The definitive instrument used to measure the partial pressure of individual residual gases within a vacuum is a Residual Gas Analyzer (RGA). An RGA is a compact mass spectrometer specifically designed to operate in and analyze the low-pressure environment of a vacuum chamber, giving you a detailed breakdown of its chemical composition.

While a standard vacuum gauge tells you the total pressure in your system, it offers no insight into what gases are contributing to that pressure. An RGA solves this by providing a compositional "fingerprint" of your vacuum, turning a simple pressure value into a powerful diagnostic and process control tool.

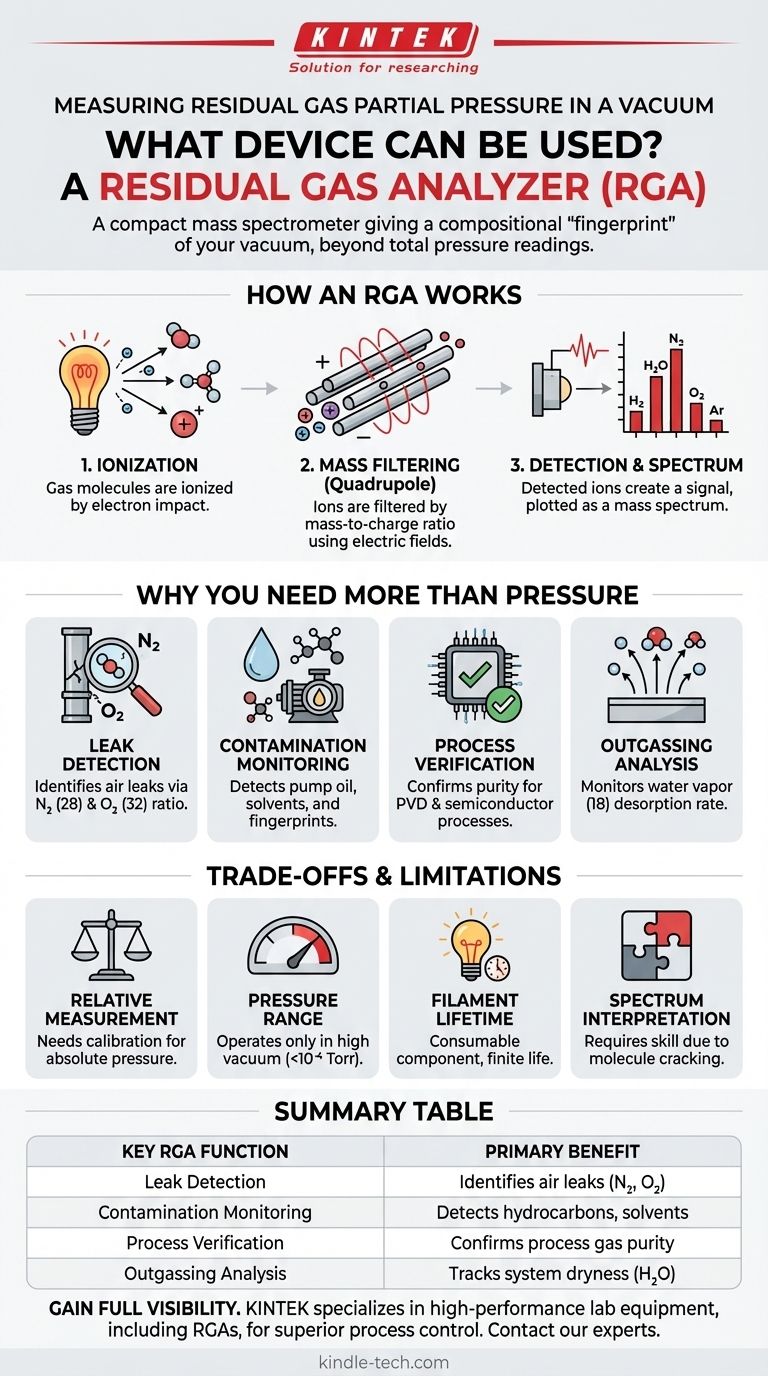

How a Residual Gas Analyzer Works

An RGA does not measure all gases at once. Instead, it systematically identifies molecules by their mass-to-charge ratio, building a complete picture of the vacuum environment one mass at a time.

The Principle: From Molecule to Signal

The core function of an RGA is to convert neutral gas molecules into a measurable electrical signal that corresponds to a specific mass. This is accomplished in three main steps.

Step 1: Ionization

Gas molecules from the vacuum chamber drift into the RGA's ion source. Here, a hot filament emits a stream of electrons, which collide with the gas molecules and knock an electron off, creating positively charged ions.

Step 2: Mass Filtering (The Quadrupole)

These new ions are accelerated into a mass filter, most commonly a quadrupole. This device consists of four parallel metal rods. A combination of radio frequency (RF) and direct current (DC) voltages is applied to these rods, creating a complex electric field that only allows ions of a single, specific mass-to-charge ratio to have a stable path and pass through.

All other ions with different masses are deflected into the rods and neutralized.

Step 3: Detection and Spectrum

The ions that successfully navigate the filter strike a detector, typically a Faraday cup or an electron multiplier. This generates a tiny electrical current proportional to the number of ions hitting it.

By systematically sweeping the voltages on the quadrupole rods, the RGA scans through a range of masses. The resulting data is plotted as a spectrum, showing the partial pressure (or ion current) for each mass, creating a bar chart of the molecules in your vacuum.

Why You Need More Than Just a Pressure Reading

Knowing the composition of your vacuum is critical for troubleshooting, quality assurance, and process control. An RGA provides direct, actionable insights that a total pressure gauge cannot.

Leak Detection

If your system cannot reach its target pressure, an RGA can immediately identify the cause. The classic signature of an air leak is the presence of peaks at mass 28 (Nitrogen) and mass 32 (Oxygen) in their characteristic ~4:1 atmospheric ratio.

Contamination Monitoring

RGAs are exceptionally sensitive to contaminants. They can detect hydrocarbons from pump oil backstreaming, solvents from improper cleaning, or even outgassing from fingerprints, allowing you to pinpoint and eliminate sources of contamination that could ruin a sensitive process.

Process Verification

In processes like physical vapor deposition (PVD) or semiconductor manufacturing, the purity of the vacuum is paramount. An RGA verifies that unwanted reactive gases like water vapor or oxygen have been sufficiently removed and confirms the precise partial pressure of the intended process gas, such as Argon.

Outgassing Analysis

The most common residual gas in a high-vacuum system is water vapor (mass 18), which slowly desorbs from the chamber walls. An RGA allows you to monitor the rate of this outgassing and determine when your system is sufficiently "dry" and ready for your process.

Understanding the Trade-offs and Limitations

While powerful, an RGA is a sophisticated instrument with operational nuances that must be respected.

Relative vs. Absolute Measurement

An RGA provides highly accurate relative measurements, showing you the ratio of different gases. However, to get a precise, absolute partial pressure reading in Torr or mbar, the RGA must be calibrated for each specific gas species, as its sensitivity varies.

Operational Pressure Range

RGAs cannot operate at atmospheric pressure. They have a maximum operating pressure, typically around 10⁻⁴ Torr. Exposing the RGA's hot filament to higher pressures will cause it to burn out rapidly.

Filament Lifetime

The ion source filament is a consumable component with a finite lifetime. Its lifespan is reduced by operating at higher pressures or with reactive gases.

Spectrum Interpretation Requires Skill

An RGA spectrum is not always straightforward. Larger molecules can break apart during ionization into smaller, charged fragments, a phenomenon known as "cracking." For example, carbon dioxide (CO₂, mass 44) will also produce peaks for CO (28), O (16), and C (12), which can overlap with other gases.

Making the Right Choice for Your Goal

Before investing in an RGA, it's critical to define your primary need for vacuum analysis.

- If your primary focus is knowing the total pressure: A standard vacuum gauge (like a Pirani, thermocouple, or ion gauge) is the correct, cost-effective tool.

- If your primary focus is troubleshooting a leak or contamination issue: An RGA is the essential diagnostic tool for identifying the specific gases causing the problem.

- If your primary focus is controlling a gas-sensitive process: An RGA is non-negotiable for real-time monitoring, ensuring process purity and repeatability.

Ultimately, an RGA transforms your vacuum system from an opaque box into a transparent, controllable environment.

Summary Table:

| Key RGA Function | Primary Benefit |

|---|---|

| Leak Detection | Identifies air leaks via Nitrogen (28) and Oxygen (32) peaks |

| Contamination Monitoring | Detects hydrocarbons, solvents, and other contaminants |

| Process Verification | Confirms purity and monitors process gas partial pressures |

| Outgassing Analysis | Tracks water vapor and other desorbed gases to ensure system readiness |

Ready to gain full visibility into your vacuum processes? An RGA is essential for precise diagnostics and quality control in any laboratory setting. KINTEK specializes in high-performance lab equipment, including Residual Gas Analyzers, to help you achieve superior process control and contamination-free results. Contact our experts today to find the perfect RGA solution for your specific application—from leak detection to advanced thin-film deposition.

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Shaking Incubators for Diverse Laboratory Applications

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is basic lining material? The Key to High-Temperature Chemical Compatibility

- What is the primary purpose of a cold trap in precision gas measurement? Ensure Data Purity with KINTEK Solutions

- What are the parts of a Rotavap? Master the Core System for Efficient Solvent Evaporation

- Why must a laboratory vacuum pump be used to evacuate a PM-HIP capsule before it is sealed? Ensure Material Integrity

- Why is Boron Nitride or graphite paper used in hot-press sintering? Ensure Smooth Demolding & Protect Your Molds

- How do you make quartz tubes? A Guide to High-Purity Fabrication for Demanding Applications

- What is the function of quartz ampoules in sulfide electrolyte synthesis? Ensure High-Purity Material Containment

- What are the primary reasons for selecting high-purity dense alumina as the inner tube material? Optimize Lab Safety