At its core, Physical Vapor Deposition (PVD) is not a painting process, so it doesn't have "colors" in the traditional sense. Instead, PVD creates a wide spectrum of durable, metallic finishes by depositing a very thin film of material onto a surface. The color you see is the inherent optical property of that specific ceramic or metallic compound, resulting in finishes like gold, rose gold, black, bronze, and shades of blue, purple, and gray.

The essential takeaway is that PVD color is not a pigment or dye. It is the direct result of a specific material, often a metal nitride or carbide, being atomically bonded to a surface in a vacuum, creating a finish that is both vibrant and exceptionally hard.

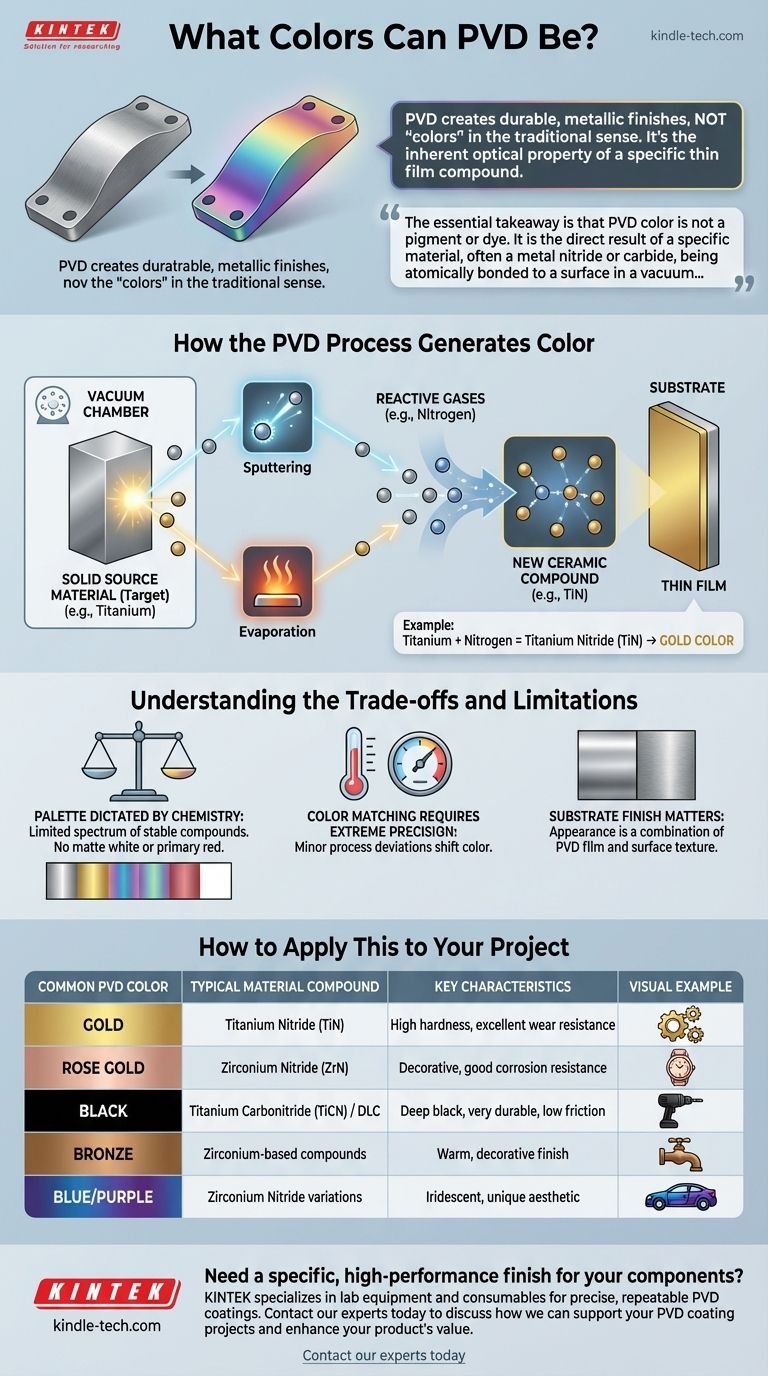

How the PVD Process Generates Color

To understand the color options, you must first understand the process. The color is an outcome of a highly controlled physics-based procedure, not a simple application of a coating.

It Starts with a Solid Source Material

The process begins by selecting a solid, pure material, known as a target. This target is the source of the coating and the primary determinant of the final color and properties. For example, titanium or zirconium are common targets.

The Material Becomes a Vapor

Inside a high-vacuum chamber, this target material is transformed into atomic particles. The references point to two primary methods for this:

- Sputtering: An ion beam bombards the target, dislodging atoms from its surface.

- Evaporation: The target is heated until it literally boils and evaporates.

Reactive Gases Create the Compound

This is the critical step for color creation. While the metal vapor travels toward the object being coated (the substrate), a specific reactive gas, such as nitrogen or a hydrocarbon, is precisely introduced into the chamber. The metal atoms react with the gas to form a new ceramic compound on the substrate's surface.

For instance, a titanium target reacting with nitrogen gas will form Titanium Nitride (TiN), which has a distinct gold color. Changing the gas or its ratio changes the compound and, therefore, the color.

A Thin Film is Formed

These newly formed compound particles deposit onto the substrate, building a thin, dense, and strongly bonded film. The final perceived color is a function of this film's composition and thickness, which determines how it reflects and refracts light.

Understanding the Trade-offs and Limitations

While powerful, the PVD process has inherent constraints that influence color choices. It is a technical process governed by physics, not an artistic one with infinite options.

The Palette is Dictated by Chemistry

You cannot create any color imaginable with PVD. The available color spectrum is limited to the stable, hard ceramic compounds that can be formed from suitable target materials and reactive gases. This is why PVD excels at producing brilliant metallic and iridescent finishes but cannot produce a matte white or a vibrant primary red.

Color Matching Requires Extreme Precision

Achieving the exact same shade of "gold" or "graphite" from one batch to the next requires immaculate control over every variable in the process—vacuum pressure, temperature, gas mixture, and deposition time. Minor deviations can cause visible shifts in color.

The Substrate Finish Matters

The final appearance is a combination of the PVD film and the surface underneath it. A PVD coating on a highly polished surface will look bright and reflective, while the same coating on a brushed or matte surface will have a muted, satin appearance. The coating is so thin that it conforms perfectly to the existing texture.

How to Apply This to Your Project

Your choice should be guided by the desired physical properties as much as the aesthetic.

- If your primary focus is extreme durability and wear resistance: Focus on standard industrial coatings like Titanium Nitride (gold) or Titanium Carbonitride (gray/black), as these are well-understood and optimized for performance.

- If your primary focus is a unique decorative aesthetic: Explore options using zirconium targets, which can produce a wider range of colors like bronze, rose gold, and even blues and purples, though these may have different wear characteristics.

- If your primary focus is a true black finish: Coatings like Diamond-Like Carbon (DLC) or those using chromium or titanium targets with specific gases are the industry standard for creating deep, lasting black surfaces.

Ultimately, the color of a PVD finish is an inseparable part of its high-performance physical properties.

Summary Table:

| Common PVD Color | Typical Material Compound | Key Characteristics |

|---|---|---|

| Gold | Titanium Nitride (TiN) | High hardness, excellent wear resistance |

| Rose Gold | Zirconium Nitride (ZrN) | Decorative, good corrosion resistance |

| Black | Titanium Carbonitride (TiCN) / DLC | Deep black, very durable, low friction |

| Bronze | Zirconium-based compounds | Warm, decorative finish |

| Blue/Purple | Zirconium Nitride with variations | Iridescent, unique aesthetic |

Need a specific, high-performance finish for your components?

The right PVD color is more than just an aesthetic choice—it's a critical decision for durability and performance. KINTEK specializes in providing the lab equipment and consumables needed to achieve precise, repeatable PVD coatings for industries ranging from aerospace to medical devices.

Our expertise can help you select the ideal coating material and process parameters to meet your exact requirements for hardness, corrosion resistance, and appearance.

Contact our experts today to discuss how we can support your PVD coating projects and enhance your product's value.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition