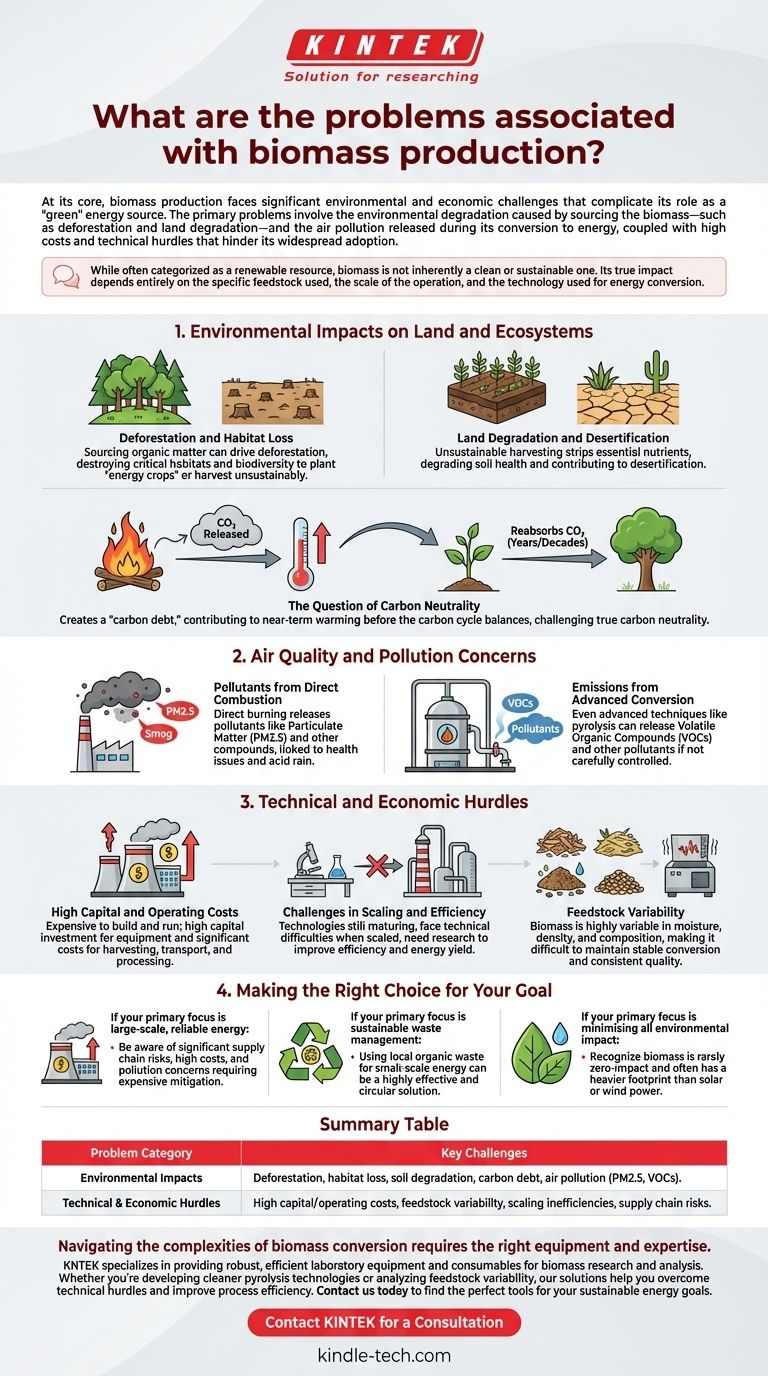

At its core, biomass production faces significant environmental and economic challenges that complicate its role as a "green" energy source. The primary problems involve the environmental degradation caused by sourcing the biomass—such as deforestation and land degradation—and the air pollution released during its conversion to energy, coupled with high costs and technical hurdles that hinder its widespread adoption.

While often categorized as a renewable resource, biomass is not inherently a clean or sustainable one. Its true impact depends entirely on the specific feedstock used, the scale of the operation, and the technology used for energy conversion.

Environmental Impacts on Land and Ecosystems

The most profound challenges of biomass are tied to the land required to produce it. Sourcing organic matter on an industrial scale exerts immense pressure on natural ecosystems.

Deforestation and Habitat Loss

When demand for biomass outstrips the supply from waste materials, it can drive deforestation. Forests may be cleared to plant dedicated, fast-growing "energy crops" or harvested unsustainably, leading to the destruction of critical habitats and a loss of biodiversity.

Land Degradation and Desertification

Unsustainable harvesting practices, where too much organic material is removed from fields or forests, can strip the soil of essential nutrients. This degrades soil health, reduces its ability to support life, and can contribute to desertification in arid regions.

The Question of Carbon Neutrality

Burning biomass releases carbon dioxide into the atmosphere immediately. While new plants will eventually reabsorb this CO2, this process takes years or even decades. This creates a "carbon debt," where biomass energy contributes to near-term warming before the carbon cycle can balance itself, challenging the idea that it is truly carbon neutral.

Air Quality and Pollution Concerns

Converting biomass into usable energy is not a zero-emission process. Whether through simple burning or advanced chemical conversion, pollutants are an unavoidable byproduct.

Pollutants from Direct Combustion

The most common method, direct burning, releases pollutants that harm air quality. These include particulate matter (PM2.5), which is linked to respiratory and cardiovascular diseases, and other compounds that contribute to smog and acid rain.

Emissions from Advanced Conversion

Even more advanced techniques like pyrolysis (heating biomass without oxygen) are not perfectly clean. These processes can release their own mix of pollutants, including volatile organic compounds (VOCs), if not carefully controlled and managed, presenting a different set of air quality challenges.

Technical and Economic Hurdles

Beyond the environmental footprint, significant practical barriers prevent biomass from becoming a dominant energy source. These are rooted in cost, technology maturity, and logistical complexity.

High Capital and Operating Costs

Building and running a biomass facility is expensive. The capital investment for reactors, turbines, and pollution control systems is high, and the costs of harvesting, transporting, and processing bulky biomass feedstock add up quickly.

Challenges in Scaling and Efficiency

Many biomass conversion technologies are still maturing and face technical difficulties when scaled up for industrial use. There is an ongoing need for research to improve process efficiency and increase the final energy yield, making it a riskier investment than more established technologies.

Feedstock Variability

Unlike uniform fossil fuels, biomass is highly variable. Differences in moisture content, density, and chemical composition from one batch to the next (feedstock variability) make it difficult to maintain a stable, efficient conversion process and ensure consistent product quality.

Making the Right Choice for Your Goal

Evaluating biomass requires understanding that its viability is context-dependent. The right approach depends entirely on your primary objective.

- If your primary focus is large-scale, reliable energy: Be aware that biomass presents significant feedstock supply chain risks, high costs, and pollution concerns that require expensive mitigation.

- If your primary focus is sustainable waste management: Using local agricultural, forestry, or municipal organic waste for small-scale energy production can be a highly effective and circular solution.

- If your primary focus is minimizing all environmental impact: Recognize that while renewable, biomass is rarely a zero-impact solution and often carries a heavier environmental footprint than solar or wind power.

Ultimately, the responsible use of biomass energy hinges on prioritizing sustainable sourcing and deploying clean, efficient conversion technologies.

Summary Table:

| Problem Category | Key Challenges |

|---|---|

| Environmental Impacts | Deforestation, habitat loss, soil degradation, carbon debt, air pollution (PM2.5, VOCs). |

| Technical & Economic Hurdles | High capital/operating costs, feedstock variability, scaling inefficiencies, supply chain risks. |

Navigating the complexities of biomass conversion requires the right equipment and expertise. KINTEK specializes in providing robust, efficient laboratory equipment and consumables for biomass research and analysis. Whether you're developing cleaner pyrolysis technologies or analyzing feedstock variability, our solutions help you overcome technical hurdles and improve process efficiency. Contact us today to find the perfect tools for your sustainable energy goals.

Contact KINTEK for a Consultation

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Evaporation Boat for Organic Matter

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success