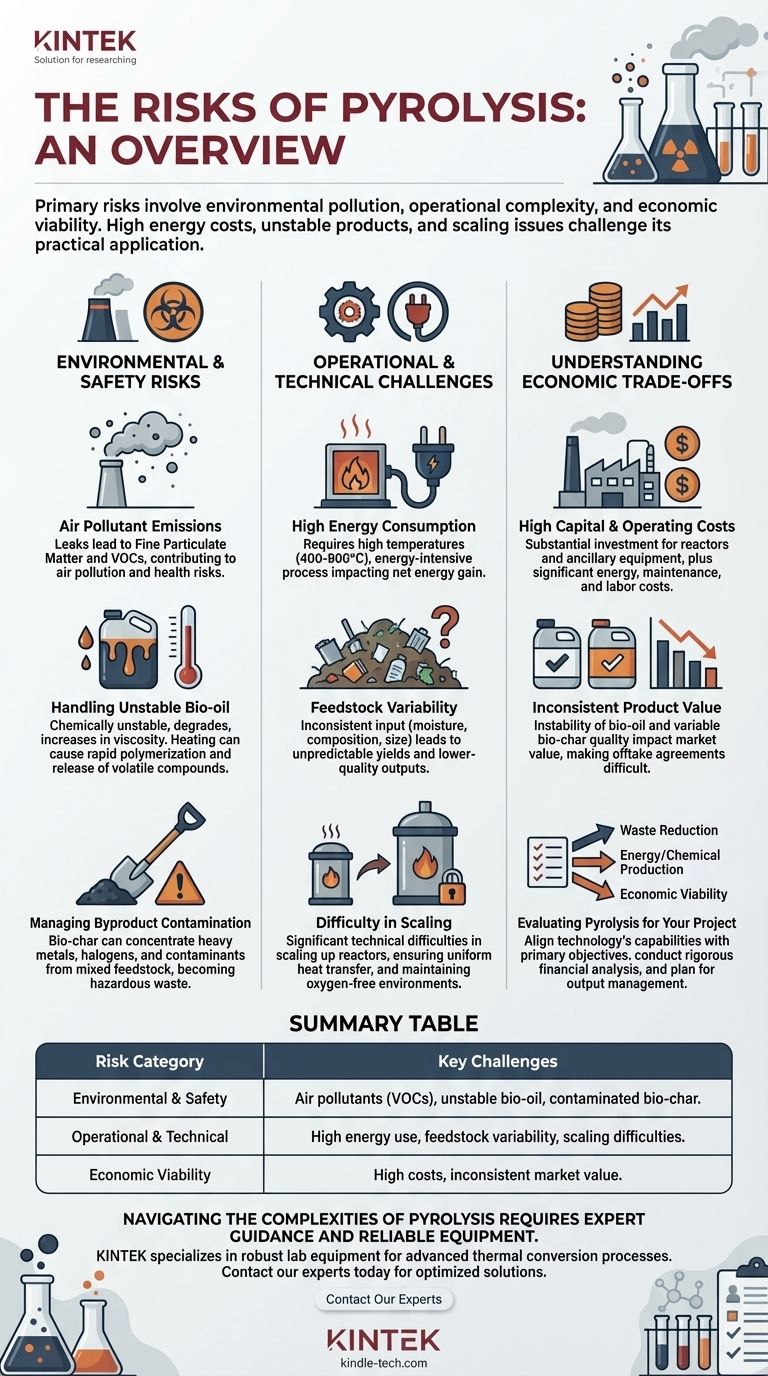

The primary risks of pyrolysis involve environmental pollution, operational complexity, and economic viability. The process can release harmful pollutants like volatile organic compounds (VOCs), the resulting bio-oil is often unstable and difficult to handle, and the high energy and capital costs can make it economically challenging to operate at scale.

While pyrolysis offers a promising method for converting waste into valuable resources, its practical application is not straightforward. The core challenge lies in managing the technical complexities and high costs required to mitigate its significant environmental and operational risks effectively.

Environmental and Safety Risks

The conversion process, while happening in a closed system, presents risks during material handling, operation, and management of its outputs.

Air Pollutant Emissions

Even in a controlled, oxygen-free environment, leaks or inefficient gas handling can lead to the emission of pollutants. These include fine particulate matter and volatile organic compounds (VOCs), which can contribute to air pollution and pose health risks.

Handling Unstable Bio-oil

The liquid product, known as bio-oil or pyrolysis oil, is often chemically unstable. It is composed of reactive compounds that can degrade over time, leading to a gradual increase in viscosity and even phase separation.

Heating this unstable oil can cause it to rapidly polymerize, creating solid residues and releasing more volatile compounds, which presents both a handling challenge and a safety hazard.

Managing Byproduct Contamination

The solid byproduct, bio-char, is often promoted as a useful soil amendment. However, if the initial feedstock (like mixed plastics or tires) contains heavy metals, halogens, or other contaminants, these substances can become concentrated in the bio-char, rendering it a hazardous waste that requires careful disposal rather than a valuable product.

Operational and Technical Challenges

Moving from a laboratory concept to an industrial facility reveals significant engineering and logistical hurdles.

High Energy Consumption

Pyrolysis requires heating materials to very high temperatures (typically 400-900°C). This process is inherently energy-intensive, and the energy required to run the system can offset a significant portion of the energy produced, impacting the overall net energy gain.

Feedstock Variability

The quality and composition of the final products are highly dependent on the consistency of the input material. Feedstock variability—such as changes in moisture content, chemical makeup, or physical size—can lead to unpredictable yields and lower-quality oil, gas, and char, making process control difficult.

Difficulty in Scaling

There are significant technical difficulties in scaling up pyrolysis reactors. Challenges related to ensuring uniform heat transfer, managing material flow, and maintaining an oxygen-free environment become exponentially more complex as the system size increases, creating reliability risks.

Understanding the Economic Trade-offs

Beyond the technical and environmental risks, the economic viability of a pyrolysis project is a critical consideration.

High Capital and Operating Costs

Building and running a pyrolysis plant involves substantial investment. High capital costs for the reactor and ancillary equipment, combined with significant operating costs for energy, maintenance, and labor, present a major financial risk.

Inconsistent Product Value

The instability of bio-oil and the variability of bio-char quality directly impact their market value. A lack of consistent, high-quality output makes it difficult to secure offtake agreements and can undermine the entire business model, which relies on selling these products to be profitable.

Evaluating Pyrolysis for Your Project

To determine if pyrolysis is the right solution, you must align the technology's capabilities with your primary objective.

- If your primary focus is environmental waste reduction: Prioritize systems with proven, robust gas cleanup and emission controls, and have a clear plan for safely managing all outputs, including potentially hazardous char.

- If your primary focus is energy or chemical production: Concentrate on securing a highly consistent and clean feedstock stream to ensure the production of stable, high-value oil that meets market specifications.

- If your primary focus is economic viability: Conduct a rigorous financial analysis comparing the high capital and operational costs against the realistic, often fluctuating, market value of the end products.

Ultimately, successfully implementing pyrolysis requires a pragmatic approach that balances its powerful potential with the disciplined management of its inherent risks.

Summary Table:

| Risk Category | Key Challenges |

|---|---|

| Environmental & Safety | Air pollutant emissions (VOCs, particulate matter), unstable bio-oil handling, contaminated bio-char byproduct |

| Operational & Technical | High energy consumption, feedstock variability, difficulties in scaling up reactors |

| Economic Viability | High capital and operating costs, inconsistent market value for end products |

Navigating the complexities of pyrolysis requires expert guidance and reliable equipment. KINTEK specializes in providing robust lab equipment and consumables tailored for advanced thermal conversion processes like pyrolysis. Whether you are focused on waste reduction, energy production, or economic viability, our solutions help you manage risks and optimize your operations. Contact our experts today to discuss how we can support your specific laboratory and project needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy