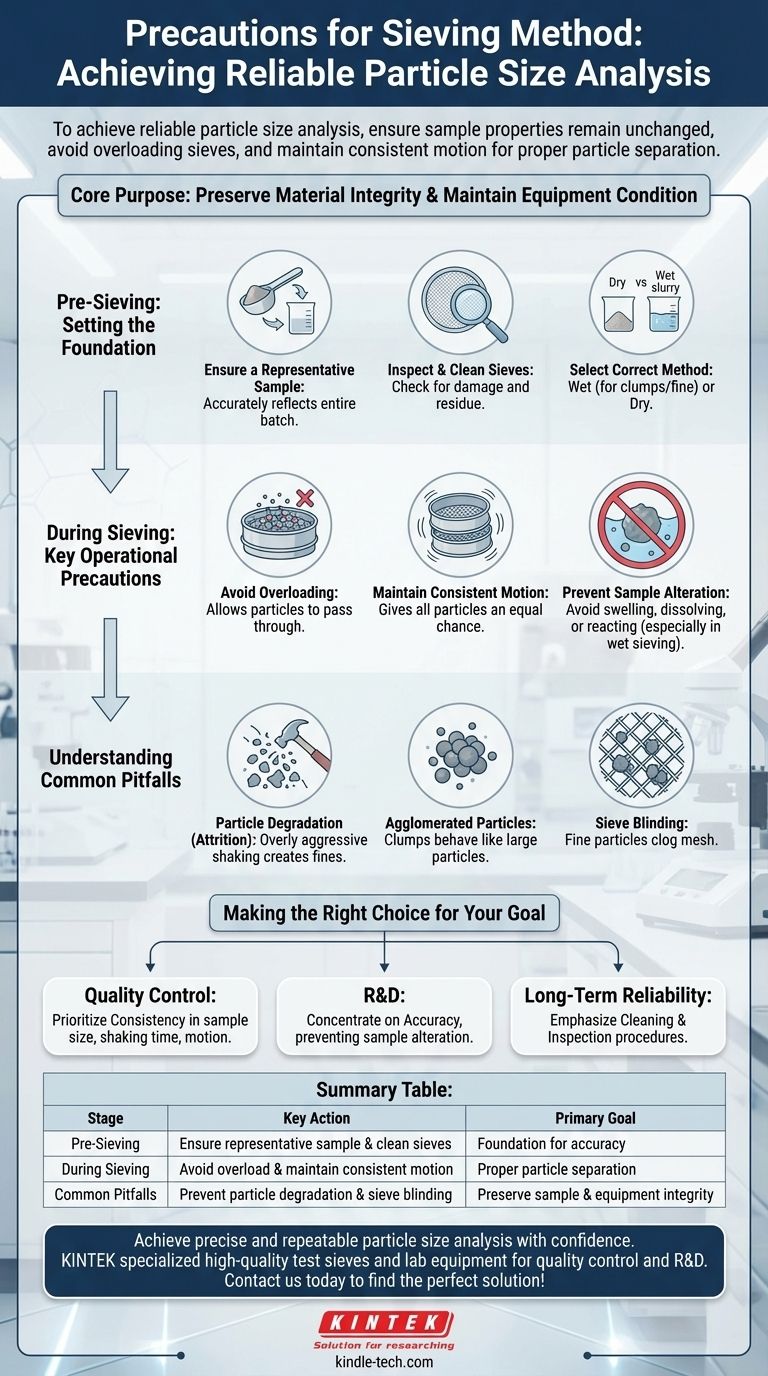

To achieve reliable particle size analysis, the most critical precautions for the sieving method are ensuring your sample's properties do not change during the process, avoiding overloading the sieves, and maintaining consistent motion to allow for proper particle separation. These steps are fundamental to preventing skewed results and ensuring the data is both accurate and repeatable.

The core purpose of all sieving precautions is twofold: to preserve the integrity of the material being tested for an accurate measurement and to maintain the condition of the sieving equipment for consistent, long-term use.

Pre-Sieving: Setting the Foundation for Accuracy

Before you begin the actual sieving process, a few preparatory steps are essential. Skipping these can invalidate your results before you even start.

Ensure a Representative Sample

The portion of material you test must accurately reflect the entire batch. If your sample is not representative, your particle size distribution data will be meaningless for the larger volume of material.

Inspect and Clean Your Sieves

Always check sieves for damage like tears or warping. Ensure the mesh is completely clean and unclogged from previous tests, as any remaining particles will obstruct the apertures and lead to inaccurate separation.

Select the Correct Sieving Method

The choice between wet and dry sieving is a critical precaution. Use wet sieving for materials that tend to clump together (agglomerate) or are very fine, but only if the liquid will not cause the particles to swell, dissolve, or react.

During Sieving: Key Operational Precautions

How you execute the sieving process directly impacts the quality of the separation and the final results.

Avoid Overloading the Sieve

Never place too much sample material onto a sieve at once. Overloading prevents individual particles from having the opportunity to reach the mesh surface and pass through, leading to an inaccurate retention of larger particles.

Maintain Consistent Motion

The principle of sieving relies on relative movement between the particles and the sieve mesh. Whether using a mechanical shaker or manual agitation, the motion must be consistent to give all particles an equal chance to be sorted by size.

Prevent Sample Alteration

This is especially critical during wet sieving. The liquid used must be inert. You must ensure the sample does not change in volume due to swelling, dissolving, or reacting with the liquid, as this would fundamentally alter the particle sizes you are trying to measure.

Understanding the Common Pitfalls

Even with careful procedure, certain material properties can introduce errors. Being aware of these is a key part of an effective sieving strategy.

The Risk of Particle Degradation

For friable or brittle materials, overly aggressive or prolonged shaking can break down the particles. This process, known as attrition, creates more fine particles and will skew your results toward a smaller particle size distribution.

The Challenge of Agglomerated Particles

Many fine powders tend to stick together due to moisture or electrostatic forces. These clumps behave like larger particles, preventing them from passing through the correct sieve mesh and leading to a false coarse reading.

The Impact of Sieve Blinding

Fine or near-size particles can become lodged in the mesh openings, a phenomenon called blinding. This effectively reduces the open area of the sieve and significantly lowers its efficiency, trapping material that should have passed through.

Making the Right Choice for Your Goal

Your specific objective determines which precautions are most critical to your success.

- If your primary focus is routine quality control: Prioritize consistency in sample size, shaking time, and motion to ensure your results are comparable from batch to batch.

- If your primary focus is research and development: Concentrate on preventing any physical or chemical alteration of your sample, as accuracy is paramount.

- If your primary focus is long-term equipment reliability: Emphasize rigorous inspection and cleaning procedures after every use to prevent damage and cross-contamination.

By applying these precautions diligently, you transform sieving from a simple task into a precise and reliable analytical method.

Summary Table:

| Precaution Stage | Key Action | Primary Goal |

|---|---|---|

| Pre-Sieving | Ensure representative sample & clean sieves | Foundation for accuracy |

| During Sieving | Avoid overload & maintain consistent motion | Proper particle separation |

| Common Pitfalls | Prevent particle degradation & sieve blinding | Preserve sample & equipment integrity |

Achieve precise and repeatable particle size analysis with confidence. The right sieving equipment is critical for adhering to these key precautions. KINTEK specializes in high-quality test sieves and lab equipment designed for accuracy and durability, serving the precise needs of laboratories in quality control and R&D. Contact us today (#ContactForm) to find the perfect sieving solution for your application and ensure your results are reliable every time.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment