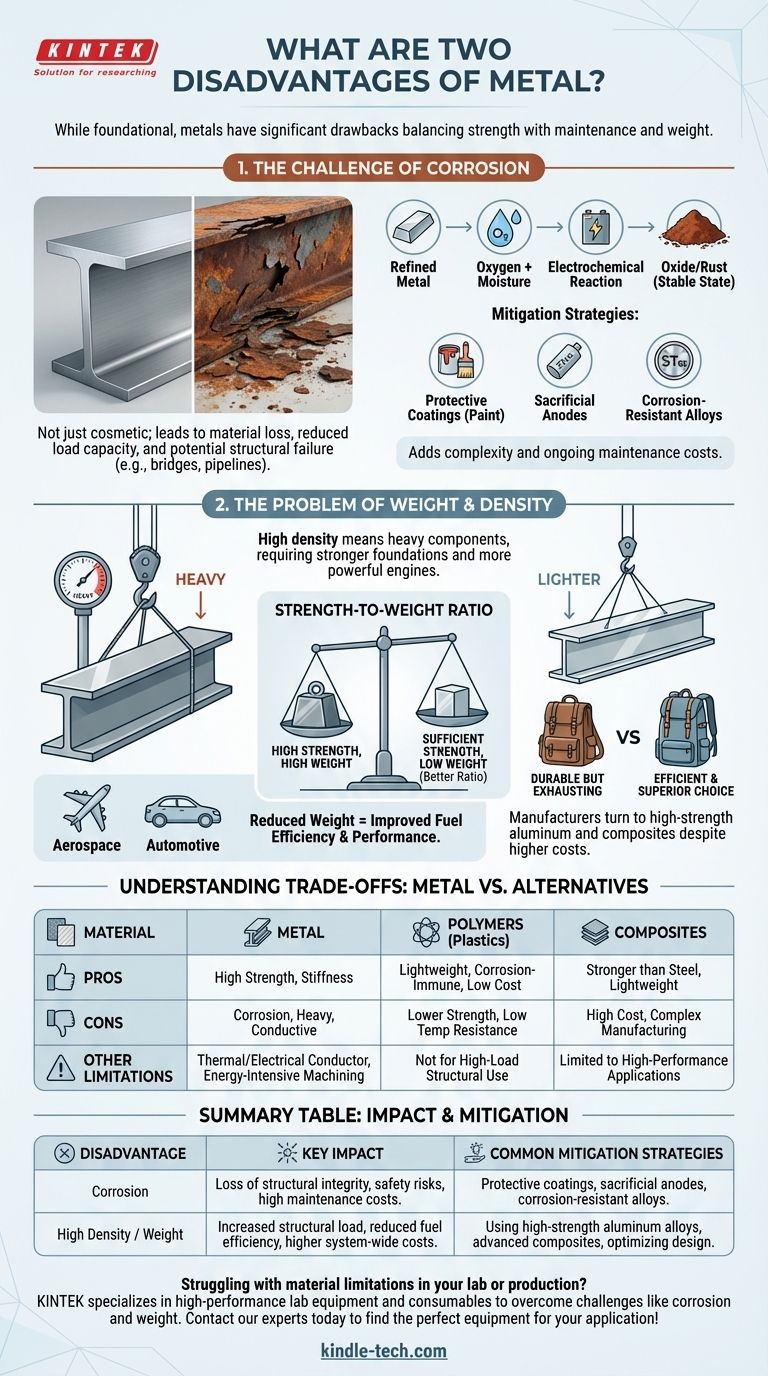

While foundational to modern engineering, metals are not without significant drawbacks. The two most prominent disadvantages are their susceptibility to corrosion, such as rust, and their characteristically high density, which results in heavy components. These limitations force engineers to constantly balance the benefits of strength against the long-term costs of maintenance and the physical burden of weight.

The perceived strength of metal often overshadows its practical limitations. The most critical takeaway is that material selection is never about finding a perfect material, but about choosing the one whose disadvantages you can best tolerate or mitigate for a specific application.

The Challenge of Corrosion

Corrosion is arguably the most persistent and costly disadvantage of using many common metals, particularly steel.

What is Corrosion?

Corrosion is a natural process where a refined metal attempts to revert to a more stable chemical state, typically an oxide. For iron and steel, this process is called rusting.

This electrochemical reaction is accelerated by exposure to oxygen and moisture, which are present in most operating environments.

The Structural Impact

Corrosion is not merely a cosmetic issue. As the metal oxidizes, it loses material, leading to a reduction in its cross-sectional area and, consequently, its load-bearing capacity.

This gradual weakening can lead to catastrophic structural failure if not managed, posing significant safety risks in bridges, pipelines, and vehicles.

Mitigation is a Constant Cost

Engineers must actively design against corrosion. This involves applying protective coatings like paint, using sacrificial anodes, or specifying more expensive, corrosion-resistant alloys like stainless steel or aluminum.

These mitigation strategies add complexity, cost, and ongoing maintenance requirements to any project involving susceptible metals.

The Problem of Weight and Density

The inherent strength of metal comes with a significant penalty: weight. Metals are dense materials, and this creates major engineering hurdles.

Density vs. Strength

While a steel I-beam is incredibly strong, it is also incredibly heavy. In many applications, the weight of the structure itself constitutes a major portion of the total load it must support.

This high density means more substantial foundations are required for buildings and more powerful engines are needed for vehicles, adding to system-wide costs.

The Importance of Strength-to-Weight Ratio

The critical metric in many modern applications is the strength-to-weight ratio. This measures how strong a material is for its weight.

Think of it like choosing a backpack for a long hike. A heavy-duty leather pack might be indestructible, but its own weight will exhaust you. A modern nylon pack, while less durable in absolute terms, offers more than enough strength at a fraction of the weight, making it the superior choice for the task.

Real-World Consequences

This principle is paramount in the aerospace and automotive industries. Reducing a vehicle's weight directly improves fuel efficiency and performance.

This is why manufacturers increasingly turn to high-strength aluminum alloys and carbon-fiber composites, even though they can be more expensive than traditional steel. The weight savings justify the cost.

Understanding the Trade-offs: Metal vs. Alternatives

The disadvantages of metal become clear when compared to other material classes. No material is perfect; each represents a different set of compromises.

The Case for Polymers (Plastics)

Polymers are lightweight, immune to corrosion, and can be easily molded into complex shapes at a low cost.

However, they generally lack the strength, stiffness, and high-temperature resistance of metals, making them unsuitable for high-load structural applications.

The Rise of Composites

Composites, like carbon fiber, offer the best of both worlds: they can be stronger than steel at a fraction of the weight.

Their primary disadvantage is immense cost and complex manufacturing processes, which currently limit their use to high-performance applications like race cars and aircraft.

Other Metal-Specific Limitations

Beyond corrosion and weight, metals are excellent thermal and electrical conductors. While useful for a heatsink or a wire, this property is a disadvantage for applications requiring insulation.

Furthermore, machining and welding metals to create final parts is an energy-intensive and often expensive process compared to molding plastics.

Making the Right Material Choice

Your decision should be guided by the non-negotiable requirements of your project. The ideal material is the one whose properties align with your primary goal.

- If your primary focus is maximum strength and structural rigidity: Ferrous metals like steel are often the best choice, but you must design and budget for corrosion mitigation from the start.

- If your primary focus is minimizing weight for performance or portability: High-strength aluminum alloys or advanced composites are superior, as the reduction in mass is the most critical factor.

- If your primary focus is complex shapes, cost-effectiveness in high volume, and environmental resistance: Polymers are often the ideal solution, provided the mechanical and thermal loads are within their limits.

Understanding a material's weaknesses is the true key to leveraging its strengths effectively.

Summary Table:

| Disadvantage | Key Impact | Common Mitigation Strategies |

|---|---|---|

| Corrosion | Loss of structural integrity, safety risks, high maintenance costs. | Protective coatings, sacrificial anodes, corrosion-resistant alloys (e.g., stainless steel). |

| High Density / Weight | Increased structural load, reduced fuel efficiency, higher system-wide costs. | Using high-strength aluminum alloys, advanced composites, optimizing design for strength-to-weight ratio. |

Struggling with material limitations in your lab or production process? The right equipment is key to overcoming challenges like corrosion and weight. KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories and research facilities. Whether you need corrosion-resistant components or tools for working with advanced lightweight materials, we have the solutions to enhance your efficiency and results. Contact our experts today to find the perfect equipment for your application!

Visual Guide

Related Products

- Metal Disc Electrode Electrochemical Electrode

- High Purity Gold Platinum Copper Iron Metal Sheets

- Lab-Scale Vacuum Induction Melting Furnace

- Platinum Sheet Electrode for Battery Lab Applications

- Nickel Foam for Industrial and Laboratory Applications

People Also Ask

- How does gold sputter coating work? Achieve Ultra-Thin, Conductive Films for SEM

- What are the safety considerations for titanium? From Biocompatible Metal to Fire Hazard

- How does a high-power ultrasonic homogenizer assist in the preparation of organic-inorganic nanocomposites?

- How is plastic waste different from other types of waste? The Hidden Threat of Microplastics

- What are the recommendations for proper plate filter press operation? Achieve Maximum Efficiency and Dry Cake

- What products are made from sintering? High-Strength Parts for Automotive, Dental & Industrial Use

- What is the cost for biomass energy? Understanding the $0.06-$0.15/kWh Range and Key Drivers

- What are the safety precautions for brazing? Protect Yourself from Heat, Fumes, and Fire