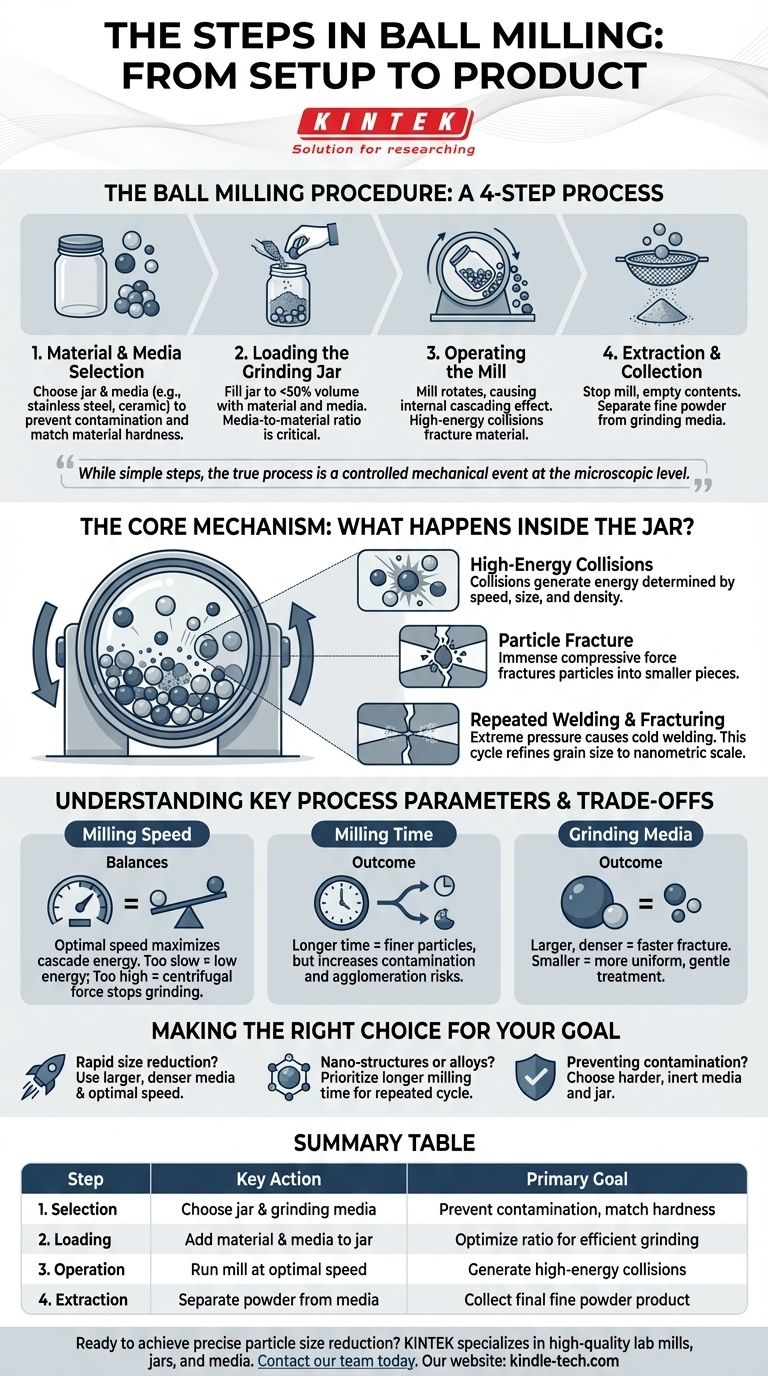

In practice, ball milling is a four-step mechanical process. It begins with selecting the appropriate grinding jar and media, followed by loading the material to be ground. The mill is then operated for a specific duration, causing the grinding media to pulverize the material. Finally, the resulting fine powder is separated from the grinding media and collected.

While the procedure of ball milling can be broken down into simple steps, the true process occurs at the microscopic level. It is a controlled mechanical event where high-energy collisions repeatedly fracture and cold-weld particles, fundamentally changing their size and structure.

The Ball Milling Procedure: From Setup to Product

The operational steps are straightforward, but each one serves to control the energetic environment inside the grinding jar.

Step 1: Material and Media Selection

The first step is preparing the equipment. This involves choosing a grinding jar and grinding media (such as balls).

To prevent contamination of the sample, the jar and balls are often made from the same material, which should be harder than the material being ground. Common options include stainless steel, tungsten carbide, or ceramic.

Step 2: Loading the Grinding Jar

The material to be ground is placed inside the jar along with the grinding media. The ratio of media to material is a critical parameter that dictates the efficiency of the process.

The jar is typically filled to less than half its volume to allow adequate room for the media to move and create impacts.

Step 3: Operating the Mill

The sealed jar is placed in a mill, which rotates it around a horizontal axis. As the jar rotates, the balls are lifted up the side of the jar and then cascade down, striking the material.

This internal cascading effect is the core of the grinding process, as it generates the mechanical energy needed to alter the material.

Step 4: Extraction and Collection

After running the mill for the designated time, the process is stopped. The contents of the jar are emptied, and the fine powder product is separated from the larger grinding media, typically using a sieve.

The Core Mechanism: What Happens Inside the Jar?

Understanding the procedure is only half the story. The true value comes from understanding the physical events that the procedure enables. All structural changes that occur are a direct result of mechanical energy.

High-Energy Collisions

As the jar rotates, the grinding balls are constantly colliding with each other, the jar wall, and the material particles trapped between them. Each collision is a high-energy impact event.

The energy of these impacts is determined by the mill's rotational speed, the size and density of the grinding balls, and the fill level of the jar.

Particle Fracture

During a collision, a material particle is caught between two surfaces (e.g., two balls or a ball and the jar wall). The immense compressive force causes the particle to fracture, breaking it into smaller pieces.

Repeated Welding and Fracturing

Simultaneously, the extreme pressure can cause fractured surfaces to instantly fuse back together in a process known as cold welding.

This cycle of repeated welding and fracturing is the key mechanism for grain size refinement. It transforms large particles into an aggregation of much smaller, nanometric-sized grains.

Understanding Key Process Parameters and Trade-offs

The outcome of ball milling is not guaranteed. It is highly dependent on the parameters you choose, each involving a specific trade-off.

Milling Speed: Finding the Balance

The rotational speed of the mill is critical. If the speed is too slow, the balls will simply slide against each other with low energy.

If the speed is too high, centrifugal force will pin the balls to the outer wall of the jar, preventing the cascading effect and stopping the grinding action entirely. The optimal speed maximizes the energy of the cascade.

Milling Time: A Double-Edged Sword

Longer milling times generally lead to finer particles. However, excessive time increases the risk of contamination from the wear of the jar and balls.

It can also lead to unwanted effects like particle agglomeration, where the fine powders begin to clump back together due to surface forces.

Grinding Media: Size and Density

Larger, denser balls create higher-energy impacts, leading to faster fracturing. However, they also result in fewer total impact points within the jar.

Smaller balls create a greater number of less-energetic impacts, which can be beneficial for processes that require a more uniform and gentle treatment.

Making the Right Choice for Your Goal

Your specific objective dictates how you should approach the process.

- If your primary focus is rapid particle size reduction: Use larger, denser grinding media and operate at the optimal cascading speed to maximize the fracture energy in each collision.

- If your primary focus is creating nano-structured materials or alloys: Prioritize a longer milling time to ensure the repeated fracture and cold-welding cycle is fully established, refining the internal grain structure.

- If your primary focus is preventing product contamination: Choose grinding media and a jar made of a material that is significantly harder than your sample and chemically inert.

By understanding these steps as a way to control the underlying mechanical forces, you can move from simply following a procedure to intelligently designing a process.

Summary Table:

| Step | Key Action | Primary Goal |

|---|---|---|

| 1. Selection | Choose jar & grinding media | Prevent contamination, match material hardness |

| 2. Loading | Add material & media to jar | Optimize media-to-material ratio for efficient grinding |

| 3. Operation | Run mill at optimal speed | Generate high-energy collisions for fracturing |

| 4. Extraction | Separate powder from media | Collect the final fine powder product |

Ready to achieve precise particle size reduction in your lab? The right ball milling equipment is critical for controlling the mechanical forces that fracture and refine your materials. At KINTEK, we specialize in high-quality lab mills, grinding jars, and media tailored to your specific application—whether you need rapid size reduction, nano-structuring, or contamination-free processing. Our experts can help you select the perfect setup to maximize your results. Contact our team today to discuss your ball milling needs and optimize your process!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Small Injection Molding Machine for Lab Use

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Powerful Plastic Crusher Machine

People Also Ask

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance