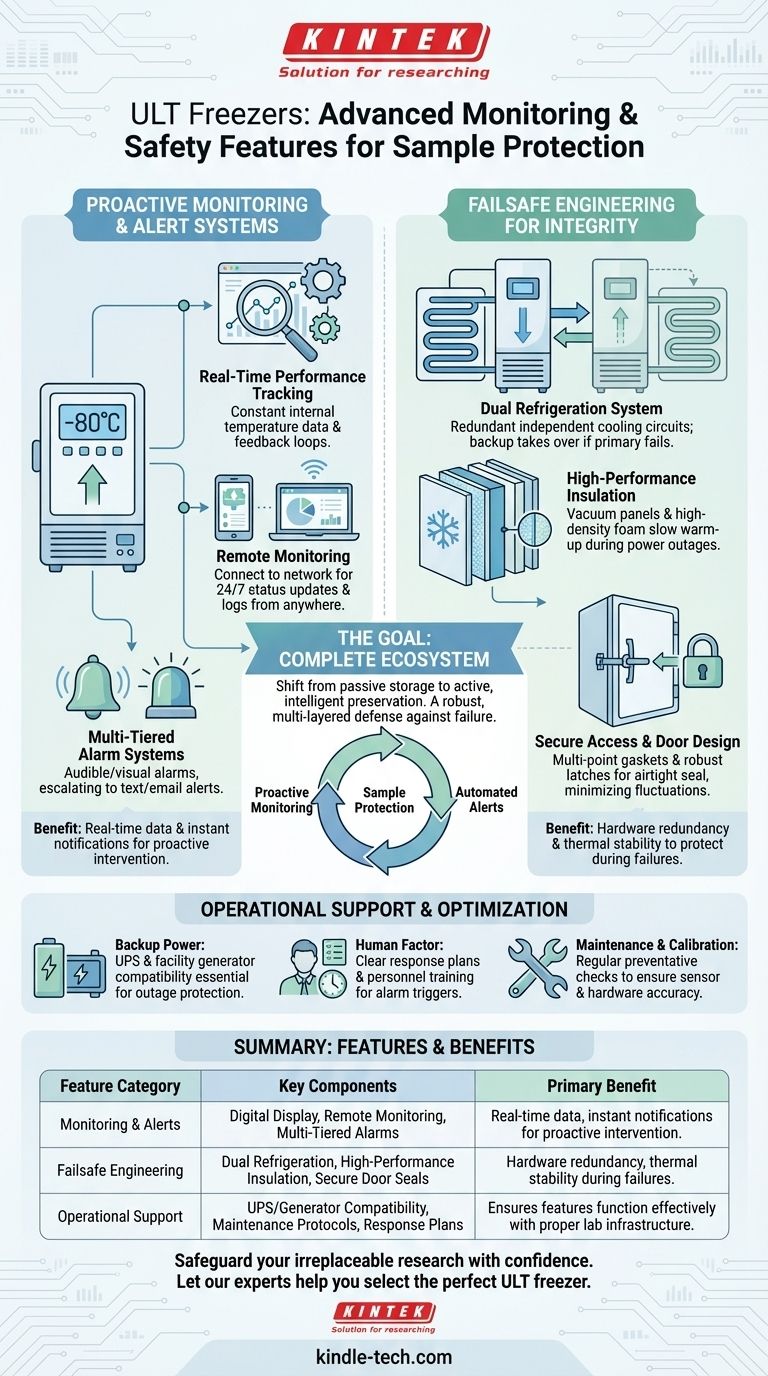

To protect irreplaceable samples, modern Ultra-Low Temperature (ULT) freezers are engineered with a sophisticated suite of integrated monitoring and safety features. These systems go beyond simple cooling, incorporating real-time data tracking, intelligent alarm systems that can send remote notifications, and redundant hardware like dual refrigeration systems to create a robust, multi-layered defense against equipment failure and temperature deviations.

The core principle has shifted from passive cold storage to active, intelligent preservation. Modern ULT freezers are designed as a complete ecosystem of proactive monitoring, automated alerts, and failsafe hardware to prevent catastrophic sample loss before it happens.

Proactive Monitoring and Alert Systems

The first line of defense in sample protection is information. Modern freezers provide constant, accessible data on their operational status, allowing for immediate intervention.

Real-Time Performance Tracking

Nearly all modern ULT freezers feature a prominent digital display panel showing the precise internal temperature. This is managed by a sophisticated control system using internal sensors and feedback loops to maintain a stable environment, typically around -80°C.

Remote Monitoring Capabilities

Many advanced units are equipped with smart technology, allowing lab managers to connect the freezer to a network. This enables them to track performance, view temperature logs, and receive status updates in real-time from a computer or mobile device, no matter their location.

Multi-Tiered Alarm Systems

If a parameter deviates from the set range, a multi-stage alarm system is activated. This typically begins with an audible and visual alarm on the unit itself and can escalate to sending automated text or email alerts to designated personnel, ensuring critical issues are never missed.

Failsafe Engineering for Sample Integrity

Beyond monitoring, the physical design of the freezer includes critical redundancies and structural features to protect samples during adverse events like a power failure or component malfunction.

The Critical Role of Dual Refrigeration

A key safety feature in high-end ULT freezers is a dual refrigeration system. This design incorporates two independent cooling circuits. If one primary system fails, the backup system automatically takes over, maintaining the target temperature and preventing any damage to the samples inside.

High-Performance Insulation

Modern freezers utilize advanced vacuum insulated panels and high-density foam insulation. This superior insulation dramatically slows the rate of temperature change (warm-up time) during a power outage, providing a crucial buffer of several hours for corrective action to be taken.

Secure Access and Door Design

To maintain temperature stability, freezers are designed with multi-point gaskets and robust door latches to create an airtight seal. This minimizes frost buildup and reduces the temperature fluctuations that occur from frequent or incomplete door closures.

Understanding Operational Trade-offs

While these features provide immense security, their effectiveness depends on the lab's infrastructure and protocols. Relying solely on the freezer's features without supporting them is a common pitfall.

The Need for Backup Power

Remote alerts and dual refrigeration systems are only effective if the freezer has power. A freezer connected to an uninterruptible power supply (UPS) and a facility backup generator is the gold standard for protecting against power outages.

The Human Factor

Features like remote monitoring are invaluable, but they require a clear and tested response plan. Designated personnel must know their responsibilities when an alarm is triggered, day or night.

Maintenance and Calibration

Sensors and refrigeration systems can drift over time. Regular preventative maintenance and temperature calibration are essential to ensure the monitoring systems are accurate and the hardware is performing optimally.

Making the Right Choice for Your Goal

The necessary level of protection depends directly on the value and irreplaceability of the samples being stored.

- If your primary focus is protecting highly valuable or irreplaceable samples: Prioritize a freezer with a dual refrigeration system and integrated remote monitoring.

- If your primary focus is managing a large fleet of freezers: Remote monitoring is essential for centralized oversight and efficient response to any issues across the lab.

- If your primary focus is standard long-term storage of less critical samples: A unit with robust insulation and a reliable, locally-audible alarm system provides a solid baseline of protection.

Ultimately, modern freezer technology provides the tools to build a powerful defense for your critical scientific work.

Summary Table:

| Feature Category | Key Components | Primary Benefit |

|---|---|---|

| Monitoring & Alerts | Digital Display, Remote Monitoring, Multi-Tiered Alarms | Real-time data and instant notifications for proactive intervention |

| Failsafe Engineering | Dual Refrigeration, High-Performance Insulation, Secure Door Seals | Hardware redundancy and thermal stability to protect during failures |

| Operational Support | UPS/Generator Compatibility, Maintenance Protocols, Response Plans | Ensures features function effectively with proper lab infrastructure |

Safeguard your irreplaceable research with confidence. Modern ULT freezers are a critical investment in sample integrity. At KINTEK, we specialize in providing reliable lab equipment, including advanced ultra-low temperature freezers with the monitoring and safety features your laboratory demands. Let our experts help you select the perfect freezer to meet your specific sample storage needs. Contact us today for a personalized consultation!

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity