In essence, sputtering is a physical process that uses energized gas ions to chip atoms off a source material, which then travel and deposit as a thin film onto a destination surface. The entire operation takes place in a high-vacuum chamber, allowing for the precise creation of coatings with specific electrical or optical properties.

Sputtering is not a chemical reaction or a simple melting process. It is best understood as a highly controlled, atomic-scale sandblasting where individual atoms are physically ejected from a target by momentum transfer and redeposited onto a substrate to form a new layer.

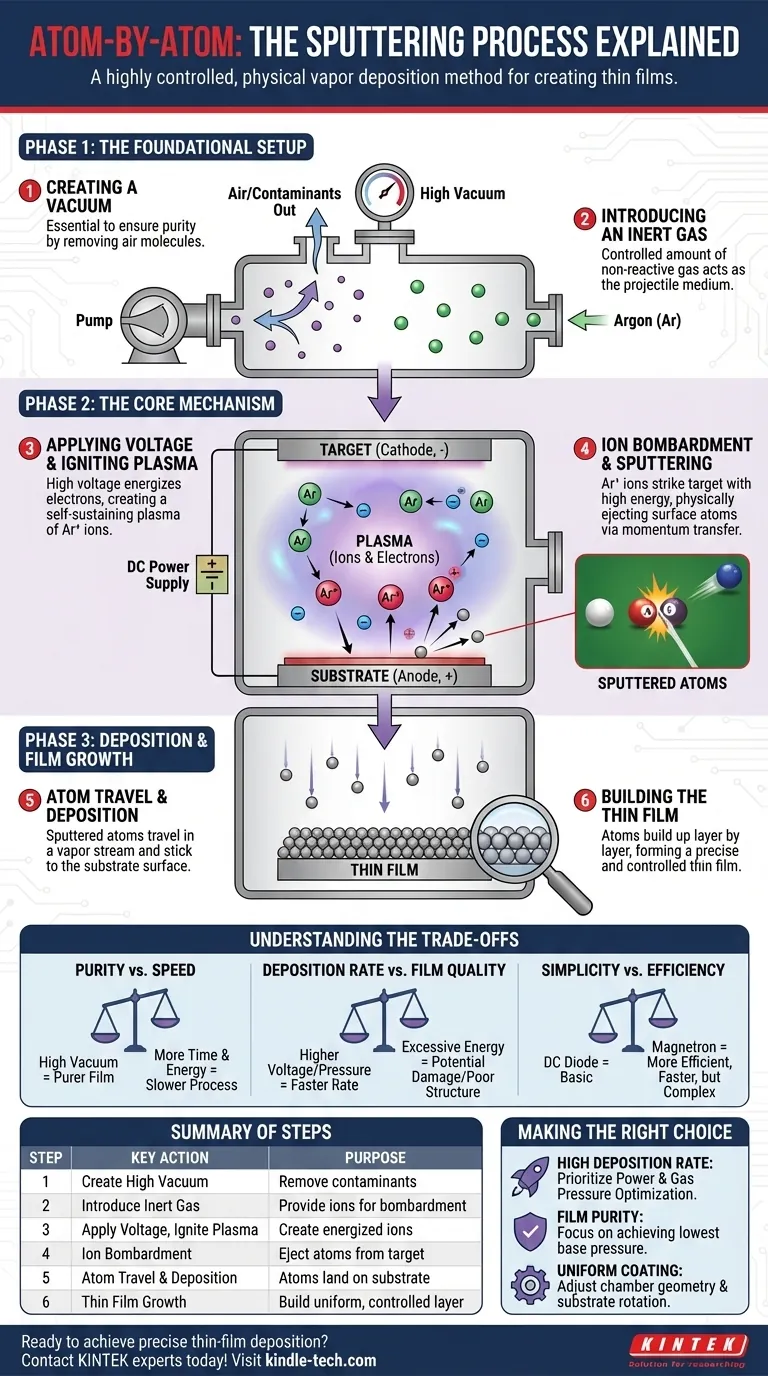

The Foundational Setup: The Vacuum Environment

Before any sputtering can occur, the environment must be meticulously prepared. This setup is critical for ensuring the purity and quality of the final film.

Step 1: Creating a Vacuum

The process begins by placing the source material, called the target, and the surface to be coated, the substrate, inside a sealed chamber. This chamber is then pumped down to a high vacuum.

This vacuum is essential because it removes air and other unwanted particles. Without it, the sputtered atoms would collide with air molecules, preventing them from reaching the substrate cleanly.

Step 2: Introducing an Inert Gas

Once a vacuum is established, a small, controlled amount of an inert gas is introduced into the chamber. Argon is the most common choice.

This gas does not react chemically with the materials. Instead, its atoms will be used as the "projectiles" to bombard the target material.

The Core Mechanism: Plasma and Ion Bombardment

With the stage set, the central action of the process begins. This is where the inert gas is transformed into an energetic tool for ejecting atoms from the target.

Step 3: Applying Voltage and Igniting a Plasma

A high voltage is applied between the target and the substrate, with the target acting as the negative electrode (cathode).

This voltage energizes free electrons in the chamber, causing them to collide with the argon gas atoms. These collisions are energetic enough to knock electrons off the argon atoms, creating two new particles: a positively charged argon ion (Ar+) and another free electron.

This process cascades, rapidly creating a self-sustaining, glowing cloud of ions and electrons known as a plasma.

Step 4: The "Sputtering" Event

The positive argon ions within the plasma are now strongly attracted to the negatively charged target. They accelerate across the chamber and strike the target surface with significant kinetic energy.

This impact sets off a "collision cascade" within the target material, similar to a cue ball breaking a rack of billiard balls. The momentum transfer from the incoming ion dislodges atoms from the target's surface.

These ejected atoms are what we call "sputtered."

The Final Stage: Deposition and Film Growth

The ejected atoms from the target now travel through the vacuum chamber and complete the process by forming a new layer on the substrate.

Step 5: Deposition on the Substrate

The sputtered atoms travel in a vapor stream until they strike the substrate. Upon arrival, they stick to the surface.

Step 6: Building the Thin Film

As this bombardment continues, millions of atoms are ejected from the target and land on the substrate every second. They build up, layer by layer, to form a highly uniform and controlled thin film.

The process allows for precise control over the film's thickness, density, and other characteristics by managing variables like gas pressure and electrical power.

Understanding the Trade-offs and Variables

The sputtering process is not a single, fixed recipe. The outcome is highly dependent on several interconnected factors, and optimizing one often requires compromising on another.

Purity vs. Speed

A higher vacuum level (fewer contaminant particles) ensures a purer deposited film. However, achieving and maintaining a very high vacuum takes more time and energy, slowing down the overall process.

Deposition Rate vs. Film Quality

Increasing the voltage or gas pressure can accelerate the sputtering rate, depositing the film faster. However, excessively high energy can sometimes damage the substrate or create a film with less-than-ideal structural properties.

Simplicity vs. Efficiency

The basic sputtering process described is known as DC diode sputtering. More advanced techniques, like magnetron sputtering, use magnets to trap electrons near the target. This significantly increases the ionization of the argon gas, leading to a much more efficient and faster deposition process, but it adds complexity to the system.

Making the Right Choice for Your Goal

Controlling the sputtering process allows you to engineer materials for specific applications. Your primary objective will determine which parameters you need to prioritize.

- If your primary focus is a high deposition rate: You should prioritize increasing the power applied to the target and optimizing the argon gas pressure to maximize the density of the plasma.

- If your primary focus is film purity: Your main concern should be achieving the lowest possible base pressure in the vacuum chamber before introducing the argon gas.

- If your primary focus is coating a complex shape uniformly: You will need to focus on the physical arrangement of the chamber, such as the distance between the target and substrate and implementing substrate rotation.

By understanding these fundamental steps, you can control a process that builds materials one atom at a time.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Create High Vacuum | Remove contaminants for a pure deposition environment |

| 2 | Introduce Inert Gas (Argon) | Provide ions to bombard the target material |

| 3 | Apply Voltage, Ignite Plasma | Create energized ions for the sputtering event |

| 4 | Ion Bombardment of Target | Eject atoms from the source material |

| 5 | Atom Travel & Deposition | Sputtered atoms land on the substrate surface |

| 6 | Thin Film Growth | Build uniform, controlled layer for specific properties |

Ready to achieve precise thin-film deposition in your lab? KINTEK specializes in high-quality sputtering equipment and consumables, serving all your laboratory coating needs. Whether your priority is high deposition rates, ultimate film purity, or uniform coating of complex shapes, our expertise ensures you get the right solution for your application. Contact our experts today to discuss how our sputtering systems can enhance your research and development!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing