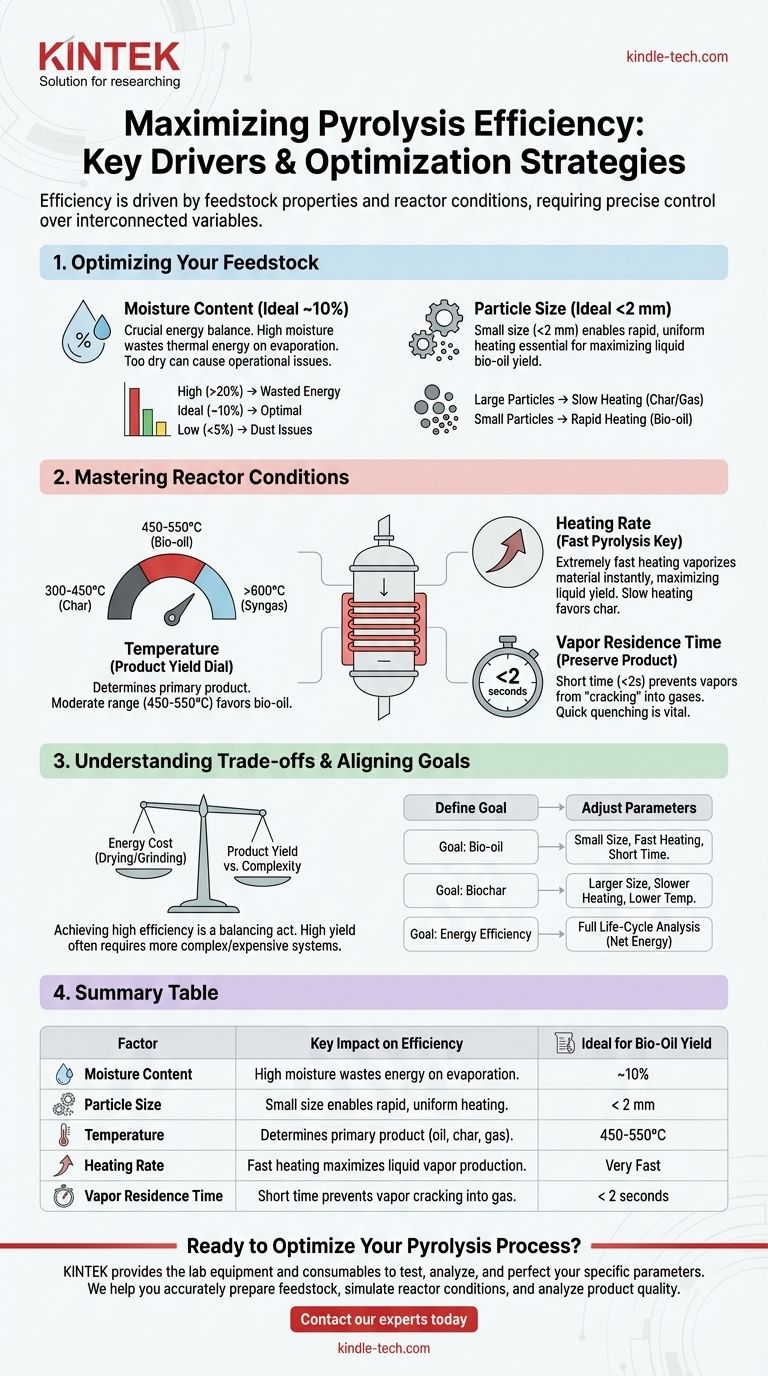

Fundamentally, the efficiency of the pyrolysis process is dictated by the physical characteristics of your feedstock and the precise conditions within the reactor. The most critical factors are the feedstock's moisture content and particle size, as these directly influence how effectively heat can be transferred to trigger the desired chemical transformation.

Successful pyrolysis is not about a single magic setting. It is about carefully controlling a system of interconnected variables—feedstock preparation and reactor dynamics—to steer the chemical reaction toward your desired product, whether that is bio-oil, biochar, or gas.

Optimizing Your Feedstock: The First Step to Efficiency

Before the feedstock ever enters the reactor, its properties have already set a ceiling for potential process efficiency. Proper preparation is non-negotiable.

The Critical Role of Moisture Content

The ideal moisture content for most pyrolysis systems is around 10%. This is a crucial energy balance.

If moisture is too high, the process must expend a significant amount of thermal energy just to boil the water off. This energy is wasted and does not contribute to the pyrolysis reaction itself, drastically reducing the net energy efficiency of the system.

Conversely, if the feedstock is excessively dry, especially if it is a fine powder, it can create operational problems. It may become airborne and carried out of the reactor with the vapor stream as dust, failing to convert into valuable products.

Why Particle Size Dictates Reaction Speed

For processes aiming to maximize liquid bio-oil, small particle sizes (typically under 2 mm) are required. This is a matter of heat transfer physics.

Small particles have a very high surface-area-to-volume ratio. This allows heat to penetrate the entire particle almost instantly and uniformly.

This rapid and even heating is the key to maximizing the yield of liquid oil. It prevents slower, secondary reactions that convert the valuable vapors into less-desirable char and gas.

Mastering Reactor Conditions: The Core of the Process

Once the feedstock is optimized, control shifts to the reactor itself. The temperature, heating rate, and time the vapors spend in the hot zone are the primary levers for controlling the final product slate.

Temperature: The Product Yield Dial

Temperature is the single most important variable for determining what products you will get.

- Low Temperatures (300-450°C): Slower pyrolysis at lower temperatures favors the production of solid biochar.

- Moderate Temperatures (450-550°C): This is the typical range for "fast pyrolysis," which is optimized to break down biomass into vapors that can be condensed into liquid bio-oil.

- High Temperatures (>600°C): Very high temperatures cause the pyrolysis vapors to thermally "crack" into simpler, non-condensable molecules, maximizing the yield of syngas.

Heating Rate: The Key to Fast Pyrolysis

Closely related to particle size, the heating rate is how quickly the feedstock reaches the target pyrolysis temperature. To maximize liquid yield, an extremely fast heating rate is essential.

Slow heating allows the biomass to "cook," giving it time to rearrange its structure and form more char. Rapid heating instantly vaporizes the material, creating the conditions necessary for high liquid oil yields.

Vapor Residence Time: Preserving Your Product

This refers to the amount of time the hot pyrolysis vapors spend inside the reactor before being cooled and collected. For maximum bio-oil yield, a very short vapor residence time (typically less than 2 seconds) is crucial.

If the vapors linger in the hot reaction zone, they will start to break down (crack) into permanent gases, reducing your final liquid yield. The goal is to get the vapors out and "quench" them quickly to condense them into a stable bio-oil.

Understanding the Trade-offs

Achieving high efficiency is a balancing act, and optimizing for one parameter often involves a cost elsewhere.

The Energy Cost of Preparation

Drying and grinding feedstock requires energy. A truly efficient process must account for this "parasitic load." A system that produces a high yield of bio-oil might not be energy-positive if it consumes enormous amounts of electricity or fuel to prepare its feedstock.

Product Yield vs. Process Complexity

Achieving the rapid heating rates and short vapor residence times needed for high oil yields often requires more complex and expensive reactor designs, such as a fluidized bed reactor. Slower pyrolysis systems that produce more char are often simpler and cheaper to build and operate.

Aligning Your Process with Your Goal

Your definition of "efficiency" depends entirely on your desired product. Use these principles to guide your decisions.

- If your primary focus is maximizing bio-oil yield: Prioritize very small particle sizes, rapid heating to around 500°C, and a short vapor residence time to quickly quench the vapors.

- If your primary focus is producing high-quality biochar: Use slower heating rates, slightly larger feedstock, and lower peak temperatures to ensure a complete but gradual conversion to char.

- If your primary focus is overall energy efficiency: You must perform a full life-cycle analysis that subtracts the energy used for feedstock drying and grinding from your final energy product output.

By methodically controlling these interconnected variables, you can steer the pyrolysis reaction to efficiently produce your desired outcome.

Summary Table:

| Factor | Key Impact on Efficiency | Ideal for Bio-Oil Yield |

|---|---|---|

| Moisture Content | High moisture wastes energy on evaporation. | ~10% |

| Particle Size | Small size enables rapid, uniform heating. | < 2 mm |

| Temperature | Determines primary product (oil, char, gas). | 450-550°C |

| Heating Rate | Fast heating maximizes liquid vapor production. | Very Fast |

| Vapor Residence Time | Short time prevents vapor cracking into gas. | < 2 seconds |

Ready to Optimize Your Pyrolysis Process?

Whether your goal is to maximize bio-oil, produce high-quality biochar, or achieve overall energy efficiency, precise control over feedstock and reactor conditions is non-negotiable. KINTEK specializes in providing the lab equipment and consumables you need to test, analyze, and perfect your pyrolysis parameters.

We help you:

- Accurately prepare and characterize feedstock.

- Simulate and control critical reactor conditions.

- Analyze product yields and quality with precision.

Don't leave your process efficiency to chance. Contact our experts today to discuss how KINTEK's solutions can help you achieve your specific pyrolysis goals.

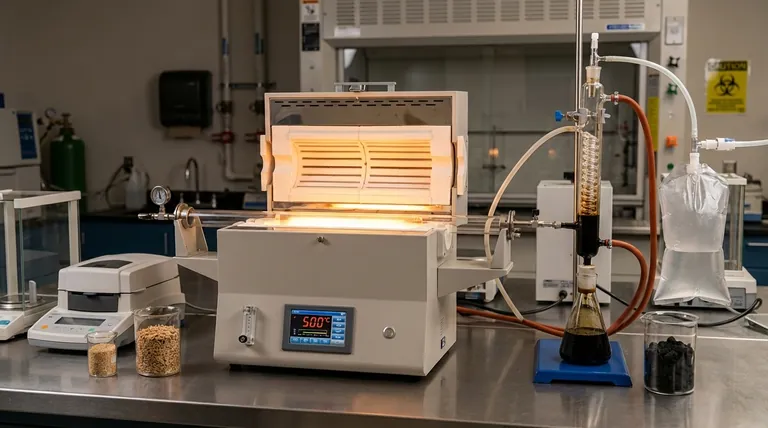

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis