At their core, modern Ultra-Low Temperature (ULT) freezers are integrating automation and AI to shift from reactive failure alerts to proactive sample protection. Key features include AI-powered predictive maintenance that anticipates malfunctions, automated temperature management optimized for specific samples, and real-time remote monitoring systems that provide constant oversight and control.

The integration of smart technology is fundamentally changing the role of a ULT freezer. It is no longer a passive cold box with an alarm, but an active, intelligent system designed to predict failures, optimize performance, and guarantee the integrity of invaluable biological samples.

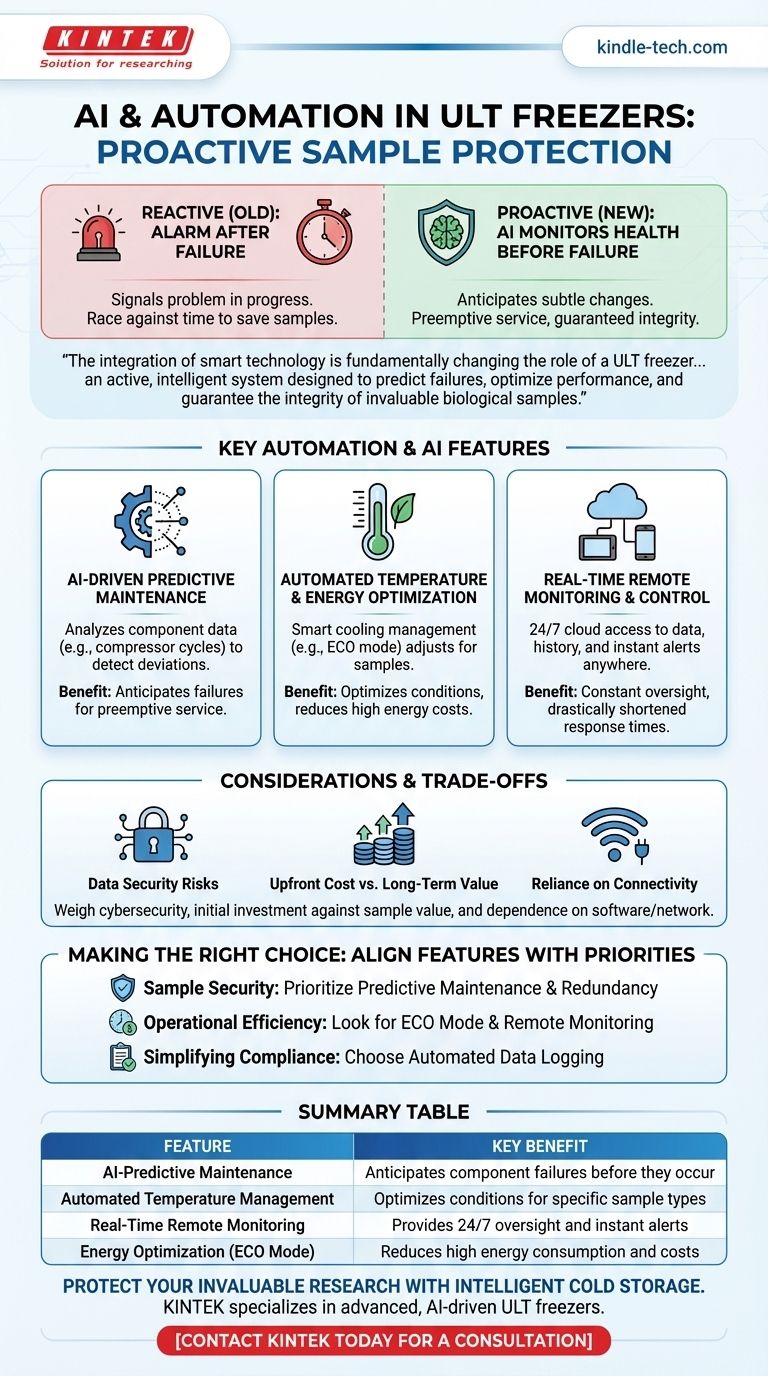

The Shift from Reactive Alarms to Proactive Intelligence

For decades, the primary "smart" feature of a ULT freezer was an alarm that triggered during a temperature deviation or power failure. This model is inherently flawed because it only alerts you after a problem has begun, initiating a race against time to save samples.

The Problem with Traditional Alarms

Traditional alarm systems are purely reactive. They signal a failure in progress, often leaving lab staff with a narrow window to respond before samples are compromised.

This approach fails to address the root cause and offers no warning of impending mechanical stress or component degradation, which are the typical precursors to catastrophic failure.

The Goal of Modern Automation: Prevention

The new generation of ULT freezers uses automation and AI to monitor the health of the system itself, not just the temperature inside.

The objective is to identify subtle changes in performance—like compressor cycle times or energy consumption patterns—that indicate a potential failure is on the horizon. This allows for scheduled maintenance long before a critical event occurs.

Key Automation and AI Features Explained

These intelligent features work together to create a robust ecosystem for sample security and operational efficiency. They move beyond simple temperature logging to provide deep, actionable insights into the freezer's performance and health.

AI-Driven Predictive Maintenance

This is the most significant advancement. The freezer's control system continuously analyzes data from its own components, such as the compressors and cooling systems.

Using AI algorithms, it can detect subtle deviations from normal operating parameters. The system can then issue an alert, such as "Compressor A is running 15% longer than baseline," predicting a future failure and enabling preemptive service.

Automated Temperature and Energy Optimization

Modern freezers use automation to manage their cooling cycles with greater intelligence. An ECO mode, for example, can adjust performance to reduce energy consumption during periods of low activity, such as overnight or on weekends.

Some systems can even optimize temperature management based on the type of samples stored, ensuring ideal conditions while minimizing the energy draw required to maintain them. This helps manage the high energy costs associated with powerful cascade refrigeration systems.

Real-Time Remote Monitoring and Control

Nearly all smart ULT freezers now offer cloud-based remote monitoring. This allows lab managers and technicians to view real-time temperature data, access performance history, and receive alerts on any device, anywhere.

This constant connectivity ensures that a temperature deviation or system alert is seen immediately by all designated personnel, dramatically shortening response times and preventing information from being siloed.

Understanding the Trade-offs

While these features offer transformative benefits, they also introduce new considerations that must be weighed before purchase. True technical guidance requires acknowledging the potential downsides.

Integration and Data Security

Connecting a critical piece of lab equipment to a network introduces cybersecurity risks. You must ensure your lab's network is secure and that the freezer manufacturer has robust data protection protocols.

Upfront Cost vs. Long-Term Value

Intelligent ULT freezers carry a higher initial purchase price than their non-automated counterparts. This cost must be evaluated against the immense financial and scientific value of the samples they protect.

The potential loss from a single freezer failure often far exceeds the price difference. Furthermore, energy optimization features can provide a tangible return on investment over the freezer's lifespan.

Reliance on Software and Connectivity

These advanced features are dependent on software and, in the case of remote monitoring, a stable internet connection. It is crucial to consider the manufacturer's track record for software support, updates, and the system's ability to function locally if connectivity is lost.

Making the Right Choice for Your Lab

Selecting the right ULT freezer requires aligning its features with your laboratory's most critical priorities.

- If your primary focus is irreplaceable sample security: Prioritize a unit with proven AI-driven predictive maintenance and a dual, independent cooling system for ultimate redundancy.

- If your primary focus is operational efficiency and cost: Look for advanced remote monitoring to reduce manual checks and an automated ECO mode to manage high energy consumption.

- If your primary focus is simplifying compliance: Choose a freezer with comprehensive, automated data logging and reporting features that can be easily exported for audits.

By understanding the shift from passive storage to active system management, you can make an informed decision that secures your research for years to come.

Summary Table:

| Feature | Key Benefit |

|---|---|

| AI-Predictive Maintenance | Anticipates component failures before they occur |

| Automated Temperature Management | Optimizes conditions for specific sample types |

| Real-Time Remote Monitoring | Provides 24/7 oversight and instant alerts |

| Energy Optimization (ECO Mode) | Reduces high energy consumption and costs |

Protect your invaluable research with intelligent cold storage.

Modern Ultra-Low Temperature (ULT) freezers are no longer simple appliances; they are active, AI-driven systems designed to prevent sample loss and optimize lab operations. KINTEK specializes in providing advanced lab equipment, including intelligent ULT freezers, to meet the critical demands of research and clinical laboratories.

Let our experts help you select the right freezer with the automation features your lab needs for superior sample security, operational efficiency, and compliance.

Contact KINTEK today for a personalized consultation and secure your research's future.

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

People Also Ask

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation