When selecting a dental ceramic, the strongest material available is zirconia, while the toughest and most well-rounded option for many applications is lithium disilicate. Zirconia offers the highest resistance to fracture under load, making it ideal for high-stress situations. Lithium disilicate provides a superior balance of high strength, excellent durability, and natural-looking esthetics, making it a versatile workhorse for single-tooth restorations.

The strongest dental ceramic, zirconia, is not always the most suitable choice. The optimal material selection depends on a critical trade-off between absolute flexural strength (resisting biting forces), fracture toughness (resisting crack growth), and the esthetic requirements of the specific restoration.

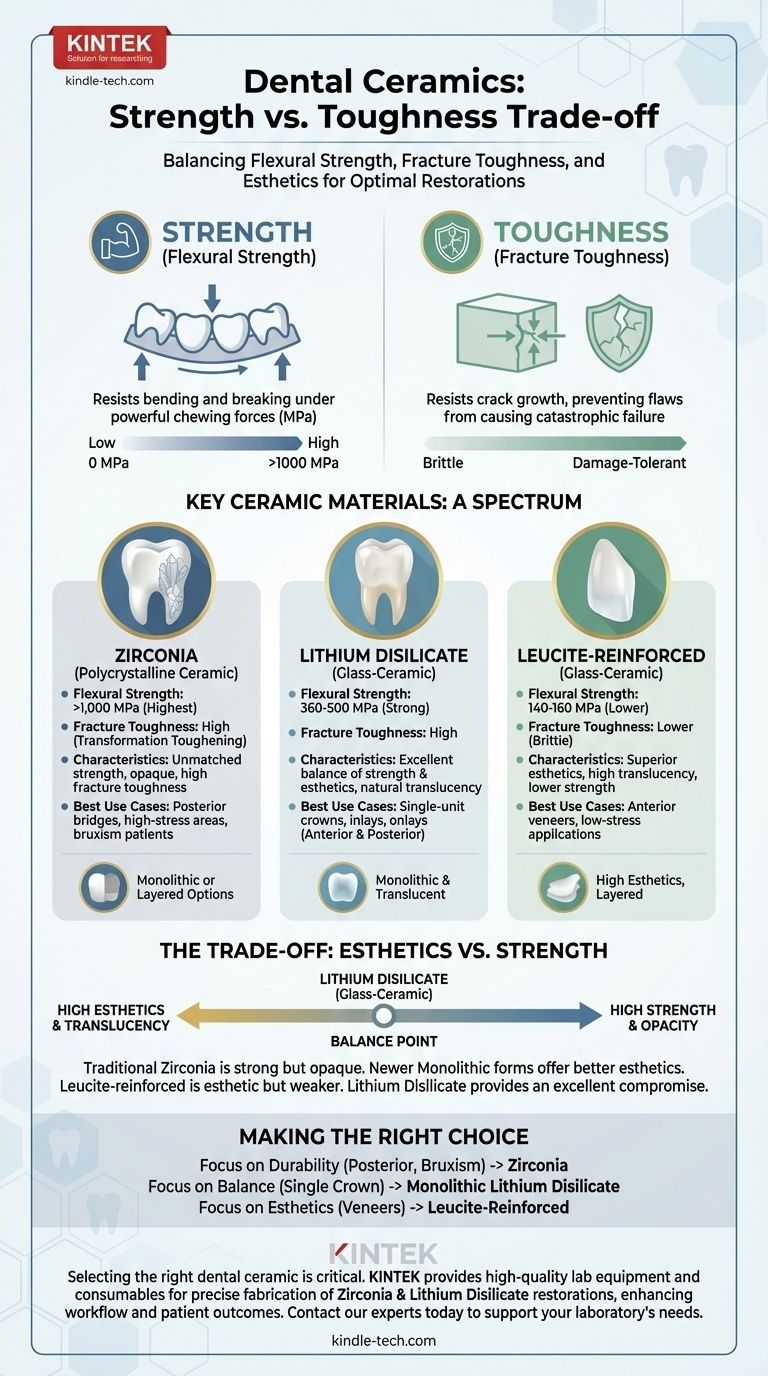

The Two Pillars of Durability: Strength vs. Toughness

To make an informed decision, it's essential to understand the two distinct mechanical properties that define a ceramic's durability. They are not interchangeable.

Defining Flexural Strength

Flexural strength measures a material's ability to resist bending before it breaks. It is typically measured in megapascals (MPa).

This is a critical indicator of how a crown or bridge will withstand the powerful forces of chewing (mastication), especially in the posterior region of the mouth.

Defining Fracture Toughness

Fracture toughness measures a material's ability to resist the propagation of a crack once a flaw already exists.

This property is arguably more important for long-term clinical survival. Micro-cracks can form during manufacturing or from chewing, and a tough material will prevent these small flaws from growing into a catastrophic fracture.

Why This Distinction Matters in Dentistry

A material can have very high flexural strength but be brittle (low fracture toughness). It might withstand immense force but shatter completely from a tiny, focused impact or pre-existing flaw.

Conversely, a tougher material is more forgiving and damage-tolerant, ensuring greater longevity even if it doesn't have the highest absolute strength value.

A Breakdown of Key Ceramic Materials

Modern dental ceramics fall on a spectrum from high-strength and opaque to high-esthetic and more translucent.

Zirconia: The Benchmark for Strength

Zirconia is a polycrystalline ceramic, meaning it has a tightly packed crystalline structure with no glass phase. This gives it the highest mechanical properties of any dental ceramic.

Its flexural strength can exceed 1,000 MPa, making it suitable for long-span bridges and restorations in patients with heavy biting forces.

Zirconia's high fracture toughness comes from a unique mechanism called transformation toughening. When a crack starts, the crystal structure around the crack tip expands, creating compressive forces that effectively stop the crack from advancing.

Lithium Disilicate: The All-Round Performer

Lithium disilicate is a glass-ceramic known for its exceptional balance of properties. It is widely used for single-unit crowns, inlays, and onlays.

With a flexural strength typically in the 360-500 MPa range, it is significantly stronger than older glass-ceramics and strong enough for most situations.

Its primary advantage is its combination of high strength with excellent esthetics. The glass matrix allows for natural-looking translucency that can perfectly mimic tooth enamel.

Leucite-Reinforced Glass-Ceramics: The Esthetic Option

Leucite-reinforced ceramics were among the first truly esthetic, all-ceramic options. They contain leucite crystals within a glass matrix to improve strength.

Their flexural strength is lower, generally around 140-160 MPa.

Because of their lower strength, their use is now primarily limited to low-stress applications where appearance is the top priority, such as anterior veneers.

Understanding the Trade-offs: Esthetics vs. Strength

The choice of material almost always involves balancing mechanical needs with visual demands.

The Opacity Challenge of Zirconia

Traditional, high-strength zirconia is very opaque due to its dense crystalline structure. This can result in a chalky, unnatural look if not masked.

To overcome this, dentists often use a "layered" zirconia crown, where a zirconia core is covered with a more esthetic porcelain. However, this veneering porcelain is the weak link and can chip.

The "Monolithic" Solution

Recent advancements have produced more translucent forms of zirconia (e.g., "5Y" or cubic zirconia) and reinforced lithium disilicate.

These materials can be used in their full-contour, "monolithic" form without layering. This eliminates the risk of chipping and combines excellent strength with very good esthetics, representing the best of both worlds for many clinical cases.

Making the Right Choice for Your Restoration

Your final decision should be guided by the specific functional and esthetic demands of the case.

- If your primary focus is maximum durability for a posterior bridge or for a patient with bruxism: Zirconia is the material of choice due to its unmatched flexural strength and fracture toughness.

- If your primary focus is a balance of high strength and excellent esthetics for a single crown (anterior or posterior): Monolithic lithium disilicate provides a reliable and beautiful outcome that is often indistinguishable from a natural tooth.

- If your primary focus is the highest possible esthetics in a low-stress area like a veneer: Leucite-reinforced or other feldspathic ceramics offer superb optical properties, though with significantly lower mechanical strength.

Understanding the distinct properties of strength, toughness, and esthetics allows you to select the ideal ceramic for a predictable and lasting clinical result.

Summary Table:

| Material | Flexural Strength | Fracture Toughness | Key Characteristics | Best Use Cases |

|---|---|---|---|---|

| Zirconia | > 1,000 MPa | High (Transformation Toughening) | Unmatched strength, opaque, monolithic or layered | Posterior bridges, high-stress areas, patients with bruxism |

| Lithium Disilicate | 360-500 MPa | High | Excellent strength/esthetics balance, monolithic | Single-unit crowns, inlays, onlays (anterior & posterior) |

| Leucite-Reinforced | 140-160 MPa | Lower | Superior esthetics, lower strength | Anterior veneers, low-stress applications |

Selecting the right dental ceramic is critical for a durable, long-lasting restoration. KINTEK specializes in providing high-quality lab equipment and consumables for dental laboratories, ensuring precise fabrication of zirconia and lithium disilicate restorations. Our solutions help you achieve optimal material performance and esthetic results for your patients. Contact our experts today to discuss how we can support your laboratory's specific needs and enhance your workflow efficiency.

Visual Guide

Related Products

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Electrode Polishing Material for Electrochemical Experiments

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is in a dental laboratory? Discover the High-Tech Hub Creating Your Perfect Smile

- What are some features found in many modern dental ovens? Enhancing Precision Through Digital Integration

- What type of zirconia has better esthetics? Choose High-Translucency 4Y/5Y Zirconia for Superior Beauty

- In what contexts is a slow cooling protocol important for dental restorations? Ensure Durability with Precise Thermal Care

- What is the primary function of a Dental Press Furnace? Fabricate Strong, Aesthetic Dental Restorations

- How strong are ceramic implants? Discover the Power of Zirconia for a Metal-Free Smile

- What is the disadvantage of ceramic for implant? Understanding the Risk of Fracture and Long-Term Durability