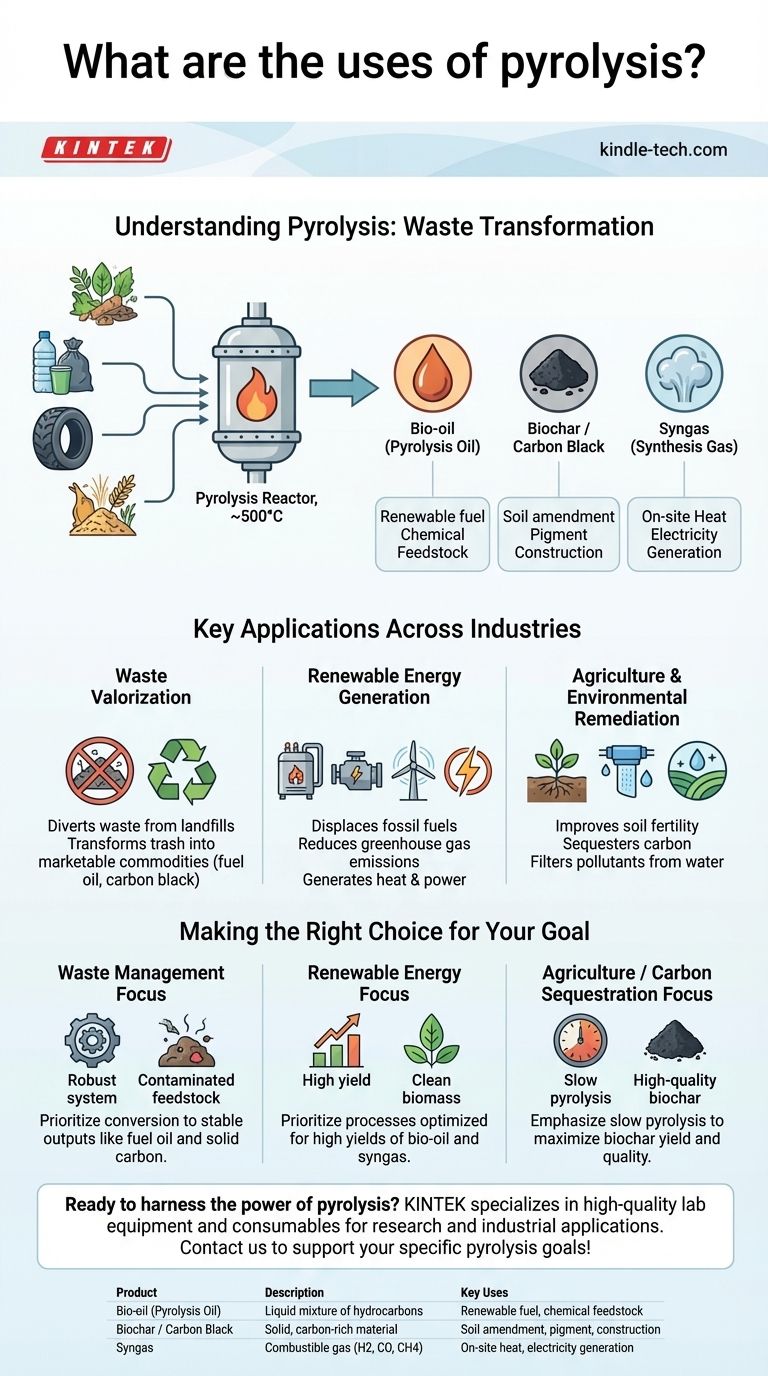

In essence, pyrolysis is a powerful tool for transformation. It is a thermochemical process that heats organic materials, such as biomass, plastic, or tires, in an oxygen-free environment. This controlled decomposition converts low-value waste streams into valuable products, including liquid fuels, solid carbon, and combustible gases, for use in energy generation, agriculture, and chemical manufacturing.

Pyrolysis should not be viewed simply as a disposal method. Its true value lies in its ability to valorize waste materials, transforming them from an environmental liability into a source of renewable energy and useful industrial products, supporting a more circular economy.

Understanding the Pyrolysis Process

How It Works: Thermal Decomposition Without Oxygen

Pyrolysis is fundamentally a case of thermolysis, or decomposition by heat. Organic material, such as wood chips or plastic waste, is fed into a reactor and heated to high temperatures, often around 500°C (932°F).

Crucially, this occurs in the absence of oxygen. This prevents combustion (burning) and instead causes the complex organic molecules to break down into simpler, smaller molecules. These molecules are then rapidly cooled and condensed, separating them into three distinct product streams.

The Three Core Products

The output of a pyrolysis system can be tuned by controlling the process conditions, but it generally yields a combination of three primary products.

Bio-oil (Pyrolysis Oil)

This liquid product is a complex mixture of oxygenated hydrocarbons. It can be refined and upgraded for use as a renewable transportation fuel or as a substitute for industrial fuel oil. It also serves as a feedstock for producing specialty chemicals.

Biochar (or Carbon Black)

This is the stable, solid, carbon-rich material left behind. When derived from biomass, it's called biochar and is highly valued as a soil amendment to improve fertility and water retention. When derived from waste like tires, the solid is called carbon black and can be used as a pigment, a reinforcing agent, or even mixed with clay to produce construction bricks.

Syngas (Synthesis Gas)

This non-condensable gas fraction is a mixture of hydrogen, carbon monoxide, carbon dioxide, and methane. Syngas is combustible and is typically captured and used on-site to provide the heat required for the pyrolysis reactor, making the process more energy-efficient. Excess gas can be used to generate electricity.

Key Applications Across Industries

The versatile outputs of pyrolysis enable its use across several key sectors, primarily focused on sustainability and resource efficiency.

Waste Valorization

Pyrolysis offers a powerful solution for managing difficult-to-recycle waste. It can effectively process mixed plastic waste, used tires, and agricultural residues, diverting them from landfills. The process transforms this "trash" into marketable commodities like fuel oil and carbon black.

Renewable Energy Generation

The bio-oil and syngas produced from biomass pyrolysis are considered renewable energy sources. Their use in boilers, engines, or turbines to generate heat and electricity displaces the need for fossil fuels, contributing to a reduction in net greenhouse gas emissions.

Agriculture and Environmental Remediation

Biochar is a key product for sustainable agriculture. When added to soil, it can sequester carbon for long periods, improve soil structure, and enhance nutrient availability for plants. Its porous structure also makes it an effective sorbent for filtering pollutants from water or a feedstock for producing high-grade activated carbon.

Understanding the Trade-offs

While powerful, pyrolysis is a sophisticated process with practical challenges that require careful management.

Product Yield and Quality

The exact ratio and chemical composition of the oil, char, and gas are highly dependent on the feedstock material and process parameters like temperature and heating rate. Optimizing for a high yield of liquid fuel may come at the expense of char production, and vice versa, requiring a clear goal for the operation.

Feedstock Contamination

The principle of "garbage in, garbage out" applies directly to pyrolysis. Contaminants in the waste stream (like metals, PVC plastic, or inorganic materials) can end up in the final products, potentially reducing their quality, damaging equipment, or creating hazardous byproducts that require further treatment.

Net Energy Balance

Pyrolysis is an endothermic process, meaning it requires a significant energy input to maintain its high operating temperatures. For the system to be environmentally and economically positive, the energy produced from the syngas and bio-oil must exceed the energy consumed by the process itself.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on your primary objective.

- If your primary focus is waste management: Select robust systems designed to handle diverse and potentially contaminated feedstocks, prioritizing conversion into stable outputs like fuel oil and solid carbon.

- If your primary focus is renewable energy: Prioritize processes optimized for high yields of bio-oil and syngas, ideally using a consistent and clean biomass feedstock to ensure fuel quality.

- If your primary focus is agriculture or carbon sequestration: Emphasize slow pyrolysis conditions that are specifically designed to maximize the yield and quality of biochar for use as a soil amendment.

Ultimately, pyrolysis provides a critical technological pathway to redefine waste as a valuable resource.

Summary Table:

| Product | Description | Key Uses |

|---|---|---|

| Bio-oil (Pyrolysis Oil) | Liquid mixture of hydrocarbons | Renewable fuel, chemical feedstock |

| Biochar / Carbon Black | Solid, carbon-rich material | Soil amendment, pigment, construction |

| Syngas | Combustible gas (H2, CO, CH4) | On-site heat, electricity generation |

Ready to harness the power of pyrolysis for your lab or facility? KINTEK specializes in high-quality lab equipment and consumables, including pyrolysis systems tailored for research and industrial applications. Whether you're focused on waste valorization, renewable energy, or biochar production, our solutions help you achieve efficient, reliable results. Contact us today to discuss how we can support your specific pyrolysis goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time