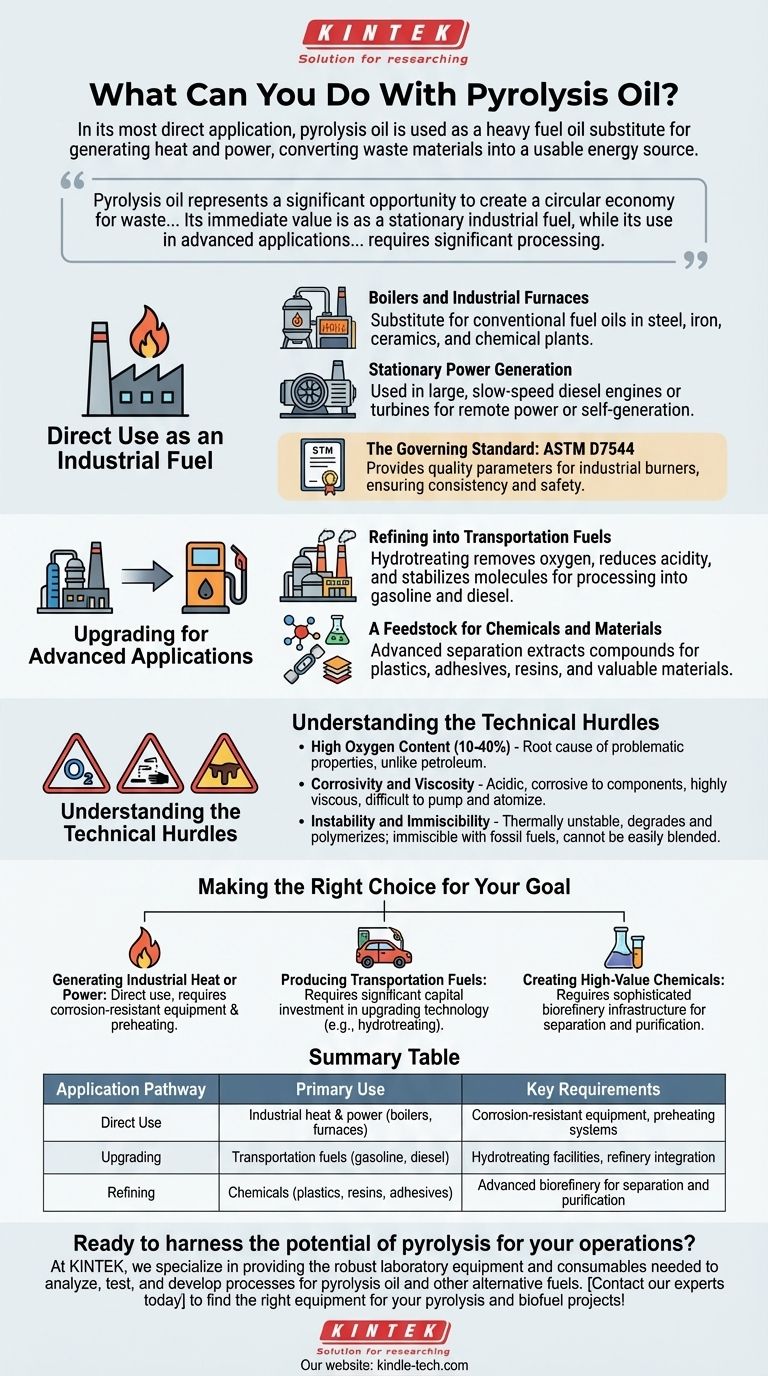

In its most direct application, pyrolysis oil is used as a heavy fuel oil substitute for generating heat and power in industrial settings. It can be burned in boilers, furnaces, and certain types of generators, providing a way to convert waste materials like plastics or biomass into a usable energy source.

Pyrolysis oil represents a significant opportunity to create a circular economy for waste, but its raw form is fundamentally different from petroleum. Its immediate value is as a stationary industrial fuel, while its use in advanced applications like transportation requires significant processing to overcome its inherent chemical challenges.

Direct Use as an Industrial Fuel

The most straightforward application for pyrolysis oil is to leverage its high heating value by burning it in stationary equipment. This path requires the least amount of post-processing but often necessitates modifications to the combustion systems.

Boilers and Industrial Furnaces

Raw pyrolysis oil can serve as a substitute for conventional fuel oils in large industrial heating systems. Industries like steel and iron manufacturing, ceramics, and chemical plants can use it as a primary energy source for their processes.

Stationary Power Generation

The oil can be used in large, slow-speed diesel engines or turbines designed for power generation. This is common in remote power installations or for facilities looking to generate their own electricity from a waste feedstock.

The Governing Standard: ASTM D7544

For use as a burner fuel, pyrolysis oil is often graded against the ASTM D7544 standard. This specification provides quality parameters for its use in industrial burners, ensuring a degree of consistency and safety for stationary applications.

Upgrading for Advanced Applications

To unlock the full potential of pyrolysis oil, particularly for transportation or high-value products, it must undergo further treatment. This "upgrading" process aims to make its properties more closely resemble those of refined petroleum.

Refining into Transportation Fuels

By upgrading the oil through processes like hydrotreating, it's possible to remove oxygen, reduce acidity, and stabilize the molecules. The resulting synthetic crude oil can then be processed in a conventional refinery to produce hydrocarbon fuels like gasoline and diesel.

A Feedstock for Chemicals and Materials

Pyrolysis oil is not just a fuel; it's a complex mixture of chemical compounds. With advanced separation and refining, these compounds can be extracted to produce plastics, adhesives, resins, and other valuable materials.

Understanding the Technical Hurdles

The industrial use of raw pyrolysis oil is not a simple drop-in replacement for diesel or furnace oil. Its unique chemical nature presents several significant challenges that limit its application.

The Problem of High Oxygen Content

Unlike petroleum, which is almost purely hydrocarbons, pyrolysis oil contains a significant amount of oxygen (often 10-40%). This oxygen content is the root cause of its most problematic properties.

Corrosivity and Viscosity

The high oxygen content makes the oil acidic and corrosive to standard pipes, pumps, and engine components. It is also highly viscous (thick), making it difficult to pump and atomize in an injector without preheating.

Instability and Immiscibility

Pyrolysis oil is thermally unstable, meaning it can degrade and polymerize (thicken into solids) when heated or simply over time in storage. It is also immiscible with fossil fuels, so it cannot be easily blended.

Making the Right Choice for Your Goal

The best use for pyrolysis oil depends entirely on your available infrastructure, investment capacity, and ultimate objective.

- If your primary focus is generating industrial heat or power: Use the oil directly as a heavy fuel substitute in boilers or stationary generators, but be prepared to invest in corrosion-resistant equipment and preheating systems.

- If your primary focus is producing transportation fuels: Recognize that a significant capital investment in upgrading technology, such as hydrotreating facilities, is non-negotiable to create a stable, refinable product.

- If your primary focus is creating high-value chemicals: This path requires sophisticated and specialized biorefinery infrastructure to isolate and purify the desired chemical compounds from the complex oil mixture.

Understanding these distinct application pathways and their associated technical requirements is the key to unlocking the true value of pyrolysis oil.

Summary Table:

| Application Pathway | Primary Use | Key Requirements |

|---|---|---|

| Direct Use | Industrial heat & power (boilers, furnaces) | Corrosion-resistant equipment, preheating systems |

| Upgrading | Transportation fuels (gasoline, diesel) | Hydrotreating facilities, refinery integration |

| Refining | Chemicals (plastics, resins, adhesives) | Advanced biorefinery for separation and purification |

Ready to harness the potential of pyrolysis for your operations?

At KINTEK, we specialize in providing the robust laboratory equipment and consumables needed to analyze, test, and develop processes for pyrolysis oil and other alternative fuels. Whether you're researching upgrading techniques, testing material compatibility, or scaling your process, our solutions help you overcome technical hurdles efficiently.

Contact our experts today to find the right equipment for your pyrolysis and biofuel projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Graphite Vacuum Continuous Graphitization Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas