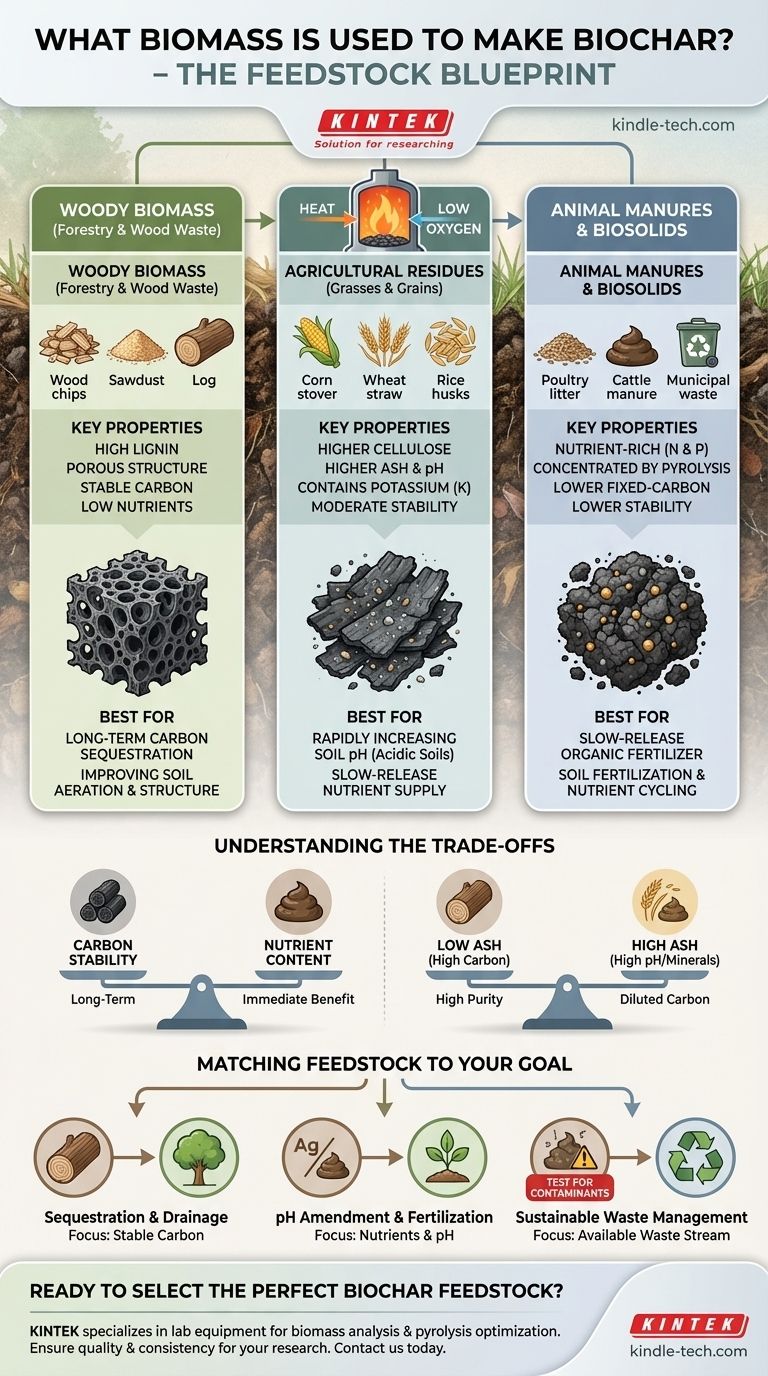

In short, almost any form of organic material, or biomass, can be used to make biochar. This includes a vast range of feedstocks, from forestry and agricultural waste like wood chips and corn stover to nutrient-rich sources like animal manure and even municipal biosolids. The specific biomass used is the single most important factor determining the final biochar's characteristics.

The central takeaway is that the type of biomass feedstock is not just a starting ingredient; it is the blueprint for the biochar's final properties. The choice of feedstock dictates the biochar's structure, pH, nutrient content, and suitability for specific applications like carbon sequestration or soil fertilization.

Why Feedstock is the Critical First Step

The process of creating biochar, known as pyrolysis, involves heating biomass in a low-oxygen environment. While process conditions like temperature and time are important variables, they can only modify what the original feedstock provides.

The fundamental chemical and physical structure of the source material dictates the potential of the end product. Think of it as the difference between baking a cake with wheat flour versus almond flour—the core ingredient defines the outcome.

Common Categories of Biochar Feedstock

Different biomass sources produce biochars with distinct and predictable properties. Understanding these categories is key to selecting the right product for your goal.

Woody Biomass (Forestry and Wood Waste)

Sources like wood chips, sawdust, forestry residues, and wood pellets are common feedstocks.

These materials are high in lignin, a complex organic polymer that provides rigidity to wood. This results in a biochar that is highly porous, structurally stable, and has a high fixed-carbon content.

This structure makes woody biochar excellent for improving soil aeration, water retention, and providing a long-term habitat for beneficial microbes. It is the superior choice for long-term carbon sequestration.

Agricultural Residues (Grasses and Grains)

This category includes materials like corn stover, wheat straw, rice husks, and sugar cane bagasse.

These feedstocks are typically higher in cellulose and have a greater ash content. The resulting biochar often has a higher pH and contains more available nutrients, particularly potassium (K).

Biochar from these sources is well-suited for rapidly increasing soil pH in acidic soils and providing a modest, slow-release source of plant-available nutrients.

Animal Manures and Biosolids

Feedstocks such as poultry litter, cattle manure, and municipal biosolids are rich in nutrients from the start.

Pyrolysis concentrates these nutrients, primarily nitrogen (N) and phosphorus (P). The final biochar acts more like a slow-release organic fertilizer than a simple soil conditioner.

However, these biochars often have a lower fixed-carbon content and less physical stability compared to woody biochars, making them less effective for long-term carbon storage.

Understanding the Trade-offs

Choosing a biochar feedstock involves balancing competing priorities. What makes a biochar good for one purpose may make it less suitable for another.

Carbon Stability vs. Nutrient Content

There is a fundamental trade-off between long-term carbon storage and immediate nutrient benefit.

High-lignin woody feedstocks produce highly stable biochar that can lock carbon away for centuries. However, it is generally low in plant-available nutrients.

Manures and agricultural residues produce biochar that provides valuable nutrients but has a lower proportion of stable carbon, meaning its carbon sequestration value is reduced.

The Impact of Ash Content

Ash is the inorganic, non-combustible portion of biomass, containing minerals like silica, potassium, and calcium.

Feedstocks like rice husks (high in silica) and manures produce a high-ash biochar. This can be beneficial for raising soil pH and supplying minerals but dilutes the overall carbon percentage of the product.

Contaminants and Feedstock Purity

The source of the biomass is paramount. Biochar made from contaminated materials will produce contaminated biochar, as the pyrolysis process can concentrate heavy metals and other pollutants.

Always ensure the feedstock is clean, especially if the biochar is intended for agricultural use. Waste from construction or industrial processes must be carefully scrutinized before use.

Matching the Feedstock to Your Goal

Your intended application should guide your choice of biochar.

- If your primary focus is long-term carbon sequestration and improving soil drainage: Choose a biochar made from high-lignin woody biomass like wood chips or forestry waste.

- If your primary focus is raising the pH of acidic soil and providing nutrients: Look for biochar made from agricultural residues or nutrient-dense sources like certified manure.

- If your primary focus is sustainable waste management: Your choice is defined by the available waste stream, but you must prioritize testing for contaminants before land application.

Ultimately, understanding the origin of your biochar is the key to unlocking its full potential for your specific application.

Summary Table:

| Feedstock Category | Common Sources | Key Biochar Properties | Best For |

|---|---|---|---|

| Woody Biomass | Wood chips, sawdust, forestry waste | High porosity, stable carbon, good for soil structure | Long-term carbon sequestration, soil aeration |

| Agricultural Residues | Corn stover, rice husks, straw | Higher pH, nutrient-rich (e.g., potassium) | Amending acidic soils, slow-release fertilization |

| Animal Manures & Biosolids | Poultry litter, cattle manure | Concentrated nitrogen & phosphorus | Soil fertilization, nutrient cycling |

Ready to select the perfect biochar for your project? The right feedstock is critical for success. At KINTEK, we specialize in lab equipment for biomass analysis and pyrolysis, helping researchers and producers characterize feedstocks and optimize biochar production. Whether you're working with agricultural waste, forestry residues, or other organic materials, our solutions ensure quality and consistency. Contact us today (#ContactForm) to discuss how we can support your biochar development and application goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

- High Performance Laboratory Freeze Dryer

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process