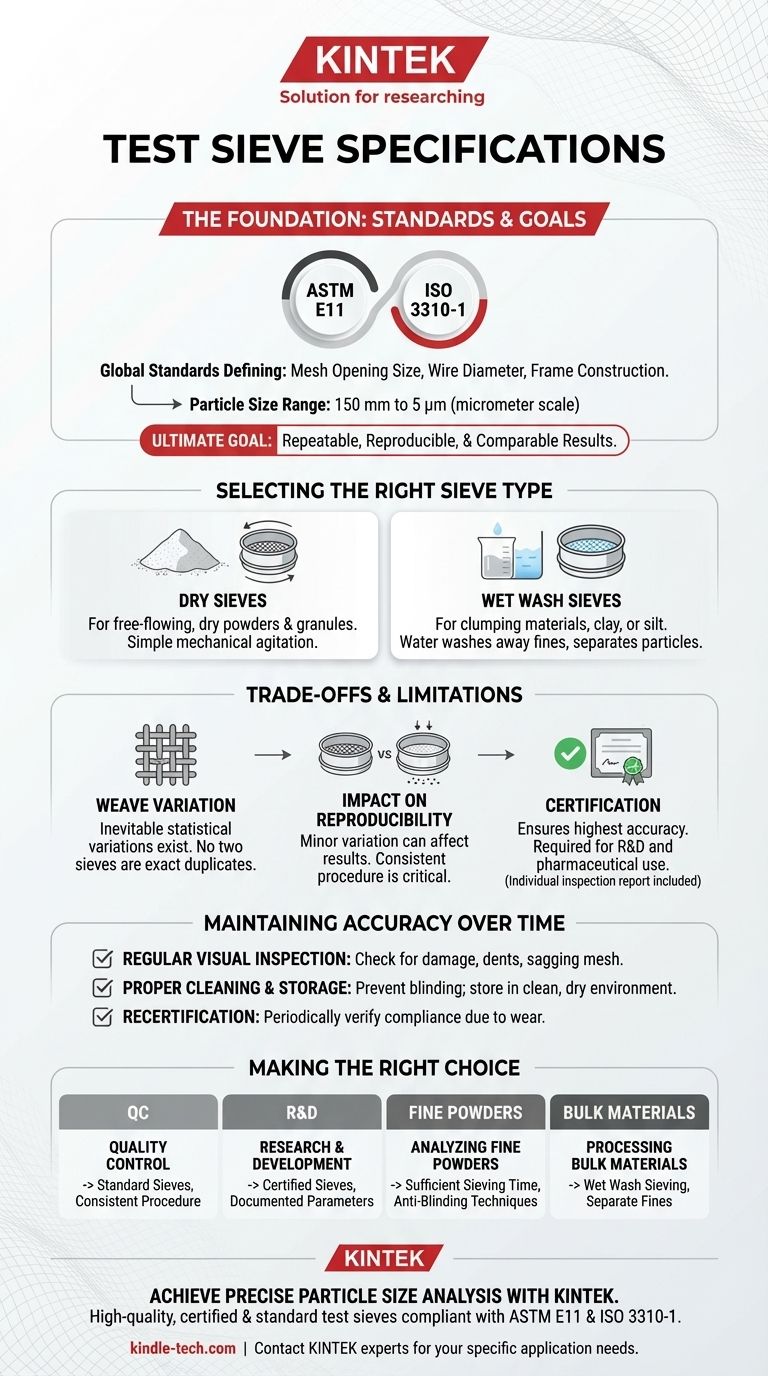

Test sieve specifications are primarily defined by international standards like ASTM E11 and ISO 3310-1. These standards govern every critical aspect of a sieve's construction, from the precise dimensions of the wire mesh openings to the material and height of the frame. The goal is to create a globally recognized, uniform tool for accurate particle size analysis, covering materials from 150 mm down to the micrometer scale.

The technical specifications of a test sieve are a means to an end. The ultimate goal is to ensure repeatable, reproducible, and comparable results in particle size analysis. Understanding the standards is less about memorizing numbers and more about selecting the right tool and process to achieve trustworthy data for your specific application.

The Foundation: ASTM E11 and ISO 3310-1

The integrity of any sieve analysis depends on the quality and uniformity of the sieves themselves. Industry standards create the framework for this consistency.

What These Standards Dictate

These comprehensive documents provide the manufacturing blueprint for a compliant test sieve. They specify the permissible range for nominal mesh opening size, the allowable wire diameter, the statistical distribution of aperture sizes, and the construction of the sieve frame.

Ensuring Manufacturing Precision

By setting strict quality thresholds, ASTM E11 and ISO 3310 hold manufacturers accountable for producing high-precision instruments. This ensures that a certified 200-mesh sieve from one manufacturer is functionally equivalent to one from another, allowing for comparable results across different labs.

The Particle Size Range

These standards are designed to cover a vast range of particle sizes. Woven wire mesh sieves can effectively separate materials with particles as large as 150 mm (about 6 inches) down to as fine as 5 µm (micrometers).

Selecting the Right Type of Sieve

Beyond the general specifications, sieves are designed for different types of materials and conditions. The fundamental choice is between dry and wet sieving methods.

Dry Test Sieves

These are the most common type of sieve. They are intended for use with free-flowing, dry powders and granular materials that can pass through the mesh openings with simple mechanical agitation, such as shaking or tapping.

Wet Wash Sieves

Wet wash sieves are required when particles clump together or are coated with very fine materials like clay or silt. Water is introduced to the process to wash away fines and help individual particles separate, allowing for an accurate size measurement. This is common in the soil and aggregate industries.

Understanding the Trade-offs and Limitations

Even with strict standards, a test sieve is a physical tool with inherent limitations. Acknowledging these is key to producing accurate data.

Inevitable Weave Variation

The process of weaving wire creates tiny, statistical variations in the mesh. While standards limit this variation, no two openings in a sieve are perfectly identical, and no two "identical" sieves are exact duplicates.

Impact on Reproducibility

This minor variation can impact the absolute reproducibility of results between different sieves. A particle may pass through one sieve but be retained by another of the same nominal size. This is why consistent procedure and data analysis methods are critical.

The Role of Certification

To account for this variability, sieves can be certified. A certified sieve has been individually inspected and measured, and it comes with a document detailing the statistical distribution of its actual aperture openings. This allows for the highest degree of accuracy and is often required for pharmaceutical and R&D applications.

Maintaining Accuracy Over Time

A sieve's specifications are only valid if the tool is properly maintained. Wear and damage can quickly render a sieve non-compliant and useless.

Regular Visual Inspection

Before each use, inspect sieves for any signs of damage, such as dents in the frame, sagging or torn mesh, or visible holes. A damaged sieve will produce invalid results.

Proper Cleaning and Storage

Thoroughly clean sieves after each use to prevent particles from becoming lodged in the mesh, a phenomenon known as blinding. Store them in a clean, dry environment where they will not be damaged.

The Need for Recertification

For critical applications, sieves should be periodically re-certified. Usage causes wear that can enlarge the mesh openings over time. Recertification verifies that the sieve still meets the required standard.

Making the Right Choice for Your Application

Your choice of sieve and testing protocol depends entirely on your end goal. Use the following guidelines to inform your approach.

- If your primary focus is routine quality control: Use a standardized set of sieves and a consistent procedure to detect process deviations quickly.

- If your primary focus is research and development: Use certified sieves and document all test parameters to ensure your data is highly accurate, defensible, and reproducible.

- If your primary focus is analyzing fine powders: Ensure your method includes sufficient sieving time and anti-blinding techniques to get an accurate result.

- If your primary focus is processing bulk materials (like aggregates): Use wet wash sieving to accurately separate fines and ensure a true measurement of the coarse particle distribution.

By understanding these principles, you can confidently select and maintain the right sieves to produce reliable and meaningful data for your project.

Summary Table:

| Key Specification | Description | Standard Reference |

|---|---|---|

| Nominal Opening Size | The designated size of the mesh apertures. | ASTM E11, ISO 3310-1 |

| Particle Size Range | Effective separation from 150 mm down to 5 µm. | ASTM E11, ISO 3310-1 |

| Sieve Type | Dry sieves for free-flowing powders; Wet wash sieves for clumping materials. | Application Dependent |

| Certification | Individual inspection report for high-accuracy R&D and pharmaceutical use. | Optional (Recommended) |

Achieve precise and reproducible particle size analysis with the right test sieves.

At KINTEK, we specialize in providing high-quality laboratory equipment, including a full range of certified and standard test sieves that comply with ASTM E11 and ISO 3310-1. Whether your focus is on rigorous R&D, routine quality control, or processing bulk materials, our experts can help you select the perfect sieving solution to ensure your data is accurate, reliable, and defensible.

Let KINTEK equip your lab for success. Contact our sieving experts today to discuss your specific application needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis