The most common and effective reactors for fast pyrolysis are fluidized bed reactors (both bubbling and circulating types) and ablative reactors. Other designs, such as auger and rotary kiln reactors, are also used, but the core challenge for any fast pyrolysis system is its ability to achieve extremely high rates of heat transfer to solid biomass in under two seconds. This rapid heating is the defining characteristic of the process, designed to maximize the yield of liquid bio-oil.

The central goal of fast pyrolysis is to convert biomass into liquid bio-oil with maximum efficiency. The choice of reactor is therefore dictated by one primary engineering challenge: how to heat solid, poorly conductive biomass particles to around 500°C almost instantaneously.

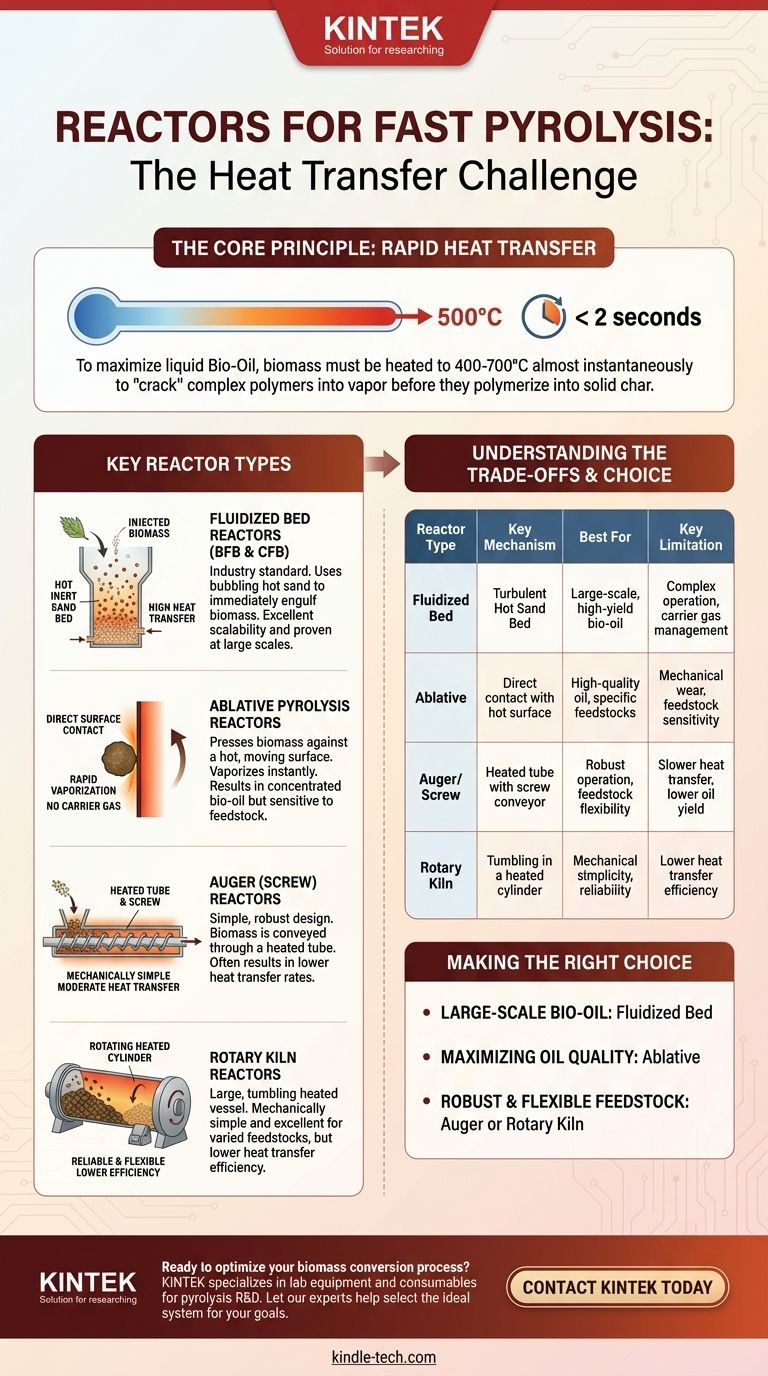

The Core Principle: Rapid Heat Transfer

To understand why certain reactors dominate, it's crucial to understand the fundamental requirement of the fast pyrolysis process itself.

Why Speed is Everything

Fast pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. To maximize the liquid bio-oil product, biomass must be heated very quickly (400-700°C) with a vapor residence time of less than two seconds.

This speed is critical. It ensures the complex polymers in biomass (cellulose, hemicellulose, and lignin) "crack" directly into vapor-phase molecules that can be condensed into oil. If heating is too slow, these intermediates have time to polymerize into solid char, reducing your primary product yield.

The Engineering Challenge

The main obstacle is that biomass is an excellent insulator. Getting heat into the core of a wood chip or a piece of straw quickly is difficult. The most successful fast pyrolysis reactors are those specifically designed to overcome this heat transfer limitation.

Key Reactor Types for Fast pyrolysis

The reactor designs best suited for this process use different mechanical strategies to achieve the necessary rapid heating.

Fluidized Bed Reactors (The Industry Standard)

This is the most mature and widely used technology for fast pyrolysis. It involves using a hot, inert material like sand as the heat transfer medium.

A hot gas is pumped through the sand bed, causing it to bubble and churn like a boiling fluid. When fine biomass particles are injected into this turbulent, intensely hot bed, they are immediately engulfed, resulting in exceptionally high heat transfer rates.

There are two main variants: Bubbling Fluidized Beds (BFB) and Circulating Fluidized Beds (CFB), with the latter being common for larger-scale operations.

Ablative Pyrolysis Reactors (A Different Approach)

Ablative reactors use a completely different principle. Instead of immersing the biomass in a hot medium, they press the biomass particles against a very hot, rapidly moving surface.

Think of it like melting butter in a hot pan. The instant the butter touches the surface, a thin layer melts. In ablative pyrolysis, the biomass particle's surface vaporizes instantly upon contact, and the pressure forces the particle against the surface until it is entirely consumed. This method transfers heat by direct conduction.

Auger (or Screw) Reactors

In an auger reactor, biomass is fed into one end of a heated tube and transported along its length by a large rotating screw. Heat is transferred from the hot tube walls to the biomass as it moves.

While mechanically simple, achieving the very high heat transfer rates needed for true fast pyrolysis can be a challenge. They often operate in a regime between slow and fast pyrolysis.

Rotary Kiln Reactors

A rotary kiln is a large, rotating cylindrical vessel. Biomass is fed in one end and tumbles through the hot kiln, with heat transferring from the reactor walls.

Similar to auger reactors, their mechanical simplicity is a major advantage. However, the heat transfer rate is typically lower than in fluidized bed systems, making them less common for applications focused purely on maximizing bio-oil yield.

Understanding the Trade-offs

No single reactor technology is perfect for every application. Each comes with a distinct set of advantages and disadvantages.

Fluidized Beds: Scalable but Complex

Fluidized bed reactors are the workhorse of the industry because they are proven at large scales and are relatively flexible regarding feedstock type and size.

However, they require a large volume of carrier gas to fluidize the bed, which must be managed downstream. Separating the fine biochar product from the much larger volume of bed material can also be an operational challenge.

Ablative Reactors: Efficient but Sensitive

The primary advantage of ablative reactors is that they do not require an inert carrier gas. This results in a more concentrated product vapor stream, which can lead to a higher quality bio-oil.

The main drawback is their sensitivity to feedstock. They require significant pressure to maintain contact with the hot surface, and the process is susceptible to mechanical wear. They work best with specific feedstock types and sizes.

Auger and Kiln Reactors: Simple but Slower

The key benefit of auger and rotary kiln reactors is their mechanical robustness and simplicity. They are excellent for reliably processing a wide variety of materials.

Their limitation, however, is heat transfer. It is difficult for these designs to achieve the near-instantaneous heating of fluidized beds, which often results in lower bio-oil yields and higher char production.

Making the Right Choice for Your Goal

The optimal reactor depends entirely on your specific objectives, from scale and feedstock to the desired end product.

- If your primary focus is large-scale, continuous bio-oil production: Fluidized bed reactors are the most developed and commercially proven technology for achieving high yields.

- If your primary focus is maximizing oil quality from a specific feedstock: Ablative reactors offer a compelling alternative that avoids carrier gas dilution but demands more precise operational control.

- If your primary focus is robust operation and feedstock flexibility over maximum oil yield: Auger or rotary kiln reactors provide a mechanically simple and reliable solution.

Ultimately, your choice of reactor is a direct trade-off between heat transfer efficiency, operational complexity, and the specific characteristics of your desired product.

Summary Table:

| Reactor Type | Key Mechanism | Best For | Key Limitation |

|---|---|---|---|

| Fluidized Bed | Turbulent hot sand bed | Large-scale, high-yield bio-oil | Complex operation, carrier gas management |

| Ablative | Direct contact with hot surface | High-quality oil, specific feedstocks | Mechanical wear, feedstock sensitivity |

| Auger/Screw | Heated tube with screw conveyor | Robust operation, feedstock flexibility | Slower heat transfer, lower oil yield |

| Rotary Kiln | Tumbling in a heated cylinder | Mechanical simplicity, reliability | Lower heat transfer efficiency |

Ready to optimize your biomass conversion process? The right reactor is critical for achieving high bio-oil yields. KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Our experts can help you select the ideal system for your specific feedstock and production goals. Contact us today to discuss how our solutions can enhance your laboratory's efficiency and success in bio-oil production!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- How do the stainless steel shell and the PTFE liner function differently in a high-pressure autoclave reactor?

- Why are high-strength alloys like Inconel preferred for small-capacity batch reactors? Ensure Safety & Precision

- Why are alumina ceramic liners integrated into SCWG reactors? Enhance Durability and Purity in Harsh Environments

- What role does a high-temperature and high-pressure reactor play in CoFe2O4/Fe synthesis? Unlock Core-Shell Precision

- What are the advantages of using a stainless steel cylindrical reactor? Maximize Photocatalytic Efficiency

- How does a Jet-Stirred Reactor (JSR) function? Mastering Anti-Coking Evaluation for High-Temperature Alloys

- Why are small stainless steel tube reactors ideal for subcritical water hydrolysis? Boost Biomass Research Efficiency

- How does a high-pressure hydrothermal synthesis reactor assist in reducing hazardous substances? Scavenging Formaldehyde