The choice of a lab equipment manufacturer is a critical decision that extends far beyond a simple price comparison. Companies select partners based on a rigorous evaluation of product quality, the manufacturer's reliability, and the depth of their post-sale support, recognizing that the right equipment is a long-term investment in data integrity and operational efficiency.

Choosing a lab equipment manufacturer is not a transaction; it's the beginning of a long-term technical partnership. The most successful decisions prioritize total cost of ownership and reliability over the initial sticker price, ensuring the integrity of future work.

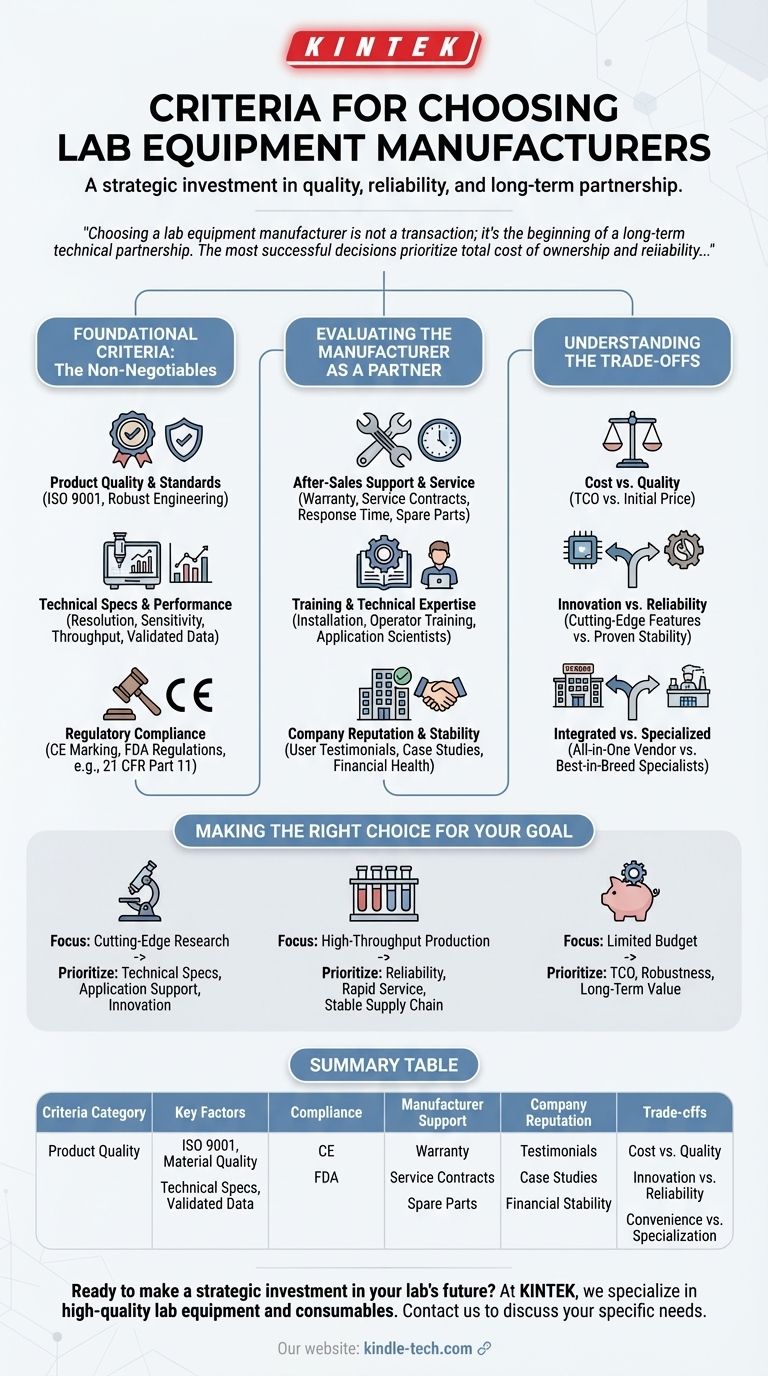

Foundational Criteria: The Non-Negotiables

Before considering price or features, the equipment and its manufacturer must meet a baseline of quality and compliance. These are the absolute requirements that protect your operations and results.

Product Quality and Manufacturing Standards

The physical quality of the instrument is paramount. Look for evidence of robust engineering, high-quality materials, and adherence to internationally recognized manufacturing standards like ISO 9001. This certification indicates the manufacturer has a proven quality management system.

Technical Specifications and Performance

The equipment must be capable of performing its intended task with verifiable precision and accuracy. Scrutinize the technical data sheets for key metrics like resolution, sensitivity, throughput, and range. A reputable manufacturer will provide clear performance data, often validated by third parties or published research.

Regulatory Compliance and Certification

For many industries, especially pharmaceuticals, biotech, and clinical diagnostics, regulatory compliance is non-negotiable. Ensure the equipment carries necessary certifications such as CE marking for Europe or is manufactured in compliance with FDA regulations (e.g., 21 CFR Part 11 for software) if applicable to your work.

Evaluating the Manufacturer as a Partner

The product is only one part of the equation. The company behind it determines your experience over the lifespan of the equipment, especially when you need support.

After-Sales Support and Service

Downtime is a critical risk in any lab. A key evaluation point is the manufacturer's service infrastructure. Ask about the terms of the warranty, the cost and structure of service contracts, the guaranteed response time for technicians, and the availability of spare parts.

Training and Technical Expertise

Even the best equipment is useless if your team cannot operate it effectively. A strong partner provides comprehensive installation and operator training. Furthermore, look for accessible application scientists who can help you optimize protocols and troubleshoot scientific challenges.

Company Reputation and Stability

You are investing in a relationship that should last for years. Investigate the manufacturer's reputation through peer reviews, user testimonials, and case studies. A long history and financial stability suggest the company will be around to support your instrument for its entire lifecycle.

Understanding the Trade-offs

Every purchasing decision involves balancing competing priorities. Being aware of these common trade-offs allows you to make a conscious choice that aligns with your lab's specific goals.

Cost vs. Quality

The cheapest instrument is rarely the least expensive to own. A low initial purchase price can conceal future costs from frequent breakdowns, poor data quality, and expensive proprietary consumables. Calculating the Total Cost of Ownership (TCO) provides a more accurate financial picture.

Cutting-Edge Features vs. Proven Reliability

New technology offers the potential for novel capabilities but may come with undiscovered bugs and a lack of established best practices. An older, more established model may offer fewer features but provides a track record of stability and reliability. This is a direct trade-off between innovation and risk.

All-in-One Vendor vs. Best-in-Breed Specialists

Sourcing all equipment from a single large vendor can simplify purchasing and service. However, a specialized manufacturer often offers deeper expertise and superior performance for a specific type of instrument. The choice is between integrated convenience and specialized excellence.

Making the Right Choice for Your Goal

Your final decision should be guided by your lab's primary mission. Use these scenarios to weigh the criteria based on what matters most to you.

- If your primary focus is cutting-edge research: Prioritize manufacturers with leading-edge technical specifications, strong application support for novel methods, and a record of innovation.

- If your primary focus is high-throughput production or diagnostics: Emphasize documented reliability, rapid-response service contracts, and a stable supply chain for all necessary reagents and consumables.

- If your primary focus is operating on a limited budget: Look beyond the initial price and calculate the full Total Cost of Ownership, prioritizing robust, reliable equipment to avoid unexpected and costly future repairs.

A thorough evaluation transforms a simple purchase into a strategic investment in your lab's future success.

Summary Table:

| Criteria Category | Key Factors to Consider |

|---|---|

| Product Quality | ISO 9001 certification, material quality, engineering robustness |

| Performance | Technical specs (resolution, sensitivity, throughput), validated data |

| Compliance | CE marking, FDA regulations (e.g., 21 CFR Part 11) |

| Manufacturer Support | Warranty terms, service contracts, spare parts availability, training |

| Company Reputation | User testimonials, case studies, financial stability |

| Trade-offs | Cost vs. quality, innovation vs. reliability, convenience vs. specialization |

Ready to make a strategic investment in your lab's future? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to meet the rigorous demands of modern laboratories. Our commitment to product excellence, comprehensive after-sales support, and deep technical expertise ensures your operations run smoothly and efficiently.

Contact us today to discuss your specific needs and discover how KINTEK can become your trusted partner in achieving reliable and accurate results.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Double Plate Heating Press Mold for Lab

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- What is the difference between a lab oven and a furnace? Choose the Right Tool for Your Thermal Process

- How do you prepare a sample for XRF? Achieve Accurate and Reliable Analysis

- Can a reaction have multiple reaction types? Understand the Patterns and Processes

- What are zeolites advantages and disadvantages? Maximize Molecular Selectivity and Efficiency

- What is the purpose of an ice water bath in microwave pyrolysis? Enhance Bio-Oil Yield and Sample Integrity

- What is the pressure in a sputter coater? Master Base vs. Working Pressure for Superior Coatings

- What are the feedstocks for biochar production? Choose the Right Material for Your Application