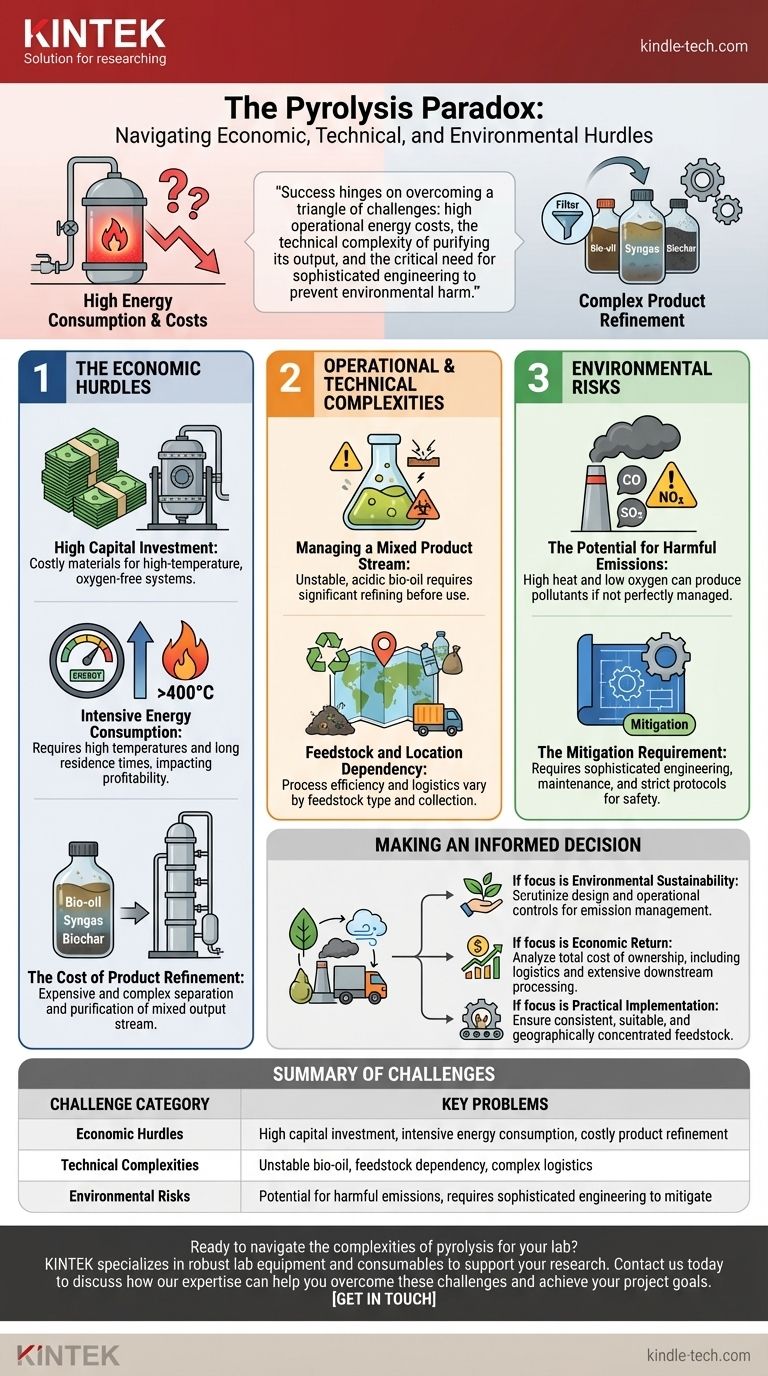

In short, the primary problems with pyrolysis are its high energy consumption, significant capital costs, complex product refinement needs, and the potential for harmful air emissions if not properly engineered and operated. These factors create substantial economic and environmental hurdles to its widespread adoption.

While pyrolysis is a powerful technology for converting waste into valuable products, its real-world viability is not guaranteed. Success hinges on overcoming a triangle of challenges: high operational energy costs, the technical complexity of purifying its output, and the critical need for sophisticated engineering to prevent environmental harm.

The Economic Hurdles of Pyrolysis

For many, the initial appeal of turning waste into fuel or other products is primarily economic. However, the financial realities of pyrolysis can be challenging and must be carefully evaluated.

High Capital Investment

The equipment required for a pyrolysis system, including the reactor, is costly. The process demands materials that can withstand very high temperatures in an oxygen-free environment, which increases manufacturing expense and the initial financial barrier to entry.

Intensive Energy Consumption

Pyrolysis is an energy-intensive process. It requires high temperatures, often over 400°C (750°F), and long residence times to effectively break down feedstock. This translates directly to high operational costs, impacting the overall profitability of the system.

The Cost of Product Refinement

The output of pyrolysis is not a single, ready-to-use product. It's a mixed stream of bio-oil, syngas, and biochar. Separating and purifying these products is a complex and often expensive process, adding another layer of cost that is frequently underestimated.

Operational and Technical Complexities

Beyond the economics, the day-to-day operation and technical requirements of pyrolysis present their own set of difficulties.

Managing a Mixed Product Stream

The liquid bio-oil produced is often acidic, unstable, and requires significant refining before it can be used as a transportation fuel. This is a major technical hurdle that makes it less of a simple "drop-in" replacement for conventional fuels.

Feedstock and Location Dependency

Pyrolysis is not a universal solution for all types of waste. The process efficiency can vary dramatically based on the type and consistency of the feedstock. Furthermore, the logistics of collecting and transporting biomass to a central plant can make the process unfeasible in certain locations.

Understanding the Trade-offs: Environmental Risks

While often promoted as an environmentally friendly technology, pyrolysis carries inherent risks that must be managed through careful design and operation.

The Potential for Harmful Emissions

The combination of high temperatures and a low-oxygen environment can produce unwanted byproducts and emissions that negatively impact air quality. Pollutants can be released if the system is not perfectly sealed or if the combustion of the resulting syngas is incomplete.

The Mitigation Requirement

Minimizing these environmental risks is possible but requires sophisticated engineering, diligent maintenance, and strict operational protocols. This adds to both the initial capital cost and the ongoing operational expense, creating a direct trade-off between environmental safety and economic viability.

Making an Informed Decision on Pyrolysis

To determine if pyrolysis is the right solution, you must align the technology's capabilities and limitations with your specific objectives.

- If your primary focus is environmental sustainability: Scrutinize the system's design and operational controls for managing emissions, as this is the critical factor separating a clean process from a polluting one.

- If your primary focus is economic return: Analyze the total cost of ownership, including feedstock logistics, energy inputs, and the extensive downstream processing required to create marketable products.

- If your primary focus is practical implementation: Ensure you have a consistent, suitable, and geographically concentrated feedstock, as process efficiency and logistics are highly dependent on the raw material.

Understanding these challenges is the first step toward designing and deploying pyrolysis systems that are both profitable and genuinely sustainable.

Summary Table:

| Challenge Category | Key Problems |

|---|---|

| Economic Hurdles | High capital investment, intensive energy consumption, costly product refinement |

| Technical Complexities | Unstable bio-oil, feedstock dependency, complex logistics |

| Environmental Risks | Potential for harmful emissions, requires sophisticated engineering to mitigate |

Ready to navigate the complexities of pyrolysis for your lab?

At KINTEK, we specialize in providing robust lab equipment and consumables to support your pyrolysis research and development. Whether you're focused on sustainability, economic analysis, or process optimization, our solutions help you manage high temperatures, control emissions, and refine products efficiently.

Contact us today to discuss how our expertise can help you overcome these challenges and achieve your project goals. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- Why are vacuum pumps and pressure control systems necessary in an USP setup? Achieve High-Purity Powder Synthesis

- How does magnetron sputtering work? A Guide to High-Quality Thin Film Deposition

- What precautions should be taken during evaporation lab? Master High-Vacuum, High-Temperature Safety

- What are the applications of electron beam hardening? Achieve Precision Hardening for Critical Components

- What is the reactive magnetron sputtering method? Synthesize Advanced Compound Films for Your Lab

- What are the stages of melting metal? Mastering the 3-Step Process from Solid to Liquid

- What are the constituents of pyrolysis oil? Unlocking the Complex Chemistry of Bio-Oil

- How does a constant temperature reciprocating shaker influence adsorption kinetics? Optimize Your Pollutant Studies