In short, thermal evaporation is a foundational technology for creating thin films, most commonly used to deposit metal layers for electronics, create reflective optical coatings, and apply decorative finishes. Its applications range from the conductive layers in OLED displays and solar cells to the reflective surfaces on automotive headlights and the metallic sheen on cosmetic packaging.

Thermal evaporation is a straightforward, cost-effective vacuum deposition process. Its value lies in its ability to quickly deposit high-purity films of materials with relatively low melting points, making it an indispensable tool for specific applications in electronics and optics where simplicity and material purity are paramount.

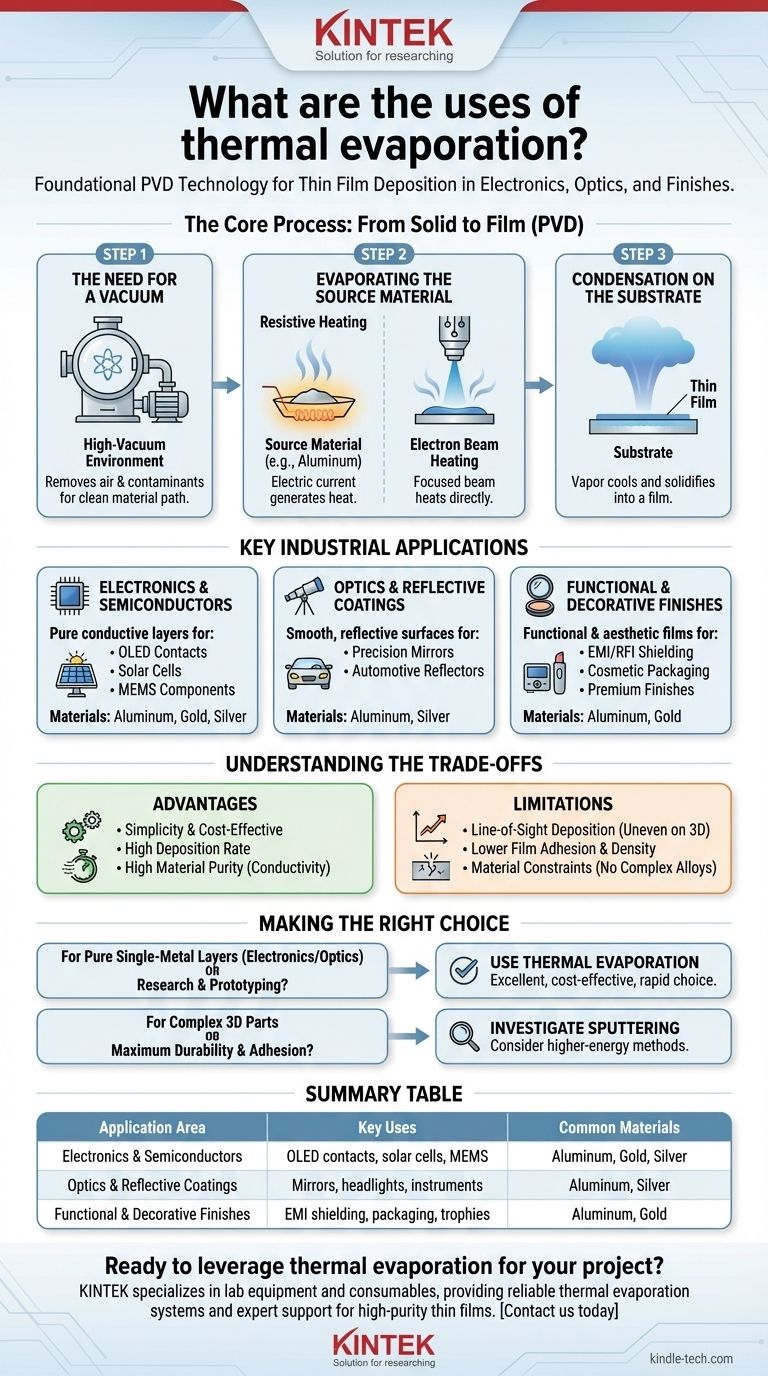

The Core Process: From Solid to Film

Thermal evaporation is a type of Physical Vapor Deposition (PVD). The principle is elegantly simple and mirrors the natural water cycle, but it occurs within a controlled, high-vacuum environment.

The Need for a Vacuum

The entire process takes place in a high-vacuum chamber. This vacuum is critical because it removes air and other gas molecules that could collide with the evaporated material, ensuring a clean and direct path from the source to the target.

Evaporating the Source Material

A source material, such as a pellet of aluminum or gold, is placed in a container called a crucible. This crucible is heated until the source material turns from a solid directly into a vapor. This heating is typically achieved through one of two methods:

- Resistive Heating: An electric current is passed through a refractory metal boat or filament holding the material, generating heat.

- Electron Beam Heating: A focused beam of high-energy electrons heats the source material directly.

Condensation on the Substrate

This vapor cloud expands throughout the chamber and lands on a cooler surface, known as the substrate. Upon contact, the vapor rapidly cools and condenses back into a solid, forming a thin, uniform film across the substrate's surface.

Key Industrial Applications

The simplicity and effectiveness of this process have made it a staple in numerous high-tech and consumer industries.

Electronics and Semiconductors

This is the most common application area. The ability to deposit pure, conductive metal layers is essential for modern electronics.

- Electrical Contacts: Creating contacts and interconnects on OLEDs, thin-film transistors, and other semiconductor devices using metals like aluminum or silver.

- Solar Cells: Depositing metal bonding layers that are critical for extracting electrical current.

- Microelectromechanical Systems (MEMS): Building up the microscopic components used in sensors and actuators.

Optics and Reflective Coatings

Thermal evaporation excels at creating highly reflective surfaces. The process produces a smooth film that is ideal for managing light.

- Reflectors: Manufacturing light reflectors for automotive headlights, medical lighting, and aerospace equipment.

- Mirrors: Creating the reflective layers on precision mirrors for telescopes and other optical instruments.

Functional and Decorative Finishes

The process is also widely used to apply films that serve a functional or purely aesthetic purpose.

- EMI/RFI Shielding: Depositing a thin layer of metal onto plastic housings for electronic devices to block electromagnetic or radio-frequency interference.

- Decorative Coatings: Applying a metallic finish to items like cosmetic closures, trophies, and sporting goods to give them a premium look at a low cost.

Understanding the Trade-offs

No single technology is perfect for every job. Choosing thermal evaporation requires understanding its distinct advantages and limitations.

The Advantage: Simplicity and Cost

Thermal evaporation systems are mechanically simpler and generally less expensive than other PVD methods like sputtering. This makes the technology highly accessible for research, prototyping, and cost-sensitive production.

The Advantage: High Deposition Rate and Purity

For many materials, especially metals with low melting points like aluminum, the process is very fast. Because the material is simply evaporated, the resulting film maintains a very high level of purity, which is critical for electrical conductivity.

The Limitation: Line-of-Sight Deposition

The evaporated material travels in a straight line from the source to the substrate. This line-of-sight nature means it is difficult to evenly coat complex, three-dimensional shapes without sophisticated rotating fixtures.

The Limitation: Film Adhesion and Density

Because the evaporated atoms arrive at the substrate with relatively low energy, the resulting films can be less dense and have weaker adhesion compared to films from more energetic processes like sputtering. While the adhesion is good enough for many applications, it may not be suitable for high-wear or high-stress environments.

The Limitation: Material Constraints

The process is best suited for materials that can be heated to a vapor state without decomposing or reacting chemically. Complex alloys or compounds can be difficult to deposit with consistent stoichiometry.

Making the Right Choice for Your Application

To determine if thermal evaporation is the correct approach, consider your primary goal.

- If your primary focus is depositing pure, single-metal layers for electronics or optics: Thermal evaporation is an excellent, cost-effective, and rapid choice.

- If your primary focus is on research, development, or rapid prototyping of thin films: The simplicity and low cost of this technology make it an ideal starting point.

- If your primary focus is coating complex 3D parts or achieving maximum durability and adhesion: You should investigate higher-energy deposition methods like magnetron sputtering.

Ultimately, understanding the fundamental principles of thermal evaporation allows you to leverage its strengths for the precise applications where it truly excels.

Summary Table:

| Application Area | Key Uses | Common Materials |

|---|---|---|

| Electronics & Semiconductors | OLED contacts, solar cell layers, MEMS components | Aluminum, Gold, Silver |

| Optics & Reflective Coatings | Mirrors, automotive headlights, precision instruments | Aluminum, Silver |

| Functional & Decorative Finishes | EMI shielding, cosmetic packaging, trophies | Aluminum, Gold |

Ready to leverage thermal evaporation for your project? KINTEK specializes in lab equipment and consumables, providing reliable thermal evaporation systems and expert support to help you achieve high-purity thin films for electronics, optics, and more. Contact us today to discuss your specific laboratory needs and discover the right solution for your application!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the deposition rate of thermal evaporation? Master the Key Variables for Your Thin Films

- What is the process of evaporation coating? A Guide to Thin Film Deposition

- What thin films are deposited by electron beam evaporation? Unlock High-Performance Coatings

- What is the physical deposition technique? A Guide to PVD Coating Methods & Applications

- What is the difference between sputtering and e beam evaporation? Choose the Right PVD Method for Your Thin Film

- What materials are used in e-beam evaporation? From Pure Metals to High-Temp Ceramics

- Is electron beam assisted evaporation used for metals? The Key to High-Purity, High-Melting-Point Metal Films

- What are the steps of physical vapour deposition? A Guide to the 3-Step PVD Process