Beyond the jeweler's display, diamonds are one of the most critical materials in modern industry. Their unparalleled physical properties make them indispensable for a wide range of applications, including high-precision cutting tools, advanced electronics, optical systems, and scientific research.

The core reason for the industrial use of diamonds is not their beauty, but their unique combination of extreme physical traits. Their unmatched hardness, exceptional thermal conductivity, and optical clarity solve engineering challenges that no other material can.

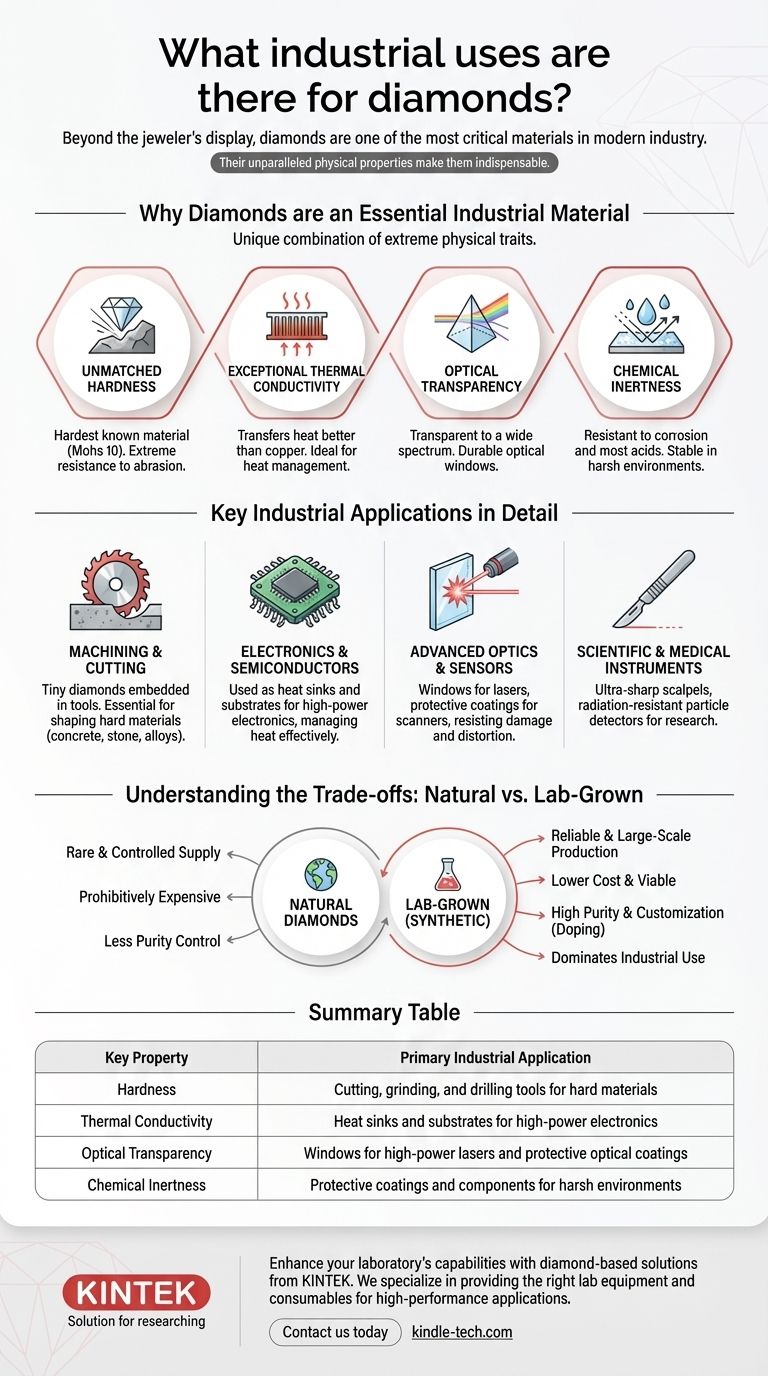

Why Diamonds are an Essential Industrial Material

Before looking at specific applications, it's crucial to understand the fundamental properties that make diamonds so valuable to engineers and scientists. These traits are rarely found together in a single material.

Unmatched Hardness

A diamond is the hardest known natural material, scoring a 10 on the Mohs hardness scale. This extreme resistance to scratching and abrasion is its most famous industrial asset.

This property makes it the ultimate abrasive for cutting, grinding, and drilling other hard materials with high precision.

Exceptional Thermal Conductivity

Diamonds are remarkable thermal conductors, transferring heat more effectively than familiar materials like copper or silver. They can rapidly draw heat away from a concentrated source.

This makes them ideal for use as heat sinks in high-power electronics, preventing sensitive components from overheating and failing.

Optical Transparency

High-purity diamonds are transparent to a wide spectrum of light, from ultraviolet to far-infrared. This broad transmission window is a significant advantage over glass or other optical materials.

This allows them to be used as durable, protective windows for sensors and high-power lasers that would damage lesser materials.

Chemical Inertness

Diamonds are highly resistant to chemical corrosion and do not react with most acids or other corrosive substances.

This stability makes them suitable for protective coatings in harsh environments and for biomedical implants that must not react with the body.

Key Industrial Applications in Detail

These unique properties translate directly into critical, high-performance applications across multiple sectors.

Machining and Cutting

This is the most widespread industrial use of diamonds. Tiny diamonds, often synthetic, are embedded into saw blades, drill bits, and grinding wheels.

These tools are essential for shaping and cutting everything from concrete and stone in construction to ultra-hard ceramics and metal alloys in manufacturing.

Electronics and Semiconductors

As electronics become smaller and more powerful, managing heat is a primary challenge. Thin layers of lab-grown diamond are used as substrates or heat spreaders for high-frequency processors and power transistors.

This application leverages the diamond's thermal conductivity to keep critical components cool, ensuring reliability and performance.

Advanced Optics and Sensors

In demanding optical systems, a material must withstand intense energy without degrading. Diamonds are used to create windows for high-power industrial lasers and scientific instruments.

Their hardness also makes them the perfect material for protective coatings on scanner windows and lenses, preventing scratches that would distort readings.

Scientific and Medical Instruments

The unique properties of diamonds enable cutting-edge research and medical procedures. Their hardness allows for the creation of ultra-sharp surgical scalpels.

In high-energy physics, specially engineered diamonds are used as radiation-resistant particle detectors, such as those at the Large Hadron Collider.

Understanding the Trade-offs: Natural vs. Lab-Grown

The vast majority of diamonds used in industry are not mined from the earth. They are lab-grown (synthetic) diamonds, which offer critical advantages for technical applications.

Cost and Availability

Natural, gem-quality diamonds are rare, and their supply is tightly controlled, making them prohibitively expensive for most industrial uses.

Lab-grown diamonds can be produced reliably and in large quantities, dramatically lowering the cost and making their use in tools and electronics economically viable.

Purity and Customization

The lab-grown process allows for precise control over a diamond's purity and properties. Scientists can create diamonds with fewer imperfections than most natural stones.

Furthermore, they can be "doped" with specific elements like boron or nitrogen to alter their electrical properties, turning them into high-performance semiconductors tailored for specific electronic devices.

Making the Right Choice for the Application

The specific property being utilized determines the diamond's role in any given technology. Understanding this link is key to appreciating its versatility.

- If your primary focus is mechanical abrasion and cutting: You are leveraging diamond's extreme hardness to shape or machine other tough materials.

- If your primary focus is high-power electronics: You are relying on diamond's superior thermal conductivity to manage heat and prevent component failure.

- If your primary focus is advanced optics or sensors: You are utilizing diamond's broad optical transparency and chemical stability for durable, high-performance windows and coatings.

Ultimately, a diamond's industrial value is a direct result of its physics, making it an irreplaceable material for solving modern engineering problems.

Summary Table:

| Key Property | Primary Industrial Application |

|---|---|

| Hardness | Cutting, grinding, and drilling tools for hard materials |

| Thermal Conductivity | Heat sinks and substrates for high-power electronics |

| Optical Transparency | Windows for high-power lasers and protective optical coatings |

| Chemical Inertness | Protective coatings and components for harsh environments |

Enhance your laboratory's capabilities with diamond-based solutions from KINTEK.

Diamonds are not just for jewelry; they are critical for precision, durability, and performance in demanding applications. Whether you need high-performance cutting tools, efficient heat management for electronics, or durable optical components, KINTEK specializes in providing the right lab equipment and consumables to meet your needs.

Contact us today to discover how our diamond-based products can solve your specific engineering challenges and drive innovation in your work.

Visual Guide

Related Products

- 12 Inch 24 Inch High Precision Automatic Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

- CVD Diamond Dressing Tools for Precision Applications

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the best way to join stainless steel? A Guide to Welding, Brazing, and Fastening

- What machine do I need to make diamonds? HPHT vs. CVD Equipment Explained

- What is a diamond machine? Unlock the Power of Diamond Tooling for Your Toughest Materials

- What precautions should be taken when using hydraulic forming or cutting equipment to prepare stainless steel corrosion specimens? Ensure Accuracy.

- Is it illegal to make lab-grown diamonds? The Truth About Legality and Transparency