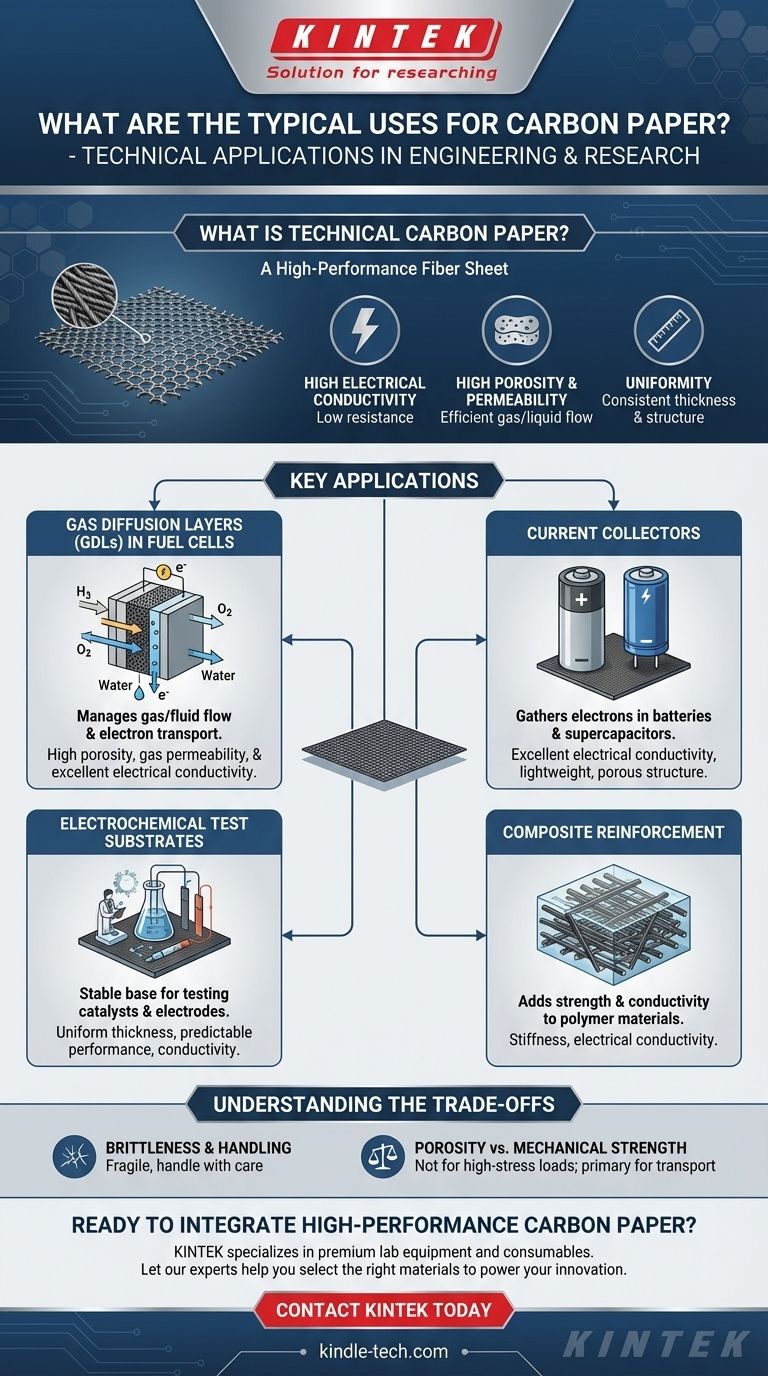

In modern engineering and research, technical carbon paper is a high-performance material used as a current collector in batteries, a reinforcement for composite materials, and a substrate for electrochemical testing. Its most critical role, however, is serving as the Gas Diffusion Layer (GDL) in advanced fuel cells, a function completely distinct from the historical paper used for making copies.

Carbon paper’s value comes from a unique combination of properties: it is highly porous, permeable to gas, and an excellent electrical conductor. These traits make it the ideal material for applications that require the controlled movement of gases, fluids, and electrons across a thin, stable plane.

What is Technical Carbon Paper?

A High-Performance Fiber Sheet

Unlike its name might suggest, technical carbon paper is not a paper product for writing or copying. It is a thin, sheet-like material engineered from carbon fibers that have been bonded and pressed together.

This process results in a material with a uniform thickness and a highly porous internal structure.

The Properties That Define It

The utility of carbon paper is rooted in several key characteristics:

- High Electrical Conductivity: As it's made from carbon, the material allows electricity to pass through it with very little resistance.

- High Porosity & Permeability: It contains a network of tiny, interconnected voids. This allows gases and liquids to flow through it efficiently.

- Uniformity: It is manufactured to have a consistent thickness and structure, which is critical for predictable performance in sensitive applications.

Key Applications Explained

Gas Diffusion Layers (GDLs) in Fuel Cells

This is one of the most common and critical uses for carbon paper. In a fuel cell, the GDL is essential for managing the flow of reactants and products.

Carbon paper's high porosity and gas permeability allow fuel (like hydrogen) to travel to the catalyst layer while allowing byproducts (like water) to exit. Simultaneously, its excellent electrical conductivity collects the electrons generated by the electrochemical reaction, moving them into the external circuit.

Current Collectors

In devices like batteries and supercapacitors, a current collector is needed to gather electrons from the active material and guide them out of the device.

Carbon paper serves as a lightweight, flexible, and highly conductive substrate for this purpose. Its porous structure can also help the active material adhere to its surface.

Electrochemical Test Substrates

When researchers develop new catalysts or electrode materials, they need a stable, conductive, and predictable base to test them on.

Carbon paper is an excellent choice for these substrates because its uniform thickness and well-understood properties ensure that experimental results are reliable and reproducible.

Reinforcement in Composite Materials

Carbon paper can be embedded within a polymer matrix to create a composite material. This leverages the inherent strength and stiffness of carbon fibers.

Furthermore, it imparts electrical conductivity to the entire composite, which can be useful for applications requiring static dissipation or integrated electronic functionality.

Understanding the Trade-offs

Brittleness and Handling

A primary limitation of carbon paper is its brittle texture. The material can be fragile and must be handled with care to prevent cracking or flaking.

This brittleness can present challenges during the manufacturing and assembly of devices, requiring specialized processes to avoid damaging the paper.

Porosity vs. Mechanical Strength

The high porosity that makes carbon paper so effective as a GDL is inherently a trade-off against mechanical strength.

While strong for its weight, it is not designed for high-stress structural loads. Its primary function is transport (of gases and electrons), not mechanical support.

How to Apply This to Your Project

Understanding these applications allows you to select carbon paper for the right task.

- If your primary focus is fuel cell or electrolyzer development: You will use carbon paper as a Gas Diffusion Layer to manage gas flow and electron transport.

- If your primary focus is battery or supercapacitor research: It is an ideal candidate for a lightweight, high-surface-area current collector.

- If your primary focus is fundamental electrochemistry: It serves as a reliable and uniform substrate for building and testing novel electrodes.

- If your primary focus is creating advanced materials: You can incorporate it into a polymer to develop a custom conductive composite.

Ultimately, recognizing that carbon paper is a platform for transport is the key to leveraging its capabilities in any advanced technical project.

Summary Table:

| Application | Key Function | Key Properties Utilized |

|---|---|---|

| Gas Diffusion Layer (GDL) | Manages gas/fluid flow & electron transport in fuel cells | High porosity, gas permeability, electrical conductivity |

| Current Collector | Gathers electrons in batteries & supercapacitors | Excellent electrical conductivity, lightweight, porous structure |

| Electrochemical Substrate | Provides a stable base for testing catalysts & electrodes | Uniform thickness, predictable performance, conductivity |

| Composite Reinforcement | Adds strength & conductivity to polymer materials | Stiffness, electrical conductivity |

Ready to integrate high-performance carbon paper into your lab's workflow?

KINTEK specializes in providing premium lab equipment and consumables, including technical carbon paper ideal for fuel cell research, battery development, and electrochemical testing. Our materials ensure the reliability and reproducibility your projects demand.

Let our experts help you select the right materials to power your innovation.

Contact KINTEK today to discuss your specific application needs!

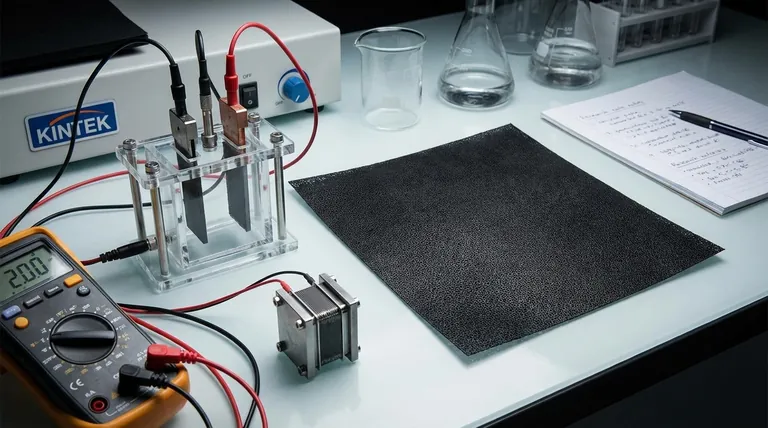

Visual Guide

Related Products

- Aluminum Foil Current Collector for Lithium Battery

- Electrolytic Electrochemical Cell for Coating Evaluation

- Copper Nickel Foam Metal Sheet

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- How is plastic waste different from other types of waste? The Hidden Threat of Microplastics

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- How do you test the capacity of a lithium-ion battery? A Guide to Accurate Measurement

- How to check the power of a lithium-ion battery? Master the difference between charge level and battery health.

- What are two disadvantages of metal? Understanding Corrosion and Weight Limitations