At its core, sputtering is a physical process for depositing thin films in a vacuum. It involves using energized ions from an inert gas, typically Argon, to physically bombard a source material (the "target"). This collision ejects atoms from the target, which then travel through the vacuum and condense onto a substrate, forming a highly uniform and controlled thin layer.

Sputtering is best understood as a game of atomic-scale billiards. The process uses high-energy ions as "cue balls" to knock atoms loose from a source material, which then deposit onto a component to form a precise, high-quality coating.

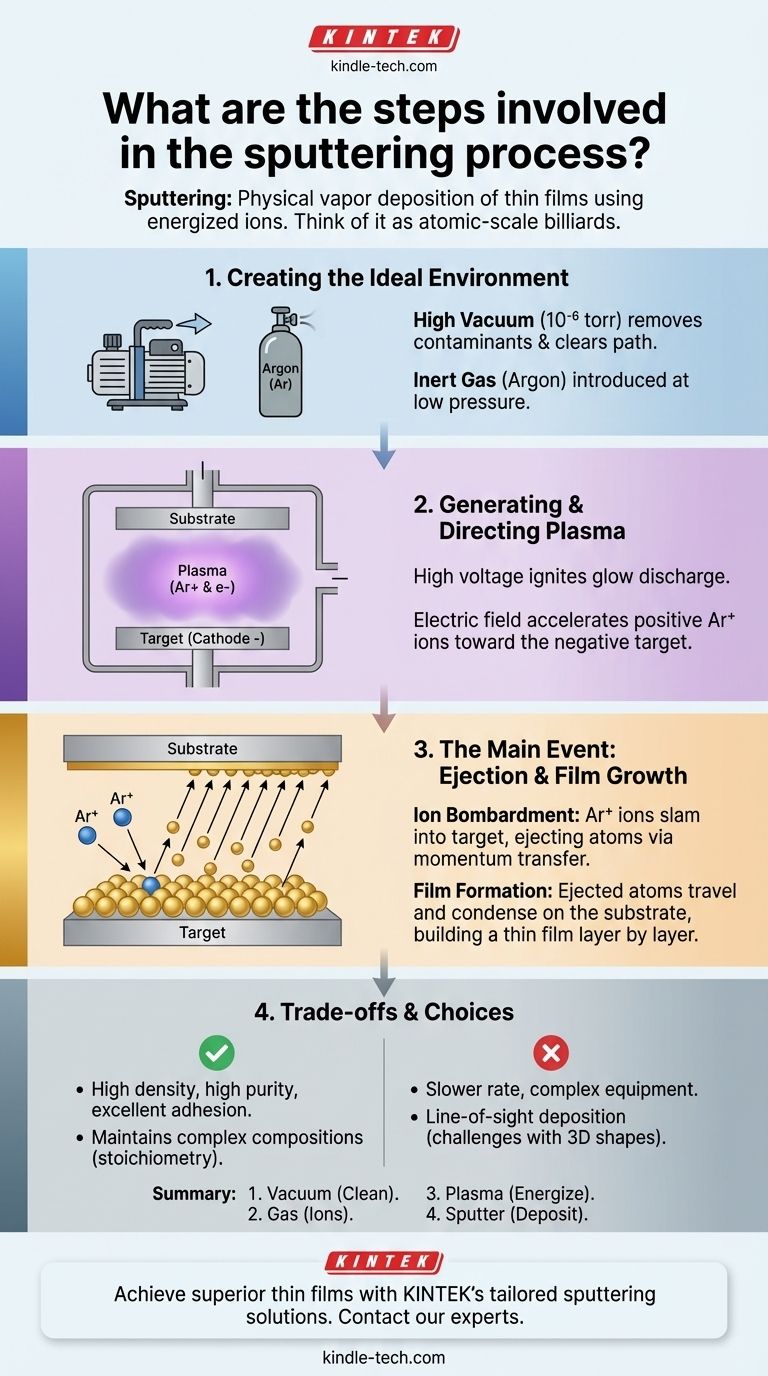

The Foundational Step: Creating the Ideal Environment

Before any deposition can occur, the system must be meticulously prepared. The environment inside the sputtering chamber dictates the purity and quality of the final film.

The Critical Role of the Vacuum

The entire process begins by creating a high vacuum inside a sealed deposition chamber, pumping out air and residual gases to a very low pressure (often 10⁻⁶ torr or lower). This base vacuum is non-negotiable for two reasons:

- Purity: It removes contaminants like oxygen, nitrogen, and water vapor that would otherwise react with the sputtered material and ruin the film's properties.

- Clear Path: It ensures the ejected target atoms have an unobstructed path to the substrate, preventing them from colliding with air molecules.

Introducing the Process Gas

Once a high vacuum is achieved, a small, precisely controlled amount of a high-purity inert gas is introduced into the chamber. Argon (Ar) is the most common choice.

This gas raises the chamber pressure slightly to a specific working pressure. The Argon atoms are not there to react with anything; they will become the projectiles that drive the entire process.

The Engine: Generating and Directing Plasma

With the environment set, the next stage is to create the energetic conditions necessary to eject material from the target.

Igniting the Plasma

A high voltage is applied across two electrodes within the chamber. The source material, or target, acts as the negatively charged electrode (the cathode).

This strong electric field energizes the chamber, stripping electrons from some of the Argon atoms. This creates a plasma, a distinctive glowing cloud composed of positively charged Argon ions (Ar+) and free electrons. This state is often called a "glow discharge."

Accelerating the Ions

Because the target is negatively charged (cathode) and the Argon ions (Ar+) are positively charged, the ions are powerfully accelerated directly toward the face of the target by the electric field. Magnetic fields are also often used to confine the plasma near the target, increasing the efficiency of this bombardment.

The Main Event: Ejection and Film Growth

This final stage is where the physical deposition happens, transforming a solid target material into a thin film, one atom at a time.

The Collision and Momentum Transfer

The high-energy Argon ions slam into the surface of the target. This is not a chemical reaction but a pure momentum transfer. The impact force is sufficient to dislodge or "sputter" individual atoms from the target material, ejecting them out into the vacuum chamber.

Deposition and Film Formation

The sputtered atoms travel in a straight line from the target until they strike a surface. By strategically placing a component, or substrate, in their path, these atoms land and condense on it.

Over time, this atomic deposition builds up, layer by layer, to form a thin, dense, and highly uniform film on the substrate's surface.

Understanding the Trade-offs

Sputtering is a powerful technique, but its application requires understanding its inherent characteristics and limitations.

Rate vs. Quality

Sputtering is generally a slower deposition method compared to techniques like thermal evaporation. Increasing power can speed up the process, but this can also introduce excess heat and potentially affect the film's structure and quality.

Process Complexity

The requirement for high-vacuum systems, high-voltage power supplies, and precise gas flow control makes sputtering equipment more complex and expensive than some alternatives. The process requires careful calibration to achieve repeatable results.

Line-of-Sight Deposition

Because sputtered atoms travel in straight lines, the process is considered "line-of-sight." This can make it challenging to uniformly coat complex, three-dimensional shapes without sophisticated substrate rotation and manipulation.

Making the Right Choice for Your Goal

The decision to use sputtering depends entirely on the desired properties of the final film.

- If your primary focus is a dense, high-purity, and high-adhesion film: Sputtering is an exceptional choice, as the energetic deposition process creates superior film density and bonding to the substrate.

- If your primary focus is coating a complex alloy or compound: Sputtering excels at maintaining the original material's composition (stoichiometry) from the target to the film.

- If your primary focus is simple, rapid coating for a non-critical application: A less complex method like thermal evaporation might be a more cost-effective solution.

Understanding these fundamental steps empowers you to leverage sputtering's precision for creating advanced, high-performance thin films.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Vacuum Creation | Pump chamber to high vacuum (e.g., 10⁻⁶ torr) | Remove contaminants, ensure clear path for atoms |

| 2. Gas Introduction | Add inert gas (e.g., Argon) at controlled pressure | Provide ions for bombardment |

| 3. Plasma Generation | Apply high voltage to create glow discharge | Ionize gas to form energetic Ar+ ions |

| 4. Sputtering & Deposition | Ions bombard target, ejecting atoms onto substrate | Build uniform, dense thin film layer by layer |

Ready to achieve superior thin film results in your lab? Sputtering delivers high-purity, dense coatings with excellent adhesion—perfect for demanding R&D and production applications. KINTEK specializes in lab equipment and consumables, offering tailored sputtering solutions to meet your specific material and substrate needs. Contact our experts today to discuss how our systems can enhance your coating processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials