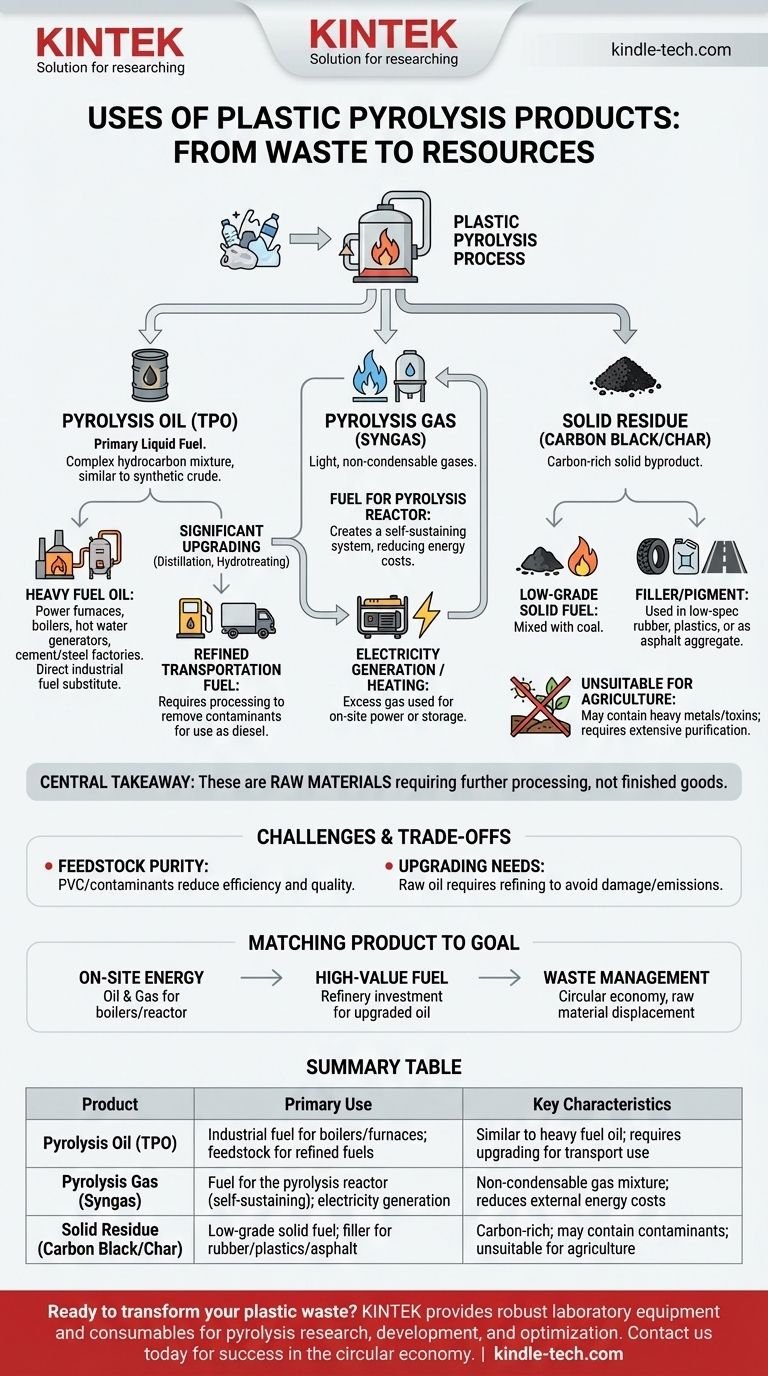

At its core, plastic pyrolysis is a thermal decomposition process that breaks down plastic waste into three primary products: a liquid fuel known as pyrolysis oil, a non-condensable pyrolysis gas, and a solid residue called carbon black or char. Each of these outputs has distinct industrial and commercial uses, primarily centered on energy generation and raw material recovery.

The central takeaway is that while plastic pyrolysis successfully converts waste into valuable energy products, these outputs are not finished goods. They are raw materials that almost always require further processing, cleaning, or refining to be used in higher-value applications like transportation fuels.

Deconstructing the Outputs of Plastic Pyrolysis

The viability of a plastic pyrolysis operation hinges on finding a market or use for each of its three output streams. The quality and specific characteristics of these products are highly dependent on the type and purity of the plastic feedstock used.

Pyrolysis Oil (TPO): The Primary Liquid Fuel

The most valuable product by volume is typically the liquid oil, often called Tire Pyrolysis Oil (TPO) when derived from tires or simply plastic pyrolysis oil. It is a complex mixture of hydrocarbons, similar in some ways to a synthetic crude oil.

Its most direct application is as a heavy fuel oil for industrial purposes. It can be used to power furnaces, boilers, hot water generators, and cement or steel factories. It serves as a direct substitute for conventional industrial fuels.

To be used as a more refined transportation fuel, such as diesel, the raw pyrolysis oil must undergo significant upgrading. This involves processes like distillation to separate different fuel fractions and hydrotreating to remove sulfur, nitrogen, and other contaminants.

Pyrolysis Gas (Syngas): Powering the Process

During pyrolysis, a certain percentage of the hydrocarbons are broken down into light, non-condensable gases. This mixture is often called "syngas."

The most common and efficient use for this gas is to fuel the pyrolysis reactor itself. It is redirected back to the burners that heat the chamber, creating a self-sustaining system that significantly reduces external energy costs.

Any excess gas not used for heating can be used to generate electricity with a gas generator or be stored for other heating applications on-site.

Solid Residue (Carbon Black/Char): The Solid Byproduct

After the volatile components have been vaporized, a solid, carbon-rich residue remains. This is commonly referred to as carbon black, though its quality is typically lower than industrially produced carbon black.

Its primary use is as a low-grade solid fuel, often mixed with coal or other materials. It can also be used as a filler or pigment in manufacturing low-spec rubber, plastics, or as an aggregate in asphalt production.

Some sources refer to this as "bio-char," but this is misleading. Unlike biochar from wood, plastic-derived char can contain a high concentration of heavy metals and other toxic residues from the original plastic waste, making it unsuitable for agricultural use as a soil amendment without extensive purification and testing.

Understanding the Quality and Contamination Trade-offs

The promise of turning waste plastic into fuel is compelling, but the reality is governed by technical and chemical limitations. The value of the outputs is directly tied to their quality.

The Challenge of Feedstock Purity

The type of plastic waste used as feedstock is the single most important factor. For example, the presence of PVC plastic will introduce chlorine, leading to the formation of corrosive hydrochloric acid in the system and contaminating the final oil.

Similarly, contaminants like food waste, paper, and dirt will lower the efficiency of the process and can end up concentrated in the solid char residue.

The Need for Upgrading and Refining

Raw pyrolysis oil is not a "drop-in" replacement for diesel fuel. It is an intermediate feedstock. Without refining, its acidic nature, high viscosity, and impurities can damage standard engines and create harmful emissions.

Achieving high-value fuel requires a secondary investment in distillation and purification technology, which adds significant cost and complexity to the operation.

Environmental and Safety Considerations

Managing all outputs responsibly is critical. The wastewater generated from moist feedstock must be treated. The solid char, if not sold, must be disposed of correctly, as it may be classified as hazardous waste depending on its composition.

Matching the Product to Your Goal

The best application of pyrolysis products depends entirely on your strategic objective.

- If your primary focus is on-site energy generation: Use the pyrolysis oil directly in industrial boilers or furnaces and use the syngas to make the process self-sufficient.

- If your primary focus is producing high-value transportation fuel: Be prepared to invest in a secondary refinery system to distill, purify, and upgrade the raw pyrolysis oil.

- If your primary focus is waste management in a circular economy: View the oil and char as recovered raw materials that re-enter the industrial supply chain, displacing the need for virgin fossil fuels.

Plastic pyrolysis is a powerful chemical recycling tool, turning a problematic waste stream into a source of energy and raw materials when its outputs are managed with a clear understanding of their properties and limitations.

Summary Table:

| Product | Primary Use | Key Characteristics |

|---|---|---|

| Pyrolysis Oil (TPO) | Industrial fuel for boilers/furnaces; feedstock for refined fuels | Similar to heavy fuel oil; requires upgrading for transport use |

| Pyrolysis Gas (Syngas) | Fuel for the pyrolysis reactor (self-sustaining); electricity generation | Non-condensable gas mixture; reduces external energy costs |

| Solid Residue (Carbon Black/Char) | Low-grade solid fuel; filler for rubber/plastics/asphalt | Carbon-rich; may contain contaminants; unsuitable for agriculture |

Ready to transform your plastic waste into valuable resources? KINTEK specializes in providing robust laboratory equipment and consumables to help you research, develop, and optimize your pyrolysis processes. From analyzing feedstock purity to testing product quality, our solutions support your journey in sustainable material recovery. Contact us today to discuss how we can equip your lab for success in the circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the effect of pyrolysis? Converting Waste into Fuel, Chemicals, and Energy

- What happens to the feedstock during pyrolysis? A Guide to Controlled Thermal Decomposition

- What are the three types of pyrolysis process? Slow, Fast, and Conventional Explained

- What is the conversion of plastic to fuel by pyrolysis? A Complete Guide to Waste-to-Energy Technology

- What is the biochar in pyrolysis reaction? Unlocking Its Role in Soil Enhancement and Carbon Sequestration

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- What are the benefits of pyrolysis plastic? Transform Waste into Fuel & New Materials

- What are the factors affecting plastic pyrolysis? Optimize Yield and Quality from Waste Plastic