The raw material, or feedstock, is the single most critical factor determining the final quality and characteristics of biochar. Broadly, feedstocks are classified into three main categories: woody biomass, agricultural residues, and other organic wastes. Each category contains a wide variety of materials that yield a biochar with unique properties.

While nearly any organic material can be converted into biochar, the choice of feedstock is a strategic decision. The physical and chemical properties of the raw material directly determine the resulting biochar's characteristics—such as pH, porosity, and nutrient content—defining its ultimate value and application.

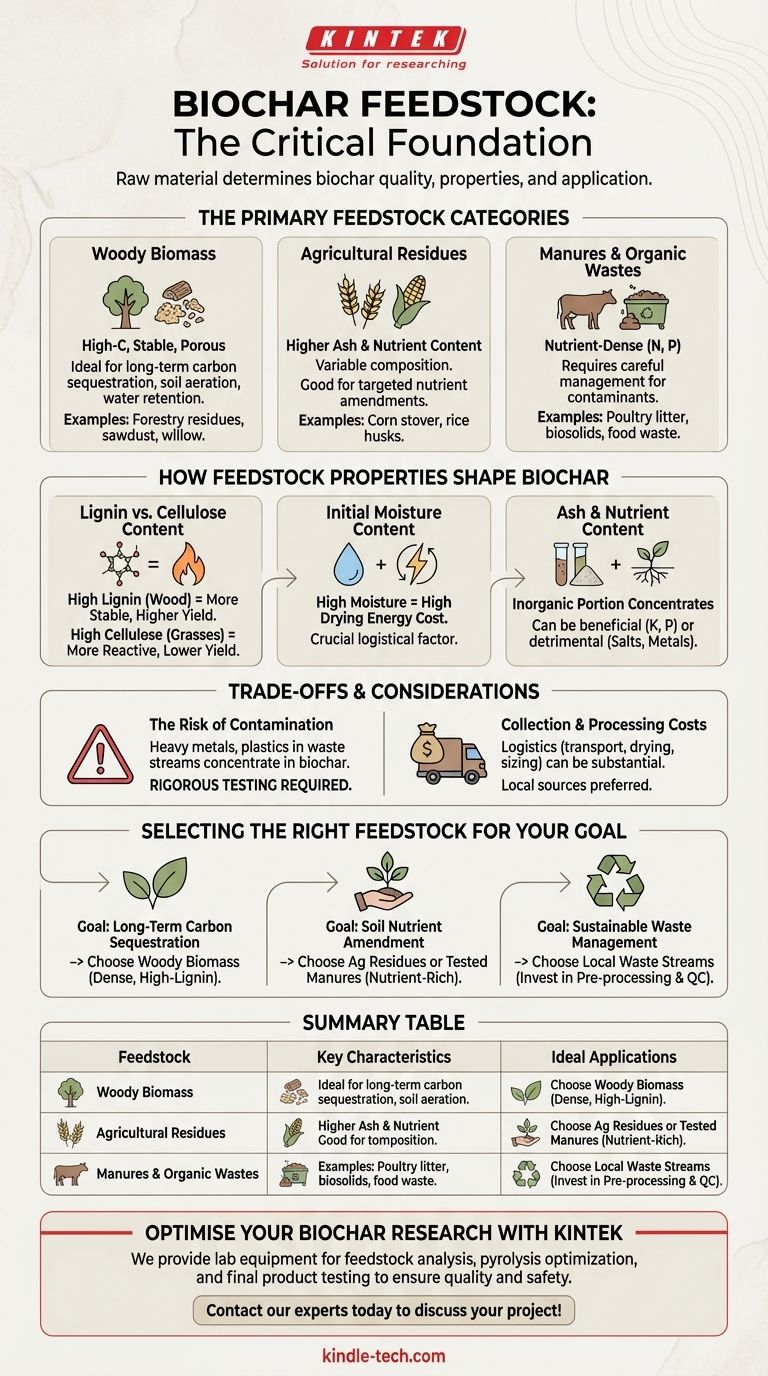

The Primary Feedstock Categories

Understanding the major types of feedstock is the first step in producing a biochar fit for a specific purpose. The source material dictates everything from the production process efficiency to the final product's performance.

Woody Biomass

This category includes materials derived from trees and woody plants. These feedstocks are generally high in lignin, a complex polymer that provides structural rigidity to plants.

Woody biomass typically produces a high-carbon, stable biochar with a porous structure. This makes it ideal for long-term carbon sequestration and for improving soil aeration and water retention. Common examples include forestry residues, wood chips, sawdust, and dedicated energy crops like willow.

Agricultural Residues

These are the leftover materials from crop harvesting and processing. Their composition is highly variable, depending on the specific crop.

Biochars from agricultural residues often have a higher ash and nutrient content compared to woody biomass. For example, rice husks produce a silica-rich biochar, while corn stover yields a biochar high in potassium. These are excellent for targeted nutrient amendments in soil.

Manures and Other Organic Wastes

This diverse category includes animal manures, poultry litter, biosolids from wastewater treatment, and food processing waste.

These feedstocks produce nutrient-dense biochars, rich in phosphorus and nitrogen. However, they require careful management as they can also concentrate salts and potential contaminants like heavy metals, demanding rigorous testing before use in agriculture.

How Feedstock Properties Shape Biochar

The specific characteristics of a raw material have a direct and predictable impact on the final biochar. Understanding these relationships is key to designing a successful biochar production system.

Lignin vs. Cellulose Content

Feedstocks high in lignin, like wood, are more resistant to thermal decomposition. This results in a higher biochar yield and creates a final product that is more stable and resistant to microbial breakdown in the soil.

Materials higher in cellulose and hemicellulose, like grasses and leaves, produce lower yields of a more reactive biochar.

Initial Moisture Content

Moisture content is a critical logistical factor. Feedstock with high moisture requires a significant amount of energy to drive off water before the core process of pyrolysis can even begin.

This "drying energy" can make or break the economic viability of a project. Sourcing dry feedstock or implementing an efficient drying process is essential.

Ash and Nutrient Content

The inorganic portion of the feedstock (minerals, salts, metals) does not burn off during pyrolysis. Instead, it becomes concentrated in the final biochar as ash.

High ash content can be beneficial if it contains valuable nutrients like potassium (K) and phosphorus (P). However, it can be detrimental if it consists of undesirable elements or raises soil salinity.

Understanding the Trade-offs and Contaminants

Choosing a feedstock is not just about its ideal properties but also about its practical limitations and potential risks. An objective assessment is crucial for a safe and effective outcome.

The Risk of Contamination

Not all organic waste is clean. Feedstocks sourced from industrial or municipal waste streams can contain contaminants like heavy metals, plastics, or persistent organic pollutants.

These contaminants are not destroyed by pyrolysis and can become concentrated in the biochar, posing a risk to soil health and food safety. Always test feedstocks from unknown or mixed sources.

Collection and Processing Costs

While a feedstock like agricultural residue or manure may seem "free," the costs associated with its collection, transportation, drying, and sizing can be substantial.

These logistical costs must be factored into the overall economic model. A locally abundant, consistent, and easy-to-handle feedstock is almost always preferable to a theoretically "better" but distant or complex one.

Selecting the Right Feedstock for Your Goal

Your end-use application should guide your feedstock selection. Tailoring the input material to the desired output is the most efficient path to success.

- If your primary focus is long-term carbon sequestration: Choose dense, high-lignin woody biomass to produce the most stable, high-carbon biochar possible.

- If your primary focus is soil nutrient amendment: Use agricultural residues or tested animal manures to create a biochar rich in specific plant-available nutrients like phosphorus and potassium.

- If your primary focus is sustainable waste management: Target locally abundant, low-cost waste streams, but invest heavily in pre-processing and quality control to ensure you produce a safe and valuable end product.

Ultimately, the best feedstock is one that is sustainable, cost-effective, and produces a biochar perfectly matched to your intended application.

Summary Table:

| Feedstock Category | Key Characteristics | Ideal Applications |

|---|---|---|

| Woody Biomass (wood chips, sawdust) | High lignin, stable, porous, high carbon content | Carbon sequestration, soil aeration, water retention |

| Agricultural Residues (corn stover, rice husks) | Higher ash & nutrient content, variable composition | Targeted soil nutrient amendment |

| Manures & Organic Wastes (poultry litter, biosolids) | Nutrient-dense (N, P), potential for contaminants | Waste management, nutrient amendment (with testing) |

Ready to produce high-quality biochar tailored to your specific goals?

At KINTEK, we specialize in laboratory equipment and consumables for advanced biochar research and production. Whether you're focused on carbon sequestration, soil health, or sustainable waste management, our solutions help you analyze feedstock properties, optimize pyrolysis conditions, and ensure final product quality.

We help you:

- Accurately characterize feedstock composition.

- Optimize pyrolysis processes for maximum yield and quality.

- Test for contaminants and ensure product safety.

Let's build the right solution for your lab's needs. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the advantages of pyrolysis and gasification? Choosing the Right Waste-to-Energy Technology

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the products of fast pyrolysis? Bio-Oil, Bio-Char, and Syngas Explained

- Why are industrial rotary furnaces utilized for hematite phase transformation? Optimize Your Ore Processing Today

- What is different between calcination? Unlocking Thermal Processing for Material Science

- What is a tilt furnace? A Guide to Safe, Controlled Melting and Pouring

- What is the temperature and time for slow pyrolysis? Optimize Your Biochar Production Process

- What is pyrolysis and the process of pyrolysis? Turn Waste into Valuable Resources