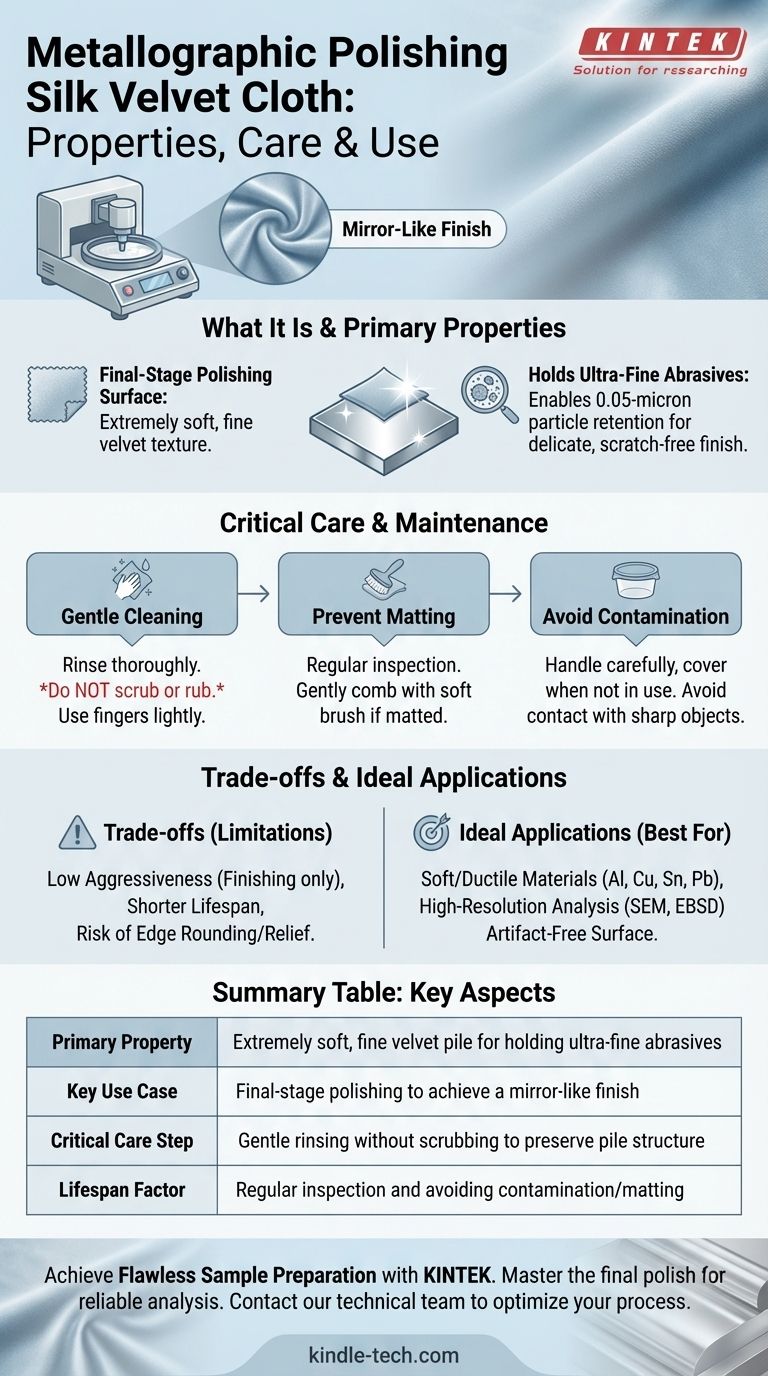

Metallographic polishing silk velvet cloth is a final-stage polishing surface prized for its extremely soft and fine velvet texture. Its primary property is its ability to hold fine abrasive particles, like 0.05-micron alumina or colloidal silica, to produce a delicate, mirror-like finish on a sample. Proper care involves gentle cleaning, avoiding physical damage, and regular inspection to ensure the velvet pile remains upright and effective.

The core challenge with silk velvet is preserving its delicate pile structure. This structure is not just for softness; it is the functional component that enables a scratch-free final polish, making its careful maintenance critical for achieving reliable, high-quality analytical results.

The Role of Silk Velvet in Final Polishing

The decision to use silk velvet cloth is a decision to prioritize surface quality above all else. It is the tool of choice for the very last step in a meticulous preparation process.

Achieving the "Mirror Finish"

Silk velvet is used exclusively for final polishing. Its purpose is to remove the last, finest scratches left by previous polishing stages, revealing the true microstructure of the material.

The cloth works in concert with a fine abrasive slurry. The soft pile holds the slurry and allows the abrasive particles to gently plane the surface without introducing new deformation or smearing.

The Importance of the Fine Pile

The "velvet" texture consists of a dense, upright pile. This structure is essential for holding a fresh, consistent layer of abrasive against the sample.

A healthy pile prevents contaminants from being dragged across the specimen, a phenomenon which causes "comet-tailing" artifacts around inclusions and pores.

Ideal Material Applications

This cloth is indispensable for soft, ductile materials like aluminum, copper, tin, and lead alloys, which are easily scratched or damaged by more aggressive surfaces.

It is also critical for any sample destined for high-resolution analysis, such as scanning electron microscopy (SEM) or electron backscatter diffraction (EBSD), where surface artifacts can obscure data or be misinterpreted as material defects.

Critical Care and Maintenance Procedures

The lifespan and effectiveness of a silk velvet cloth are entirely dependent on proper handling and care. Negligence here will directly translate to poor polishing outcomes.

Proper Cleaning Techniques

After each use, the cloth must be thoroughly cleaned to remove old abrasive and metal debris.

Rinse the cloth under a gentle stream of cool water. Do not scrub or rub it vigorously, as this will crush and mat the delicate pile, rendering it ineffective. Use your fingers lightly to help dislodge particles while rinsing.

Preventing and Correcting Matting

Over time, the pile can become matted or flattened. A matted cloth cannot hold the abrasive slurry properly and will produce inconsistent results.

Check the surface regularly. If matting occurs, you can sometimes restore the pile by gently combing it with a very soft brush while the cloth is damp.

Avoiding Contamination and Scratches

A single piece of grit or a scratch on the cloth itself can ruin countless samples. Always handle the cloth carefully and keep it covered when not in use.

Avoid any contact with sharp or rough objects. If the cloth becomes torn, nicked, or irreversibly contaminated, it must be replaced immediately.

Understanding the Trade-offs

While silk velvet is the gold standard for final polishing, it is not without its limitations. Understanding these trade-offs is key to using it effectively.

Low Aggressiveness

The primary benefit of silk velvet—its gentleness—is also a limitation. It has a very low material removal rate.

Using it prematurely in the polishing sequence is a waste of time and will not remove scratches from earlier, coarser grinding steps. It is strictly a finishing cloth.

Shorter Lifespan

Compared to tougher, napped, or napless cloths used for intermediate polishing, silk velvet is delicate. It will wear out more quickly and require more frequent replacement, representing a higher consumable cost.

Risk of Edge Rounding and Relief

The extreme softness of the cloth can cause issues if not used correctly. Prolonged polishing times can lead to edge rounding on the sample.

It can also create relief, where harder phases in the microstructure remain higher than softer phases that have been preferentially polished away. This requires skill and attention to polishing time and pressure to minimize.

Making the Right Choice for Your Goal

Use this guidance to determine when silk velvet is the correct tool for your specific metallographic objective.

- If your primary focus is preparing soft metals or polymers: Use silk velvet with a fine diamond or oxide suspension as your mandatory final step to avoid smearing and scratching.

- If your primary focus is failure analysis or high-magnification imaging: Use silk velvet to create a pristine, artifact-free surface that ensures you are analyzing the material itself, not preparation defects.

- If your primary focus is routine, high-volume quality control on hard materials: You may be able to achieve acceptable results with a more durable, all-in-one cloth to save time and cost, unless a mirror finish is explicitly required.

Mastering the use and care of silk velvet cloth is a direct investment in the quality and reliability of your microstructural analysis.

Summary Table:

| Property / Care Aspect | Key Detail |

|---|---|

| Primary Property | Extremely soft, fine velvet pile for holding ultra-fine abrasives |

| Key Use Case | Final-stage polishing to achieve a mirror-like finish |

| Critical Care Step | Gentle rinsing without scrubbing to preserve pile structure |

| Lifespan Factor | Regular inspection and avoiding contamination/matting |

Achieve Flawless Sample Preparation with KINTEK

Mastering the final polish is critical for reliable microstructural analysis. KINTEK specializes in high-quality lab equipment and consumables, including precision polishing cloths and abrasives designed for demanding applications like SEM and EBSD.

Let our experts help you select the right consumables for your specific materials and analytical goals. Ensure your lab achieves consistent, artifact-free results.

Contact our technical team today to discuss your polishing needs and optimize your preparation process.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Automatic Laboratory Heat Press Machine

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Three-dimensional electromagnetic sieving instrument

- Vacuum Cold Mounting Machine for Sample Preparation

People Also Ask

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish

- How should a sample be installed onto the sample holder? Ensure Mechanical Stability & Electrical Integrity

- How does a laboratory hydraulic press contribute to MIC testing? Ensure Precision in Stainless Steel Specimens

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis