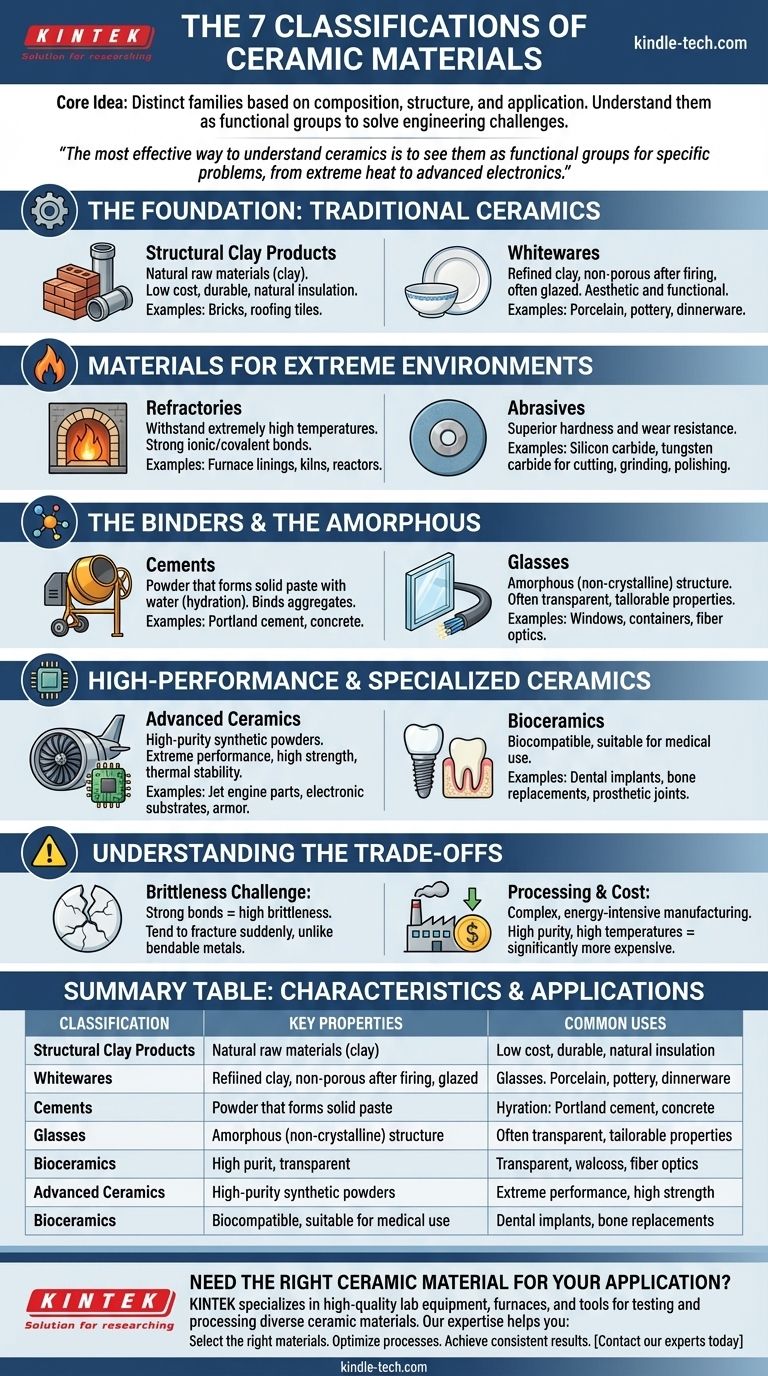

At its core, the world of ceramics is divided into distinct families based on composition, structure, and application. While various classification systems exist, a common and highly functional approach groups them into seven major categories: traditional ceramics (whitewares and structural clay), refractories, glasses, abrasives, cements, advanced ceramics, and bioceramics. Each class is defined by a unique set of properties that makes it suitable for specific engineering and commercial purposes.

The most effective way to understand ceramics is not to memorize a list, but to see the classifications as functional groups. Each category solves a specific set of problems, from withstanding extreme heat and providing structural integrity to enabling advanced electronics and repairing the human body.

The Foundation: Traditional Ceramics

Traditional ceramics are primarily derived from natural raw materials like clay, silica, and feldspar. They represent some of the oldest engineered materials used by humanity.

Structural Clay Products

These materials, including bricks, pipes, and roofing tiles, form the backbone of the construction industry. Their primary advantages are low cost, durability, and natural insulation properties.

Whitewares

This class includes more refined clay-based products like porcelain, pottery, and dinnerware. They are distinguished by their non-porous nature after firing and often feature a glazed surface for aesthetic and functional reasons.

Materials for Extreme Environments

Certain ceramic classes are defined by their ability to perform under severe mechanical and thermal stress. Their exceptional hardness and heat resistance come from strong ionic and covalent bonds.

Refractories

Refractories are materials designed to withstand extremely high temperatures without melting or degrading. They are essential for lining furnaces, kilns, and reactors used in steelmaking and other high-temperature industrial processes.

Abrasives

Valued for their superior hardness and wear resistance, abrasive ceramics like silicon carbide and tungsten carbide are used for cutting, grinding, and polishing other, softer materials. They are the working edge of saw blades, grinding wheels, and sandpaper.

The Binders and the Amorphous

Not all ceramics are crystalline solids used for their inertness. Some are defined by their ability to bind other materials, while others are defined by their lack of a crystalline structure altogether.

Cements

Cements, such as Portland cement, are unique in that they are supplied as a powder that forms a paste when mixed with water. They harden through a chemical reaction called hydration to form a solid, rock-like material that binds aggregates like sand and gravel to make concrete.

Glasses

The defining characteristic of glass is its amorphous (non-crystalline) structure. This lack of a regular atomic lattice is what makes most glasses transparent. By adding different chemicals, glass can be tailored for a vast range of applications, from windows to fiber optic cables.

High-Performance and Specialized Ceramics

This domain represents the cutting edge of materials science, where ceramics are engineered from highly purified synthetic powders to achieve exceptional properties.

Advanced Ceramics

Also known as engineering or technical ceramics, this class includes materials like alumina, zirconia, and silicon nitride. They are designed for extreme performance requirements, such as components in jet engines, electronic substrates, and ballistic armor, where their high strength, corrosion resistance, and thermal stability are critical.

Bioceramics

Bioceramics are a specialized subset of advanced ceramics characterized by their biocompatibility, meaning they can be placed within the human body without causing a negative reaction. They are used for medical applications like dental implants, bone replacements, and prosthetic joints.

Understanding the Trade-offs

While ceramics offer incredible performance in hardness and temperature resistance, their distinct atomic structure creates a fundamental limitation.

The Brittleness Challenge

The strong ionic and covalent bonds that give ceramics their strength also make them highly brittle. Unlike metals, which can bend and deform under stress, ceramics tend to fracture suddenly when a crack begins to propagate.

Processing and Cost

Manufacturing advanced ceramics is often a complex and energy-intensive process involving high-purity powders and very high firing temperatures. This can make them significantly more expensive than metals or polymers for a given component.

Making the Right Choice for Your Goal

Selecting the appropriate class of ceramic material depends entirely on the intended application and the primary problem you need to solve.

- If your primary focus is cost-effective construction: Traditional clay products and cements provide the necessary structural integrity and durability at a low cost.

- If your primary focus is withstanding extreme heat or wear: Refractories for thermal insulation and abrasives for cutting and grinding are the designated classes.

- If your primary focus is specialized performance for technology or medicine: Advanced ceramics and bioceramics offer engineered solutions with superior strength, purity, and biocompatibility.

Understanding these functional classifications transforms ceramics from a simple list of materials into a versatile toolbox for solving specific engineering challenges.

Summary Table:

| Classification | Key Characteristics | Common Applications |

|---|---|---|

| Traditional Ceramics | Natural raw materials (clay, silica), cost-effective | Bricks, tiles, dinnerware |

| Refractories | Exceptional heat resistance, withstands extreme temperatures | Furnace linings, kilns, reactors |

| Abrasives | Superior hardness and wear resistance | Cutting tools, grinding wheels, sandpaper |

| Cements | Powder that hardens with water (hydration) | Concrete, construction binders |

| Glasses | Amorphous (non-crystalline) structure, often transparent | Windows, containers, fiber optics |

| Advanced Ceramics | High-purity, engineered for extreme performance | Jet engine parts, electronic substrates, armor |

| Bioceramics | Biocompatible, designed for medical use | Dental implants, bone replacements, prosthetics |

Need the Right Ceramic Material for Your Application?

Understanding the distinct properties of each ceramic class is crucial for selecting the optimal material for your specific needs, whether for high-temperature processing, wear resistance, or biocompatibility. KINTEK specializes in providing high-quality lab equipment and consumables, including furnaces and tools designed for testing and processing various ceramic materials.

Our expertise can help you:

- Select the right materials for your R&D or production goals.

- Optimize your processes with reliable equipment built for performance.

- Achieve consistent results with consumables tailored to advanced material needs.

Let's discuss your project requirements. Contact our experts today to find the perfect solution for your laboratory challenges.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

People Also Ask

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- Why is pre-heating LLZO ceramic powder recommended? Optimize Interfaces for High-Performance Polymer Composites

- What are the effects of sintering temperature? Mastering the Balance Between Density and Microstructure

- What are the advantages of SiC technology? Achieve Higher Efficiency and Power Density

- What is the most biocompatible material for implants? A Guide to Titanium, Ceramics, and Polymers

- What is the maximum temperature for a ceramic tube? Find the Right Material for Your High-Temp Needs

- Why are porous ceramic filters utilized in methane pyrolysis? Protect Your Assets with High-Precision Filtration

- Why is density important in ceramics? It's the Key to Mechanical Strength and Performance