At its core, a sieve test determines the particle size distribution of a material sample. It is a fundamental particle analysis method used for quality control, separating a granular material or powder into fractions based on size. This allows manufacturers and researchers to understand the range of particle sizes present within a given batch.

A sieve test provides more than just a measurement; it delivers a clear and reliable picture of a material's physical consistency. By quantifying the particle size distribution, you gain the ability to verify product quality, control manufacturing processes, and ensure your material meets precise specifications.

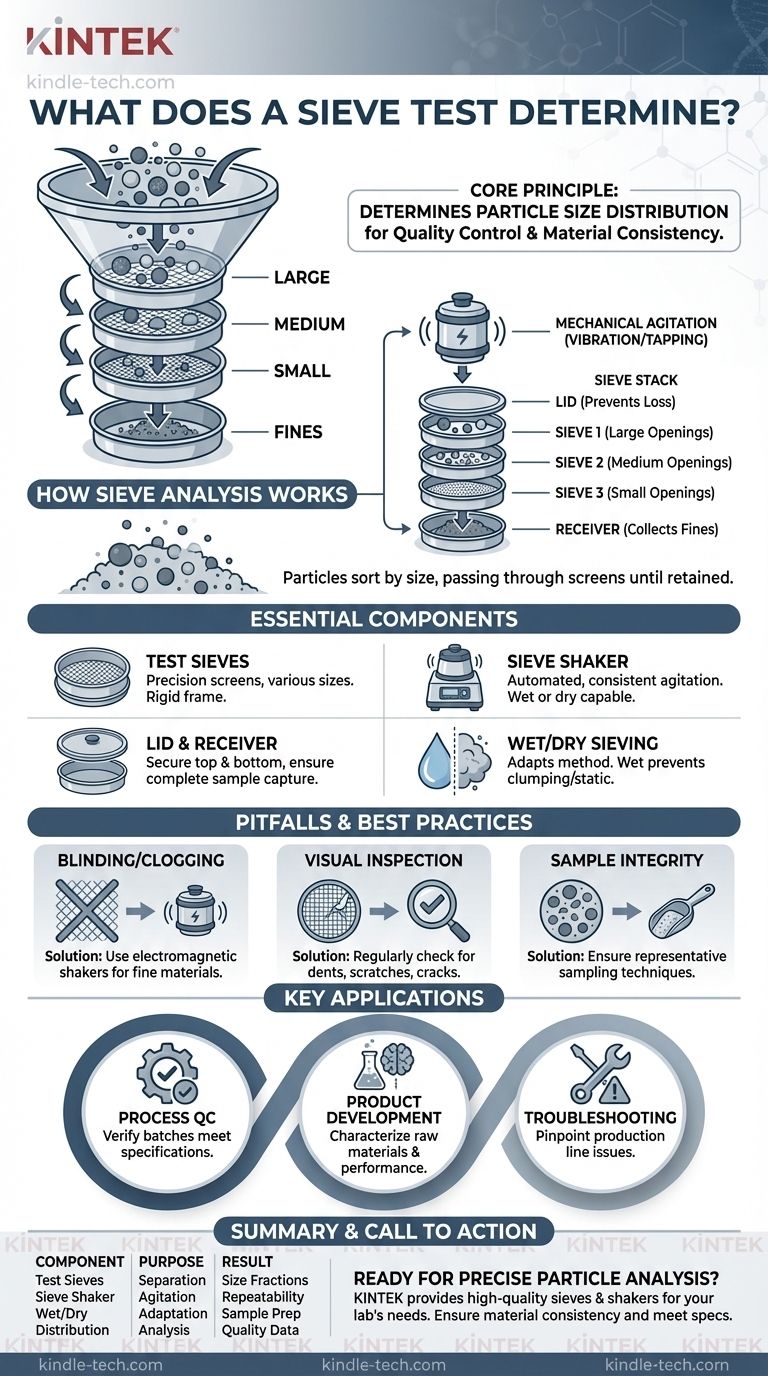

How Sieve Analysis Works: The Core Principle

A sieve test, also known as a gradation test, functions by passing a sample of material through a series of screens with progressively smaller openings. The process provides a quantitative breakdown of the particle sizes within that sample.

The Sieve Stack

The foundation of the test is a stack of test sieves. Each sieve is a rigid frame holding a mesh or screen of a specific, certified opening size. These are arranged vertically, from the largest opening at the top to the smallest opening at the bottom.

Mechanical Agitation

This stack of sieves is placed in a sieve shaker. This device provides consistent, repeatable agitation—either through vibration or a tapping motion—which causes the particles to move and find their way through the mesh openings.

The Separation Process

As the shaker operates, particles pass downward through the stack until they are retained on a sieve with mesh openings smaller than their diameter. This effectively sorts the original sample into different size fractions, with each sieve holding particles within a specific size range.

The Final Collection

A solid pan, known as a receiver, is placed at the very bottom of the stack. It collects all the particles that are fine enough to pass through even the smallest mesh size, ensuring the entire sample is accounted for.

The Essential Components of a Sieve Test

To achieve accurate and repeatable results, a specific set of standardized equipment is required. Each component plays a critical role in the integrity of the analysis.

Test Sieves

The sieves themselves are precision instruments. They consist of a rigid frame, typically with a diameter of 8 inches, and a carefully woven wire mesh. The frame depth can be "full height" (2 inches) or "half height" (1 inch) to accommodate different sample volumes.

The Sieve Shaker

The shaker automates the process, providing a uniform motion that is essential for reproducibility. Modern sieve shakers often feature touchscreen controls and software to manage test parameters and can be adapted for both wet and dry samples.

The Lid

A lid is placed on the top sieve before agitation begins. Its sole purpose is to prevent any loss of the sample material during the shaking process, which would skew the final results.

Understanding the Pitfalls and Best Practices

While the concept is straightforward, several factors can compromise the accuracy of a sieve test. Awareness of these issues is key to obtaining reliable data.

Sieve Blinding and Clogging

Fine particles can sometimes block or "blind" the mesh openings, preventing other particles from passing through. For very fine materials (as small as 5μm), specialized electromagnetic sieve shakers can create micro-vibrations to help clear the mesh and prevent this issue.

The Importance of Visual Inspection

Before every use, sieves must be visually inspected. Dents or scratches in the mesh can alter the size of the openings, while cracks in the epoxy that secures the mesh can allow particles to bypass the screen entirely. Either defect will lead to inaccurate results.

Sample Integrity

The small sample used for the test must be representative of the entire batch of material. Poor sampling techniques will produce a result that does not accurately reflect the overall product quality.

Wet vs. Dry Sieving

Certain materials may agglomerate or be affected by static electricity when dry. In these cases, wet sieving, which involves introducing water or another liquid, is necessary to break up clumps and ensure individual particles are analyzed correctly.

Making the Right Choice for Your Goal

The purpose of a sieve test is not just to generate data, but to gain actionable insight into your material. How you use the results depends entirely on your objective.

- If your primary focus is process quality control: Use the particle size distribution to verify that each production batch meets required specifications and to identify any deviations that signal a process issue.

- If your primary focus is product development: Characterize raw materials to understand how particle size will affect the performance, texture, or solubility of your final product.

- If your primary focus is troubleshooting production failures: Analyze samples from different stages of the manufacturing line to pinpoint where and why particle size characteristics are changing unexpectedly.

Ultimately, sieve testing empowers you to make data-driven decisions that ensure the physical properties of your material are precisely what they need to be.

Summary Table:

| Sieve Test Component | Purpose |

|---|---|

| Test Sieves | Precision screens that separate particles by size. |

| Sieve Shaker | Provides consistent agitation for accurate, repeatable results. |

| Wet/Dry Sieving | Adapts the method for different materials (e.g., clumping or static-prone). |

| Particle Distribution | The core result, showing the percentage of particles in each size range. |

Ready to achieve precise particle analysis in your lab?

KINTEK specializes in high-quality lab equipment and consumables, including precision test sieves and reliable sieve shakers designed for accurate particle size distribution analysis. Whether your focus is quality control, product development, or troubleshooting, our solutions help you ensure material consistency and meet strict specifications.

Contact us today using the form below to discuss your laboratory's specific needs and discover how KINTEK can enhance your sieving processes.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What is the function of a sieve in a laboratory? Master Particle Size Analysis for Quality Control

- Are different sieves used to separate different mixtures? Choose the Right Sieve for Your Mixture

- What are the advantages of the sieve method? Achieve Fast, Reliable Particle Size Analysis

- How is sieving important? The Critical Role of Particle Size Analysis in Quality Control

- What are the limitations of particle size determination by sieving? Uncover Key Drawbacks and Alternative Methods

- What can be separated by sieving? A Guide to Particle Size Separation for Various Materials

- What is the size range for sieving? From 125mm Gravel to 20µm Powders

- What is sieving used for in science? A Guide to Particle Size Analysis & Control