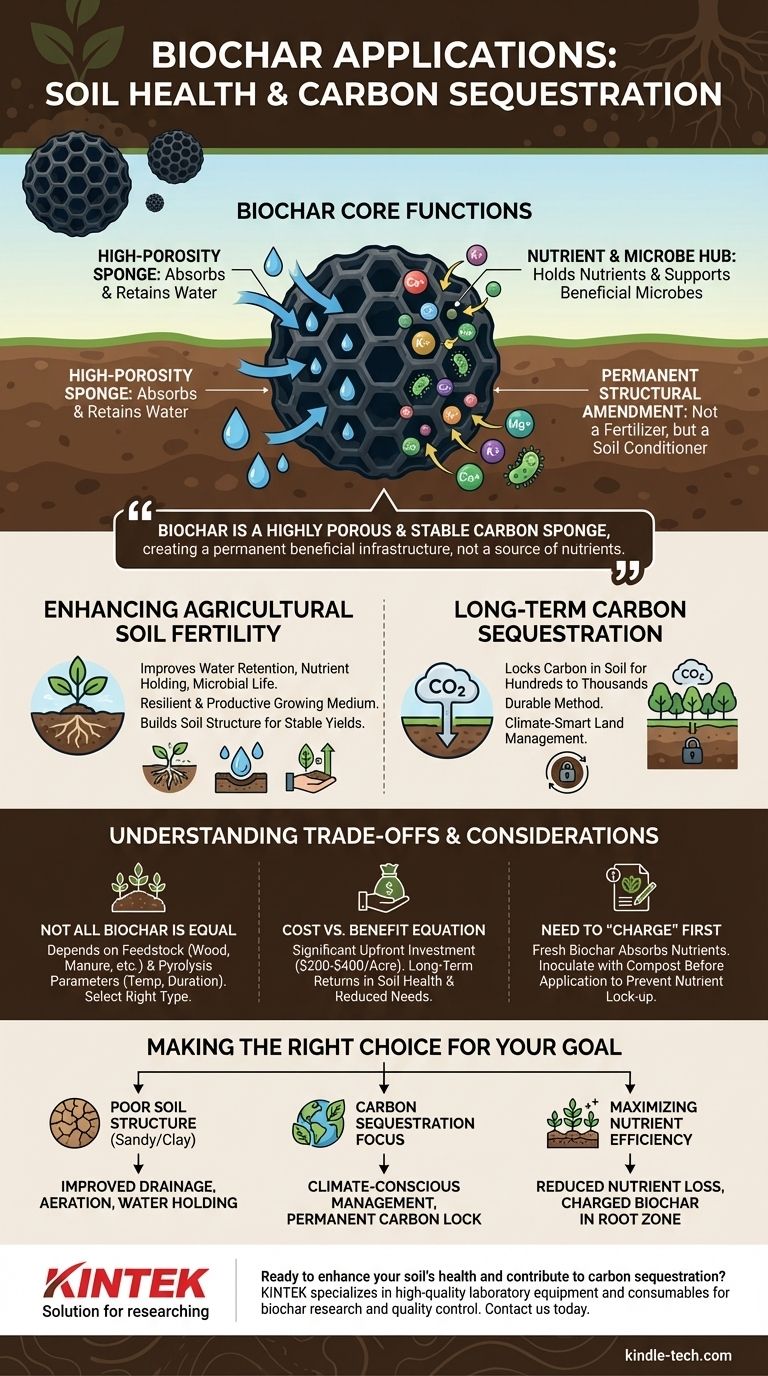

At its core, biochar is used for two primary purposes: enhancing soil health and sequestering carbon. It acts as a permanent structural amendment to soil, fundamentally changing its physical and chemical properties for the long term rather than acting as a short-term fertilizer.

The most critical thing to understand is that biochar is not a source of nutrients itself. Instead, it is a highly porous and stable carbon sponge that creates a permanent, beneficial infrastructure within your soil, improving its ability to retain water, hold onto nutrients, and support microbial life.

How Biochar Fundamentally Changes Soil

To understand biochar's applications, you must first understand its mechanism. It is created through a process called pyrolysis—heating organic biomass in a low-oxygen environment. This process creates a remarkably stable, carbon-rich material.

A High-Porosity "Sponge" for Water

The structure of biochar is incredibly porous, filled with microscopic cavities. This structure allows it to act like a sponge, absorbing and holding water within the soil.

This improves a soil's water-holding capacity, making moisture more available to plant roots during dry periods and reducing overall irrigation needs.

A Hub for Nutrients and Microbes

Biochar's surface chemistry gives it a negative charge, which allows it to attract and hold positively charged ions.

Many essential plant nutrients, such as calcium, potassium, and magnesium, are positive ions. Biochar holds these nutrients in the root zone, preventing them from being washed away by rain or irrigation. Its porous structure also provides an ideal habitat for beneficial soil microorganisms.

A Soil Conditioner, Not a Fertilizer

This is a common point of confusion. Applying biochar will not add significant nitrogen, phosphorus, or potassium to your soil.

Its primary function is to condition the soil, making the existing environment and any future amendments you add far more effective. It improves the efficiency of your fertilizers, but it does not replace them.

Key Applications for Biochar

The unique properties of biochar lead to its two main, interconnected applications. It is an investment in the foundational health of your soil and the environment.

Enhancing Agricultural Soil Fertility

This is biochar's most well-known use. By improving water retention and nutrient holding capacity, it creates a more resilient and productive growing medium.

Organic farmers, in particular, value its ability to build soil structure over many years. This can lead to more stable yields, especially in poor or degraded soils.

Long-Term Carbon Sequestration

The carbon in biochar is extremely stable and resistant to decomposition. When added to soil, it can remain there for hundreds or even thousands of years.

This process effectively takes carbon that was captured from the atmosphere by plants and locks it away in the ground. It is one of the most durable methods of carbon sequestration currently available.

Understanding the Trade-offs and Considerations

While powerful, biochar is not a magic bullet. Its effectiveness depends entirely on its quality and how it is used.

Not All Biochar is Created Equal

The final properties of biochar depend heavily on the biomass feedstock (e.g., wood, manure, crop residue) and the pyrolysis parameters (e.g., temperature, duration).

Biochar made from wood at high temperatures will have different characteristics (like a higher pH) than biochar made from manure at low temperatures. Selecting the right type for your specific soil is crucial for success.

The Cost vs. Benefit Equation

As noted, amending soil with biochar can cost between $200 and $400 per acre. This is a significant upfront investment.

The return on this investment is realized over the long term through improved soil health, reduced fertilizer and water needs, and potentially higher crop resilience. It is not a quick fix for a single growing season.

The Need to "Charge" Biochar First

Fresh, raw biochar is so effective at absorbing nutrients that it can temporarily pull them from the surrounding soil, making them unavailable to plants.

For this reason, it is considered best practice to "charge" or "inoculate" biochar before application. This is done by mixing it with a nutrient-rich material like compost, letting it absorb the nutrients and microbes for several weeks before adding it to your soil.

Making the Right Choice for Your Goal

Applying biochar should be a strategic decision based on a clear objective.

- If your primary focus is improving poor soil structure: Biochar is an excellent long-term investment for sandy soils that don't hold water or heavy clay soils that need better drainage and aeration.

- If your primary focus is carbon sequestration: Biochar is one of the most effective and permanent ways to lock carbon in the soil, making it a powerful tool for climate-conscious land management.

- If your primary focus is maximizing nutrient efficiency: In high-value farming or gardening, charged biochar can help keep expensive nutrients in the root zone and reduce losses from runoff.

Ultimately, think of biochar as a permanent upgrade to your soil's fundamental operating system.

Summary Table:

| Application | Key Benefit | Primary Use Case |

|---|---|---|

| Soil Fertility | Improves water retention, nutrient holding capacity, and microbial life. | Agriculture, gardening, degraded soil restoration. |

| Carbon Sequestration | Locks carbon in soil for hundreds to thousands of years. | Climate-smart land management, sustainability projects. |

| Soil Conditioning | Enhances soil structure and fertilizer efficiency. | High-value farming, organic agriculture. |

Ready to enhance your soil's health and contribute to carbon sequestration? KINTEK specializes in high-quality laboratory equipment and consumables essential for biochar research and quality control. Whether you're in agriculture, environmental science, or sustainability, our solutions help you analyze biochar properties and optimize its application. Contact us today to learn how we can support your lab's needs with reliable, precision equipment.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the different types of pyrolysis machines? Choose the Right System for Your Output